Q.3-Choose the correct answer of the following: 1. Injection molding is a type of: (a) Vacuum casting (b) Centrifugal casting (c) Squeeze casting (d) Die casting 2. From various casting processes, investment casting process is the suitable operation for manufacturing of: (a) Engine blocks (b) Gears (c) Jewelry (d) Car wheels (e) Pipes 3. The welding process by (GMAW) process is (a) Slower than, (b) Faster than, (c) at same speed as (d) at unpredictable speed. 4. The clearance angle is provided on the tools with a view to (a) Strength the tool. (b) Shear off the metal. (c) Prevent the tool from rubbing on workpiece (d) Facilitate easy flow of chips. 5. Chances of crack propagation are more in: (a) Cold working process (b) Hot working process (c) Both of the above (d) None of the above 6. For machining of carbide material which of the following tool will be preferred? (a) Zero rake angle tools. (b) Large positive rake angle tools. c) Large negative rake angle tools (d) Small point angle tools. 7. The rpm (N) of the shaft, diameter (d) =25 mm, cutting speed (v) =50 m/min is. (a) 63.69 (b) 636.9 (c) 3.925 (d) 3925. 8. In which of the following forging process poor material utilization occurs? (a) Open die (b) Closed die forging (c) Impression dies forging (d) Swaging forging 9. In the (GTAW) process. the thickness of chip is maximum at the beginning of the cut and minimum at th end of the cut (a) Up milling (b) down milling (c) Face milling (d) None of the Mentioned 10. Which of the following is not used because of the problem of handling extruded metal coming out through moving ram? (a) Direct extrusion (b) Indirect extrusion (c) Impact extrusion (d) Hydrostatic extrusion.

Q.3-Choose the correct answer of the following: 1. Injection molding is a type of: (a) Vacuum casting (b) Centrifugal casting (c) Squeeze casting (d) Die casting 2. From various casting processes, investment casting process is the suitable operation for manufacturing of: (a) Engine blocks (b) Gears (c) Jewelry (d) Car wheels (e) Pipes 3. The welding process by (GMAW) process is (a) Slower than, (b) Faster than, (c) at same speed as (d) at unpredictable speed. 4. The clearance angle is provided on the tools with a view to (a) Strength the tool. (b) Shear off the metal. (c) Prevent the tool from rubbing on workpiece (d) Facilitate easy flow of chips. 5. Chances of crack propagation are more in: (a) Cold working process (b) Hot working process (c) Both of the above (d) None of the above 6. For machining of carbide material which of the following tool will be preferred? (a) Zero rake angle tools. (b) Large positive rake angle tools. c) Large negative rake angle tools (d) Small point angle tools. 7. The rpm (N) of the shaft, diameter (d) =25 mm, cutting speed (v) =50 m/min is. (a) 63.69 (b) 636.9 (c) 3.925 (d) 3925. 8. In which of the following forging process poor material utilization occurs? (a) Open die (b) Closed die forging (c) Impression dies forging (d) Swaging forging 9. In the (GTAW) process. the thickness of chip is maximum at the beginning of the cut and minimum at th end of the cut (a) Up milling (b) down milling (c) Face milling (d) None of the Mentioned 10. Which of the following is not used because of the problem of handling extruded metal coming out through moving ram? (a) Direct extrusion (b) Indirect extrusion (c) Impact extrusion (d) Hydrostatic extrusion.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

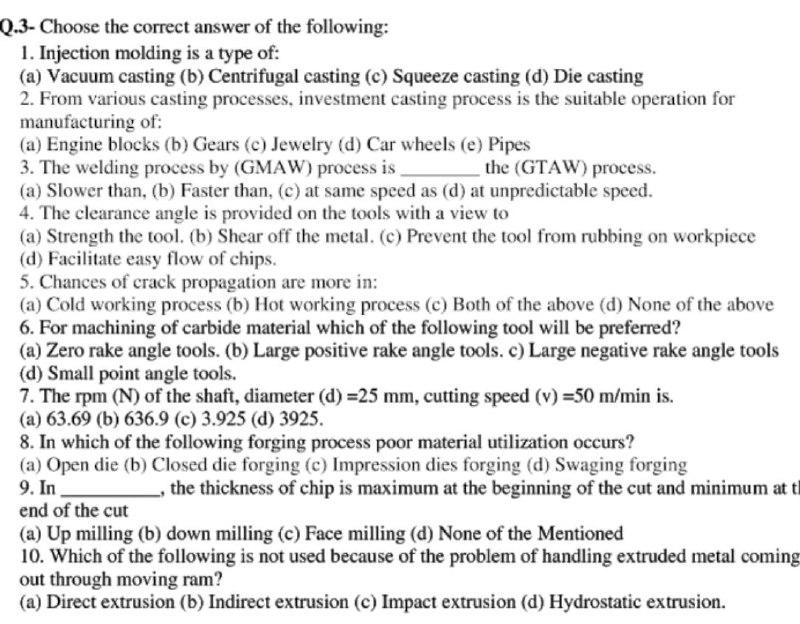

Please answer the MCQ's in the image

Transcribed Image Text:Q.3-Choose the correct answer of the following:

1. Injection molding is a type of:

(a) Vacuum casting (b) Centrifugal casting (c) Squeeze casting (d) Die casting

2. From various casting processes, investment casting process is the suitable operation for

manufacturing of:

(a) Engine blocks (b) Gears (c) Jewelry (d) Car wheels (e) Pipes

3. The welding process by (GMAW) process is

(a) Slower than, (b) Faster than, (c) at same speed as (d) at unpredictable speed.

4. The clearance angle is provided on the tools with a view to

(a) Strength the tool. (b) Shear off the metal. (c) Prevent the tool from rubbing on workpiece

(d) Facilitate easy flow of chips.

5. Chances of crack propagation are more in:

(a) Cold working process (b) Hot working process (c) Both of the above (d) None of the above

6. For machining of carbide material which of the following tool will be preferred?

(a) Zero rake angle tools. (b) Large positive rake angle tools. c) Large negative rake angle tools

(d) Small point angle tools.

7. The rpm (N) of the shaft, diameter (d) =25 mm, cutting speed (v) =50 m/min is.

(a) 63.69 (b) 636.9 (c) 3.925 (d) 3925.

8. In which of the following forging process poor material utilization occurs?

(a) Open die (b) Closed die forging (c) Impression dies forging (d) Swaging forging

9. In

the (GTAW) process.

the thickness of chip is maximum at the beginning of the cut and minimum at th

end of the cut

(a) Up milling (b) down milling (c) Face milling (d) None of the Mentioned

10. Which of the following is not used because of the problem of handling extruded metal coming

out through moving ram?

(a) Direct extrusion (b) Indirect extrusion (c) Impact extrusion (d) Hydrostatic extrusion.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY