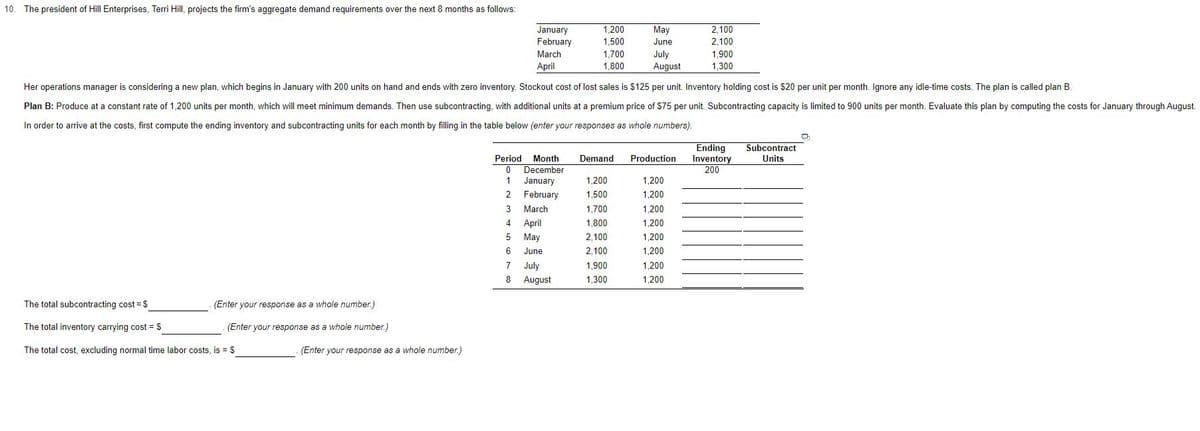

The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: 1200 January February May June 2,100 1,500 2,100 March 1,700 1.800 July August 1,900 1,300 April Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of lost sales is $125 per unit Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan B. Plan B: Produce at a constant rate of 1,200 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit Subcontracting capacity is limited to 900 units per month. Evaluate this plan by computing the costs for January through Augusi In order to arrive at the costs, first compute the ending inventory and subcontracting units for each month by filing in the table below (enter your responses as whole numbers). Ending Inventory 200 Subcontract Period Month O December 1 January 2 February 3 March 4 April 5 May 6 June 7 July 8 August Demand Production Units 1.200 1,200 1.500 1,200 1,700 1,200 1,800 1,200 5 2,100 1,200 2.100 1,200 1,900 1,200 1,300 1,200 The total subcontracting cost S (Enter your response as a whole number.) The total inventory carrying cost = S (Enter your response as a whole number.) The total cost, excluding normal time labor costs, is = $ (Enter your response as a whole number)

The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: 1200 January February May June 2,100 1,500 2,100 March 1,700 1.800 July August 1,900 1,300 April Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of lost sales is $125 per unit Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan B. Plan B: Produce at a constant rate of 1,200 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit Subcontracting capacity is limited to 900 units per month. Evaluate this plan by computing the costs for January through Augusi In order to arrive at the costs, first compute the ending inventory and subcontracting units for each month by filing in the table below (enter your responses as whole numbers). Ending Inventory 200 Subcontract Period Month O December 1 January 2 February 3 March 4 April 5 May 6 June 7 July 8 August Demand Production Units 1.200 1,200 1.500 1,200 1,700 1,200 1,800 1,200 5 2,100 1,200 2.100 1,200 1,900 1,200 1,300 1,200 The total subcontracting cost S (Enter your response as a whole number.) The total inventory carrying cost = S (Enter your response as a whole number.) The total cost, excluding normal time labor costs, is = $ (Enter your response as a whole number)

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

100%

Transcribed Image Text:10. The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows:

2,100

January

February

1,200

May

1,500

June

2,100

1,700

1,800

March

July

August

1,900

April

1,300

Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of lost sales is $125 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan B.

Plan B: Produce at a constant rate of 1,200 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit. Subcontracting capacity is limited to 900 units per month. Evaluate this plan by computing the costs for January through August.

In order to arrive at the costs, first compute the ending inventory and subcontracting units for each month by filling in the table below (enter your responses as whole numbers).

Ending

Inventory

200

Subcontract

Period Month

O December

January

Demand

Production

Units

1

1,200

1,200

February

1,500

1,200

3

March

1,700

1,200

April

1,800

1,200

5

May

2,100

1,200

6

June

2,100

1,200

7

July

1,900

1,200

8

August

1,300

1,200

The total subcontracting cost = $

(Enter your response as a whole number.)

The total inventory carrying cost = S

(Enter your response as a whole number.)

The total cost, excluding normal time labor costs, is = $

(Enter your response as a whole number.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 2 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.