(a)

Interpretation:

The liquidus temperature for

Concept Introduction:

On the temperature-composition graph of an alloy, the curve above which the alloy exists in the liquid phase is the liquidus curve. The temperature at this curve is at maximum and is known as liquidus temperature. In it, the crystals in the alloy can coexist with its melt in the

Answer to Problem 10.80P

Liquidus temperature,

Explanation of Solution

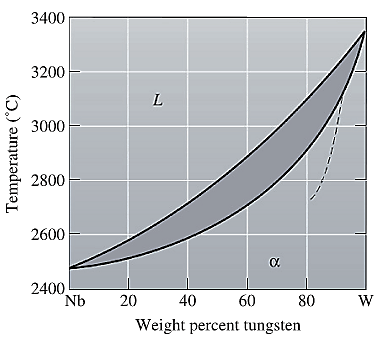

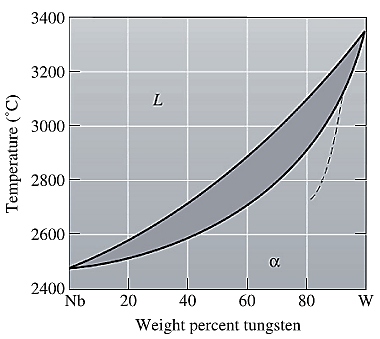

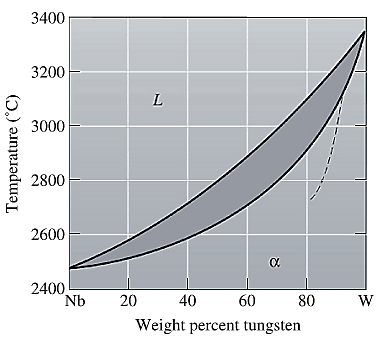

The equilibrium phase diagram for the Nb-W system is shown below as:

A straight line from

Liquidus temperature

(b)

Interpretation:

The solidus temperature for

Concept Introduction:

Solidus curve is the locus of the temperature on the temperature composition graph of an alloy, beyond which the alloy is completely in a solid phase. The temperature at this curve is minimum known as solidus temperature at which the crystals in the alloy can coexist with its melt in the thermodynamic equilibrium.

Answer to Problem 10.80P

Solidus temperature,

Explanation of Solution

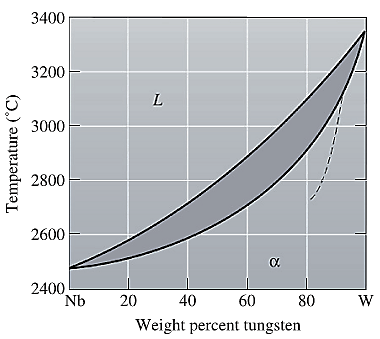

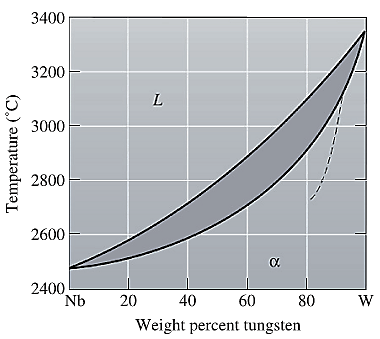

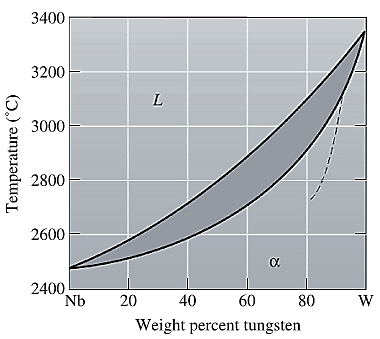

The equilibrium phase diagram for the Nb-W system is shown below as:

A straight line from

Solidus temperature

(c)

Interpretation:

The freezing range for

Concept Introduction:

Freezing range for an alloy is the difference of the liquidus and the solidus temperature of an alloy. In this range, the alloy melt starts to crystallize at liquidus temperature and solidifies when reaches solidus temperature.

Answer to Problem 10.80P

Freezing range,

Explanation of Solution

From part (a) and (b), the liquidus and solidus temperature for the given alloy is determined as:

The freezing range (FR) for this alloy composition will be:

(d)

Interpretation:

The composition of the first solid that is formed when

Concept Introduction:

On the temperature-composition graph of an alloy, the curve above which the alloy exists in the liquid phase is the liquidus curve. The temperature at this curve is maximum known as liquidus temperature at which the crystals in the alloy can coexist with its melt in the thermodynamic equilibrium.

Answer to Problem 10.80P

The composition of the first solid formed is

Explanation of Solution

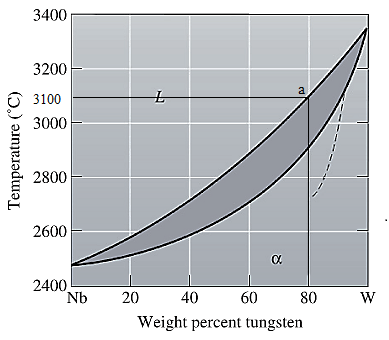

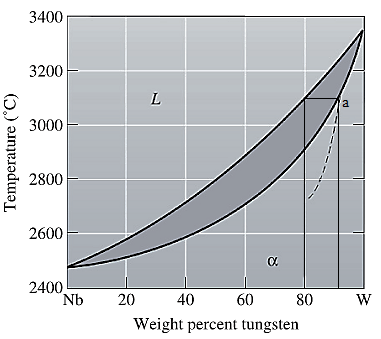

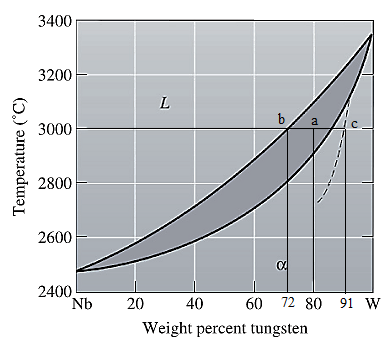

The equilibrium phase diagram for the Nb-W system is shown below as:

A straight line from

Point 'a' represents the composition of the first solid which is formed when

(e)

Interpretation:

The composition of the last liquid which is solidified when

Concept Introduction:

On the temperature-composition graph of an alloy, the curve above which the alloy exists in the liquid phase is the liquidus curve. The temperature at this curve is at maximum, is known as liquidus temperature at which the crystals in the alloy can coexist with its melt in the thermodynamic equilibrium.

Solidus curve is the locus of the temperature on the temperature composition graph of an alloy, beyond which the alloy is completely in a solid phase.

Between the solidus and liquidus curve, the alloy exits in a slurry form in which there is both crystals as well as alloy melt.

Solidus temperature is always less than or equal to the liquidus temperature.

Answer to Problem 10.80P

The composition of the last liquid solidified is

Explanation of Solution

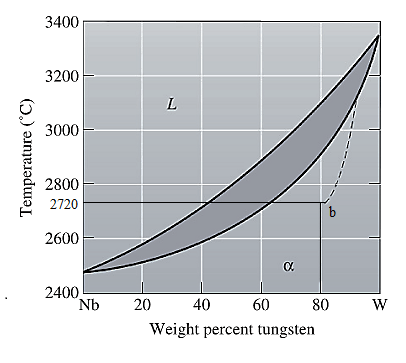

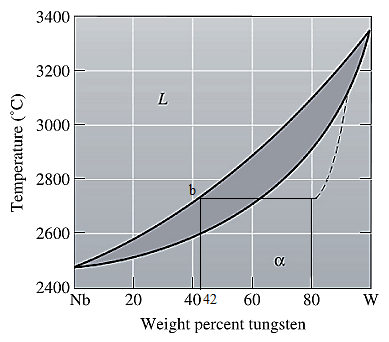

The equilibrium phase diagram for the Nb-W system is shown below as:

A straight line from

Point 'b' represents the composition of the last liquid which solidifies when

(f)

Interpretation:

The phases present, their compositions and their amounts for

Concept Introduction:

On the temperature-composition graph of an alloy, the curve above which the alloy exists in the liquid phase is the liquidus curve. The temperature at this curve is the maximum temperature at which the crystals in the alloy can coexist with its melt in the thermodynamic equilibrium.

Solidus curve is the locus of the temperature on the temperature composition graph of an alloy, beyond which the alloy is completely in a solid phase.

Between the solidus and liquidus curve, the alloy exits in a slurry form in which there is both crystals as well as alloy melt.

Solidus temperature is always less than or equal to the liquidus temperature.

Amount of each phase in wt% is calculated using lever rule. At a particular temperature and alloy composition, a tie line is drawn on the phase diagram of the alloy between the solidus and liquidus curve. Then the portion of the lever opposite to the phase whose amount is to be calculated is considered in the formula used as:

Answer to Problem 10.80P

Both solid, as well as liquid phases, are present at the given conditions.

Composition of the liquid phase present is

Composition of the solid phase present is

Amount of the liquid phase is

Amount of the solid phase is

Explanation of Solution

The equilibrium phase diagram for the Nb-W system is shown below as:

Now, draw a straight line from

Both the phases, solid and liquid are present at this condition. Point 'b' represents the liquid phase composition in wt% and point 'c' represents the solid phase composition in wt% on the dashed curve. From the above phase diagram:

To calculate the amount of liquid phase, lever 'ac' will be used and to calculate the amount of solid phase, lever 'ba' will be used. Use equation (1) to calculate the amount of each phase as:

(g)

Interpretation:

The phases present, their compositions and their amounts for

Concept Introduction:

On the temperature-composition graph of an alloy, the curve above which the alloy exists in the liquid phase is the liquidus curve. The temperature at this curve is the maximum temperature at which the crystals in the alloy can coexist with its melt in the thermodynamic equilibrium.

Solidus curve is the locus of the temperature on the temperature composition graph of an alloy, beyond which the alloy is completely in a solid phase.

Between the solidus and liquidus curve, the alloy exits in a slurry form in which there is both crystals as well as alloy melt.

Solidus temperature is always less than or equal to the liquidus temperature.

Amount of each phase in wt% is calculated using lever rule. At a particular temperature and alloy composition, a tie line is drawn on the phase diagram of the alloy between the solidus and liquidus curve. Then the portion of the lever opposite to the phase whose amount is to be calculated is considered in the formula used as:

Answer to Problem 10.80P

Both solid, as well as liquid phases, are present at the given conditions.

Composition of the liquid phase present is

Composition of the solid phase present is

Amount of the liquid phase is

Amount of the solid phase is

Explanation of Solution

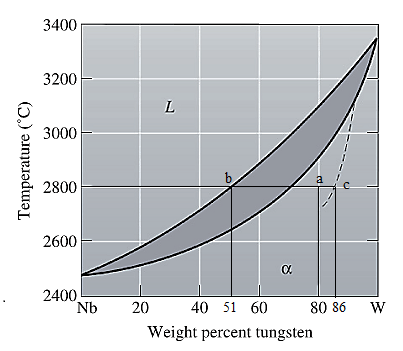

The equilibrium phase diagram for the Nb-W system is shown below as:

Now, draw a straight line from

Both the phases, solid and liquid are present at this non-equilibrium condition. Point 'b' represents the liquid phase composition in wt% and point 'c' represents the solid phase composition in wt% at non-equilibrium conditions. From the above phase diagram:

To calculate the amount of liquid phase, lever 'ac' will be used and to calculate the amount of solid phase, lever 'ba' will be used. Use equation (1) to calculate the amount of each phase as:

Want to see more full solutions like this?

Chapter 10 Solutions

ESS.MAT.SCI (LL W/MINDTAP)

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY