Interpretation:

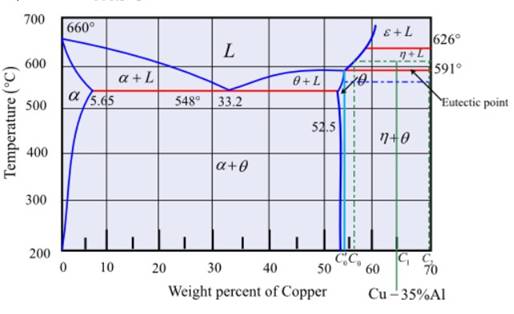

The amount of Aluminum required to be added and the liquid mixture cooled

diagram needs to be determined by referring to the given phase.

Concept introduction:

The aluminum alloy consists of aluminum as the parent material or the main constituent of the alloy. Aluminum alloy develops a white surface which acts as a protective layer of aluminum oxide.

Aluminum alloy has its major applications in the field of Aerospace industry as they are lighter, less flammable and have more strength.

Phase diagram is used to represent the

Answer to Problem 12.17P

The amount of aluminum to be added is calculated as

Explanation of Solution

Given Information:

Amount of aluminum

Weight percent of Cu-Al alloy

Calculation:

The composition of the Cu-Al alloy is Cu-

To calculate the temperature of the alloy, following expression is used,

Where, the alloy temperature=

The upper boundary temperature=

The lower boundary temperature=

Now, substituting the values as

Fig.

In the above-mentioned phase diagram, the Cu-

To calculate the weight percent of the alloy at temperature

Where,

Substituting the values as

To calculate the weight percentage of the mentioned alloy at the eutectic temperature

Where

Substituting the values as

Now, to calculate the amount of the aluminum to be added more, the following formula is used:

Where

Substituting the values as,

Putting the values,

To calculate the temperature change,

Where the values substituted are

Thus, based on the phase diagram of Cu-

Want to see more full solutions like this?

Chapter 12 Solutions

ESS.MAT.SCI (LL W/MINDTAP)

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY