Concept explainers

a)

To determine: The Economic order quantity.

Introduction: Inventory management is the process of ordering, storing and using inventory of the company such raw material, components and finished goods. It governs the flow of goods from manufacturers to warehouse and to the point of sale. The key function is to maintain record of flow of new or returned products which enters or leaves the company.

a)

Answer to Problem 28P

The economic order quantity for vendor A is 336.07 units and for vendor B is 335.08 units.

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Formula:

Where

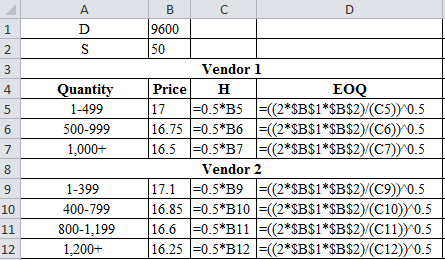

Calculation of Economic order quantity:

For vendor 1 with quantity 1-499:

EOQ is calculated by multiplying 2, 9600 and 50 and dividing the resultant

Same calculation procedure follows for the rest of the quantities and the result is,

| D | 9600 | ||

| S | $50.00 | ||

| Vendor 1 | |||

| Quantity | Price | H | EOQ |

| 1-499 | $17.00 | $8.50 | 336.07 |

| 500-999 | $16.75 | $8.38 | 338.57 |

| 1,000+ | $16.50 | $8.25 | 341.12 |

| Vendor 2 | |||

| 1-399 | $17.10 | $8.55 | 335.08 |

| 400-799 | $16.85 | $8.43 | 337.56 |

| 800-1,199 | $16.60 | $8.30 | 340.09 |

| 1,200+ | $16.25 | $8.13 | 343.74 |

Working:

Based on the above calculation, the EOQ for vendor A is 336.07 units and for vendor B is 335.08 units.

Hence, the economic order quantity for vendor A is 336.07 units and for vendor B is 335.08 units.

b)

To determine: The quantities to be ordered and supplier to be selected.

b)

Answer to Problem 28P

Vendor 2 should be selected at 1,200 units of ordering quantities

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Formula:

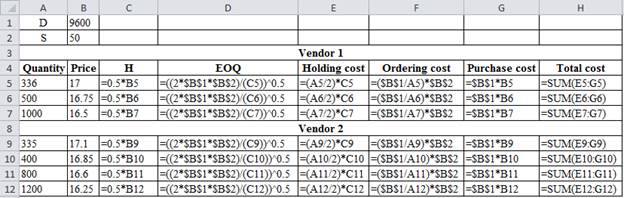

Calculation of ordering quantities:

| D | 9600 | ||||||

| S | $50.00 | ||||||

| Vendor 1 | |||||||

| Quantity | Price | H | EOQ | Holding cost | Ordering cost | Purchase cost | Total cost |

| 336 | $17.00 | $8.50 | 336.07 | $1,428.00 | $1428.6 | $163,200.00 | $166056.57 |

| 500 | $16.75 | $8.38 | 338.57 | $2,093.75 | $960.0 | $160,800.00 | $163853.75 |

| 1000 | $16.50 | $8.25 | 341.12 | $4,125.00 | $480.0 | $158,400.00 | $163005.00 |

| Vendor 2 | |||||||

| 335 | $17.10 | $8.55 | 335.08 | $1,432.13 | $1432.8 | $164,160.00 | $167024.96 |

| 400 | $16.85 | $8.43 | 337.56 | $1,685.00 | $1200.0 | $161,760.00 | $164645.00 |

| 800 | $16.60 | $8.30 | 340.09 | $3,320.00 | $600.0 | $159,360.00 | $163280.00 |

| 1200 | $16.25 | $8.13 | 343.74 | $4,875.00 | $400.0 | $156,000.00 | $161275.00 |

Table 1

Working:

Based on the above calculations it can be inferred that Vendor 2 can be selected because the total cost is least at 1,200 ordering quantities (refer table1).

Hence, vendor 2 should be selected at 1,200 units of ordering quantities.

c)

To determine: The total cost for most economic order quantities.

c)

Answer to Problem 28P

The optimum ordering quantity is 1200 units and total annual cost is $161275.00.

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Calculation of total cost:

Table 1 provides the calculation for total cost.

Hence, the optimum ordering quantity is 1200 units and total annual cost is $161275.00.

d)

To determine: The factors to be considered besides total cost.

d)

Explanation of Solution

Given information:

| Vendor 1 | |

| Quantity | Price |

| 1-499 | $17.00 |

| 500-999 | $16.75 |

| 1,000+ | $16.50 |

| Vendor 2 | |

| 1-399 | $17.10 |

| 400-799 | $16.85 |

| 800-1,199 | $16.60 |

| 1,200+ | $16.25 |

Factors to be considered besides total cost:

Apart from making decision based on total cost some other factor also have to be considered for making decisions to avoid uncertainty. Some other factors like perishability of the chemicals, the environment in which the chemicals are stored, storage space to handle 1,200 pounds of chemical have to be taken into account.

Want to see more full solutions like this?

Chapter 12 Solutions

Principles Of Operations Management

- BERNARDS COMPANY LTD is a PRODUCER of fruit juices. The company has an annual demand of 150,000 barrels. The barrels cost $30 each. Fresh supplies can be obtained immediately, but ordering cost and the cost of carriage inwards are $400 per order. The annual cost of holding one barrel in inventory is estimated to be $3.50. The economic order quantity has been calculated to be 10,500 barrels. The suppliers introduce a quantity discount of 5% on orders of at least 12,000 barrels and 5.5% on orders of at least 15,000 barrels. You are required to: Determine whether the least cost order quantity is still the EOQ of 10,500 barrels.arrow_forwardMiguel has a product with an annual holding cost percentage of 20%, an ordering cost of $110 per order, and annual demand of 15,000 units. The following price schedule applies to the product from a supplier. What is the optimal order quantity? Show all work including a graph. Units Price 1-250 $30.00 251-500 $28.00 501-750 $26.00 ≥ 751 $25.00arrow_forwardThe annual demand, ordering cost, and the annual inventory carrying cost rate for a certain item are 600 units, Quantity 1 to 49 50 to 249 250 and up Price $5.00/unit $4.50/unit $ 4.10/unit $20/order and 30% of item price, respectively. (a) Assume the discounts applied to all the units in the order, what should the order quantity be in order to minimize the average annual cost? Also, show the minimal average annual cost. (b) Assume the discounts applied to the units are incremental, what should the order quantity be in order to minimize the average annual cost? Also, show the minimal average annual cost.arrow_forward

- total inventory cost An auto parts supplier sells Hardy-brand batteries to car dealers and auto mechanics. The annual demand is approximately 1,200 batteries. The supplier pays $28 for each battery and estimates that the annual holding cost is 30 percent of the battery’s value. It costs approximately $20 to place an order (managerial and clerical costs). The supplier currently orders 100 batteries per month. a) Determine the ordering, holding, and total inventory costs for the current order quantity. b)Determine the ordering, holding, and total inventory costs for the EOQ. How has ordering cost changed? Holding cost? Total inventory cost?arrow_forwardABC Company purchased its inventory at a lump price of P20,000. Relative sales value for each type of inventory was: Inventory XX, P10,000 Inventory YY, P4,000 Inventory ZZ, P10,000 How much would be the cost assigned to inventory XX, YY an ZZ respectively? 10,000. 4,000 and 10,000 respectively 10,000, 4,000 and 8,333 respectively 8,333, 3,333 and 8333 respectively 6667, 6667 and 6667 respectivelyarrow_forwardA communication company is manufacturing mobile phones. Their annual demand is 5,000 mobile sets. They want to determine EOQ for a motherboard which has an annual holding cost (H) of $5/unit, and an ordering cost (S) of $60. They also want to calculate total cost (TC) and the reorder point (R) if the purchasing lead time is 4 days, assuming there are 300 working days per year. Find out: a. Economic Order quantity (EOQ) b. Total cost (TC) c. Reorder point (R)arrow_forward

- The annual demand for an item is 10,000 units. The cost to process an order is $75 and the annual inventory holding cost is 20% of item cost. What is the correct ordering policy (give optimal order quantity), given the following price breaks for purchasing the item? What price should the firm pay per unit? What is the total annual cost at the optimal behavior? Quantity: Price: 1-9 $2.95 per unit 10-999 $2.50 per unit 1,000-4,999 $2.30 per unit 5,000 or more $1.85 per unitarrow_forwardThe costs of placing an order are Rs. 150 per order. It is estimated that 1000 units will be used in the next 12 months. The carrying cost per month is Rs. 2.50. Assuming that the demand is deterministic and continuous and that no stock-outs are allowed, determine the optimal order quantity. 2. Based on the above, explain the following What is the time between the placing of orders? The procurement lead time is one month. What is the re-order point based on the on-hand inventory level?arrow_forwardThe Farmer’s Wife is a country store specializing in knickknacks suitable for a farm-house décor. One item experiencing a considerable buying frenzy is a miniature Holstein cow. Average weekly demand is 30 cows, with a standard deviation of 5 cows. The cost to place a replenishment order is $15 and the holding cost is $0.75/cow/year. The supplier, however, is inChina. The lead time for new orders is 8 weeks, with a standard deviation of 2 weeks. The Farmer’s Wife, which is open only 50 weeks a year, wants to develop a continuous review inventory system for this item with a cycle-service level of 90 percent.a. Specify the continuous review system for the cows. Explain how it would work in practice.b. What is the total annual cost for the system you developed?arrow_forward

- The sales of Whole Care mouthwash at Tom's of Maine over the past six months have averaged 2,000 cases per month, which is the current order quantity. Tom's of Maine's cost is $12.00 per case, and ordering cost is $38. The company estimates its cost of capital to be 12 percent. Insurance, taxes, breakage, handling, and pilferage are estimated to be approximately 6 percent of the item cost. Lead time is 3 days, and considering weekends and holidays, Tom's of Maine operates 250 days per year. Based on the above information please answer the following questions a) What is EOQ? b) What is the cost reduction? c) What is the reorder point? d) What is Time between Orders (TBO)?arrow_forwardAn auto parts supplier sells Hardy-brand batteries to car dealers and auto mechanics. The annual demand is approximately 1,200 batteries. The supplier pays $28 for each battery and estimates that the annual holding cost is 30 percent of the battery’s value. It costs approximately $20 to place an order (managerial and clerical costs). The supplier currently orders 100 batteries per month. a) Determine the ordering, holding, and total inventory costs for the current order quantity. b) Determine the economic order quantity(EOQ). c) How many orders will be placed per year using the EOQ? d) Determine the ordering, holding, and total inventory costs for the EOQ. How has ordering cost changed? Holding cost? Total inventory cost?arrow_forwardITEMS 14 and 15 ARE BASED ON THE FOLLOWING INFORMATION: The following information is available for Edgar Corporation's Material X Annual usage 12,600 units Working days per year 360 days Normal lead time 20 days The units of Material X are required evenly throughout the year. 14. What is the reorder point? a. 35 units c. 700 units b. 20th-day d. 630 units 15. Assuming that occasionally, the company experiences delay in the delivery of Material X, such that the lead time reaches a maximum of 30 days, how many units of safety stock should the company maintain and what is the reorder point? Safety Stock Reorder Point a. 350 1,050 b. 350 700 c. 0 1,050 d. 1,050…arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning