Concept explainers

What might Stephanie determine as the best production quantity per cycle for each day of the week?

To determine: The production sequence for cycle are S7, S8, S9, S1 and S2.

Introduction: A production cycle is a period through which the factors required by labors such as raw materials and goods stay in the creation process from the initial starting point of assembling through yield of finished goods.

Answer to Problem 1CQ

Explanation of Solution

Given Information:

| Model | Weekly Quantity |

| S1 | 120 |

| S2 | 102 |

| S7 | 48 |

| S8 | 90 |

| S9 | 25 |

The department operates five days a week. The production sequence is S7-S8-S9-S1-S2.

Calculate the daily demand for each model:

The demand for each model is calculated by dividing daily quantity of each model with total operational days.

Calculate the number of units per cycle for each model

It is calculated by dividing the daily demands with total operational days.

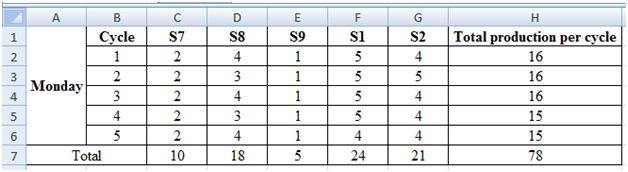

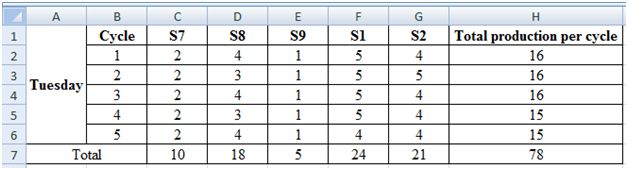

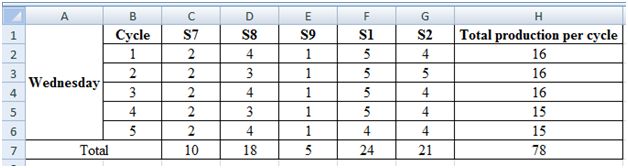

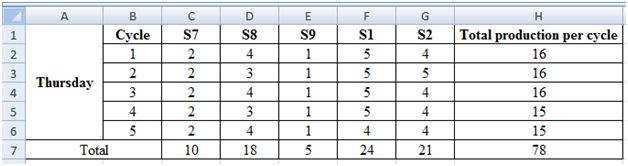

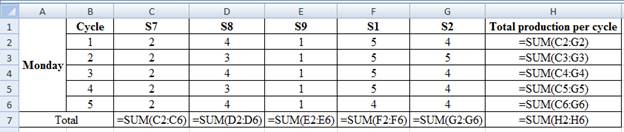

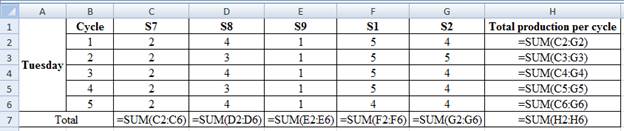

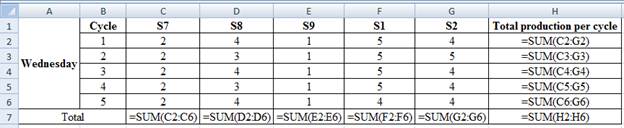

Calculate the production quantity per cycle for each day for 5 days from Monday to Friday.

This can be subjective. Production cycle should be on the sequence S7-S8-S9-S1-S2 done each cycle. We attempted to produce the same aggregate amount of units for every cycle. Whether this might have been not possible, we attempted with plan fewer units on the most last cycle of a day will consider getting up every day.

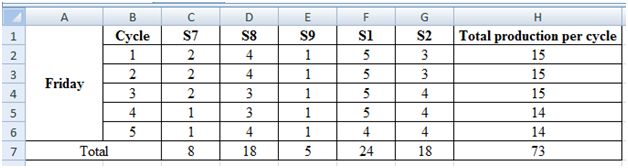

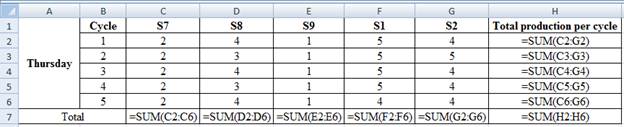

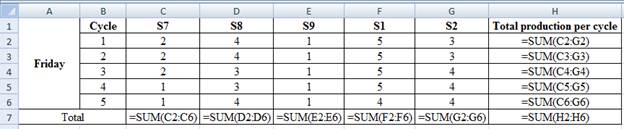

Excel Spreadsheet:

Calculate the production quantity per cycle for each model:

It is calculated by adding all the total values of each cycle from Monday to Friday.

Hence, the production sequence for cycle S7 is 48, S8 is 90, S9 is 25, S1 is 120 and S2 is 102.

Want to see more full solutions like this?

Chapter 14 Solutions

Operations Management

- What detail is required to build the aggregate schedule for an operations manager? List and illustrate the distinction between the capability options and the demand options for aggregate preparation. The approach or formula always provides the overall minimal cost for the overall plan?arrow_forwardAs the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 2 springs, and 4 clamps. The base is assembled from 2 clamps and 1 housing. Each clamp has 1handle and 1 casting. Each housing has 2 bearings and 2 shafts. There is no inventory on hand. Part 3 b) Determine the gross quantities needed of each item if you are to assemble 150 brackets. Base: enter your response here units (enter your response as a whole number). Spring: enter your response here units (enter your response as a whole number). Clamp: enter your response here units (enter your response as a whole number). Housing: enter your response here units (enter your response as a whole number). Handle: enter your response here units (enter your response as a whole number). Casting: enter your response here units (enter your response as a whole number). Bearing: enter…arrow_forwardThe following production data were taken from the records of the finishing department for June: Inventory in process, June 1, 25% completed 260 units Transferred to finished goods during June 5,000 units Equivalent units of production during June 5,495 units Determine the number of equivalent units of production in the June 30, finishing department inventory, assuming that the first-in, first-out method is used to cost inventories. The completion percentage of 25% applies to both direct materials and conversion costs. a.448 units b.840 units c.672 units d.560 unitsarrow_forward

- Given the following master production schedule require-ments and bill of labor, determine the work load in each work center for January. Given a 40-hour week and four weeks per month, how many workers would need to be as-signed to each work center to meet demand? Assume part-time workers are available.arrow_forwardJAYB, manager of a Fabrication company, has the following aggregate demand requirements and other data for the upcoming four quarters. Table 5: Forecast and cost information [Jadual 5: Maklumat Ramalan dan kos] Quarter [Suku] Demand [Permintaan] Previous quarter's output [Keluaran suku sebelumnya] 1,500 units 1 1,400 Beginning inventory [Inventori awal] 200 units 2 1,000 Hiring workers [Pengambilan pekerja] RM6 per unit 3 1,500 Laying off workers [Pembuangan pekerja] RM11 per unit 4 1,300 Unit cost [Kos unit] RM30 per unit With the information given, JAYB wants you to calculate the total cost of using chase strategy by hiring and layoff workers.arrow_forwardDAT, Inc., needs to develop an aggregate plan for its product line. Relevant data are Management prefers to keep a constant workforce and production level, absorbingvariations in demand through inventory excesses and shortages. Demand not met is carriedover to the following month.Develop an aggregate plan that will meet the demand and other conditions of theproblem. Do not try to i nd the optimum; just i nd a good solution and state the procedureyou might use to test for a better solution. Make any necessary assumptions.arrow_forward

- mafTech is a local companv assembles smart devices parts to various manutacturersproducing smartphones and computersLast year it had cost of goods sold of RM88.700 Million, the averageproduction materials and parts are RM1.333 Million, Work in progress atRM7.555 Million, and finished goods at RM5.999 Million. Define theaverage aggregate value, and Analyze the company's inventory turnsand days of supply being held in inventory.arrow_forwardDevelop a chase aggregate plan for Draper using apermanent workforce of 12 employees supplemented by overtime.All demand must be met each period.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.arrow_forwardExplain briefly what are the inputs to master scheduling and what are the outputs?arrow_forward

- Explain the different capacity based options used in aggregate planning and their implications for business ?arrow_forwardDescribe the following types of bills of material:a. Product tree.b. Multilevel bill.c. Single-level bill.d. Indented bill.e. Summarized parts list.f. Planning billarrow_forwardThe Walden Manufacturing Corp. has office support salaries of $4,000, factory supplies of $1,000,indirect labor of $6,000, direct materials of $16,000, advertising expense of $2,500, office expense of$14,000, and direct labor of $20,000. What is the total period cost?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.