(a)

Interpretation:

Value of Yield strength at

Concept introduction:

Elastic modulus is defined as the ratio of shear stress to shear strain. It is denoted by E, the relationship is given as,

Stress is defined as the ratio of load per unit area. It is denoted by

Where,

P is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

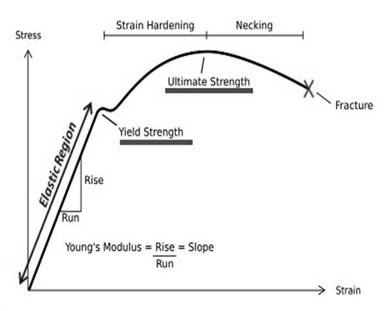

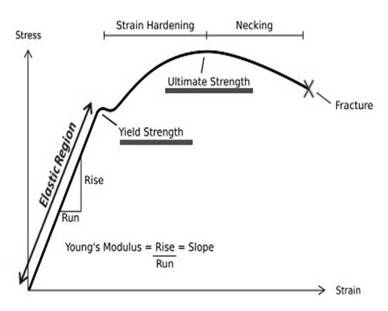

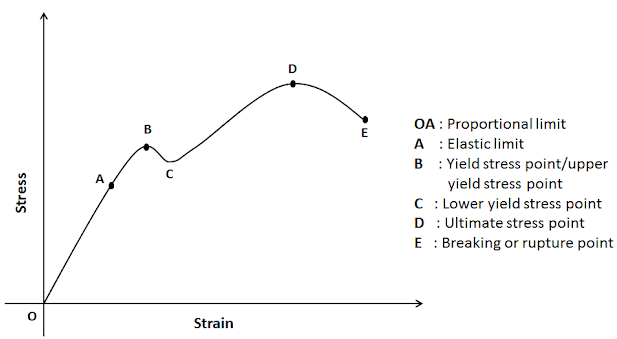

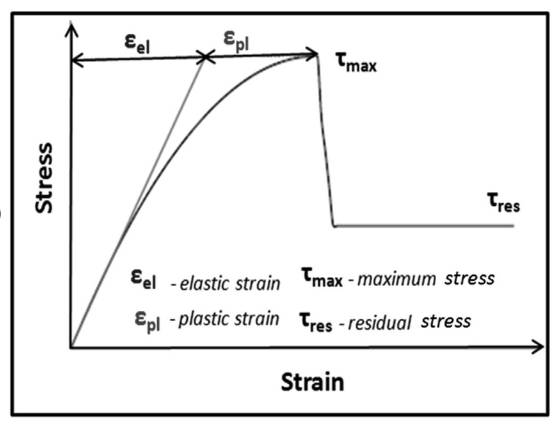

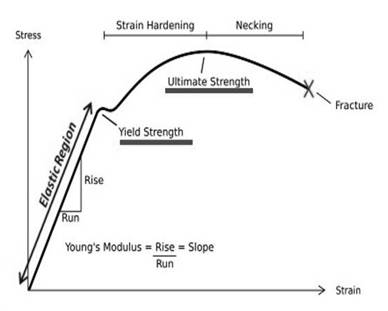

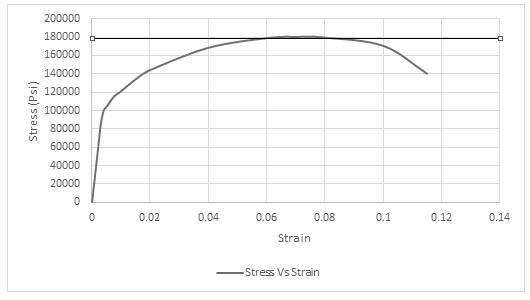

Offset is defined as the yield point in stress strain curve. The figure represents the Stress-Strain curve,

Answer to Problem 6.36P

The requiredvalue of Yield strength at

Explanation of Solution

Given information:

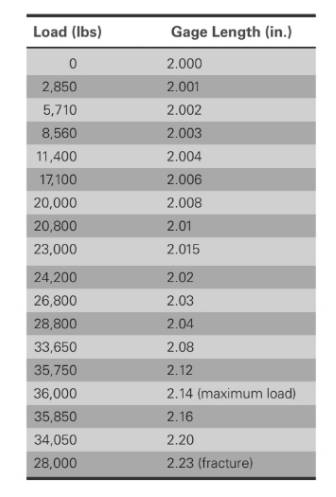

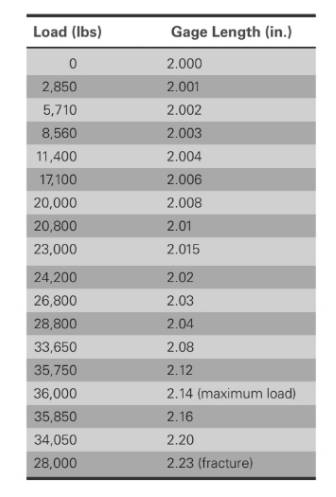

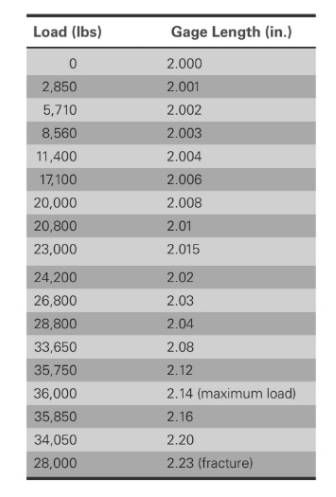

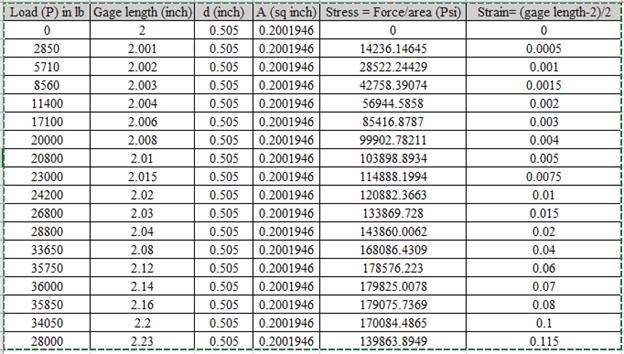

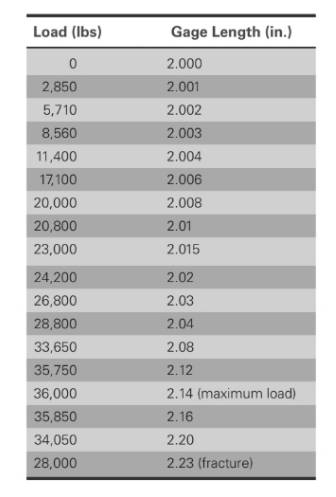

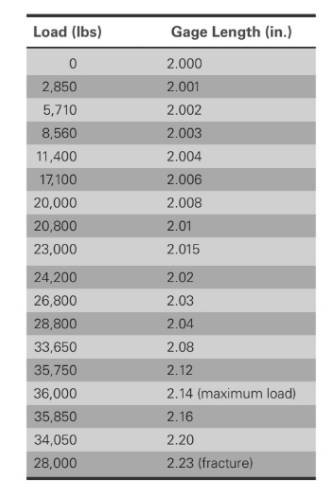

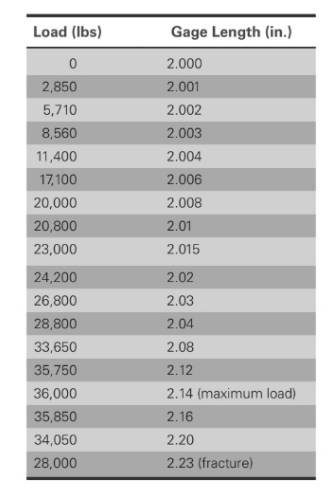

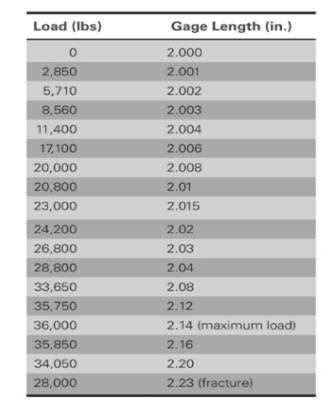

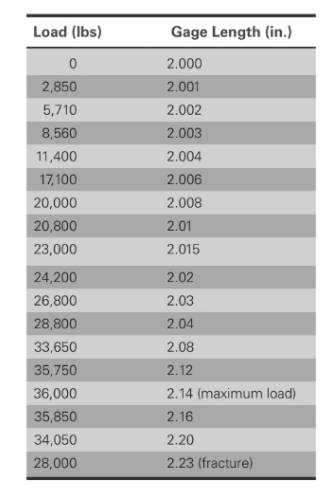

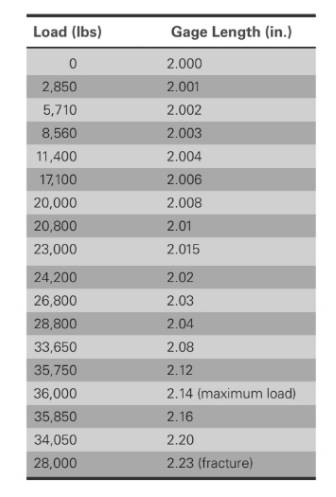

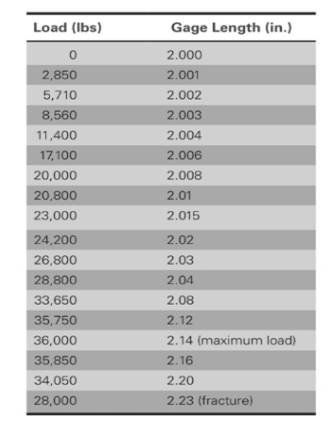

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

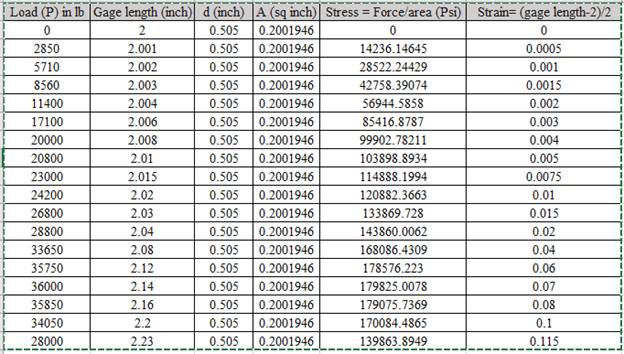

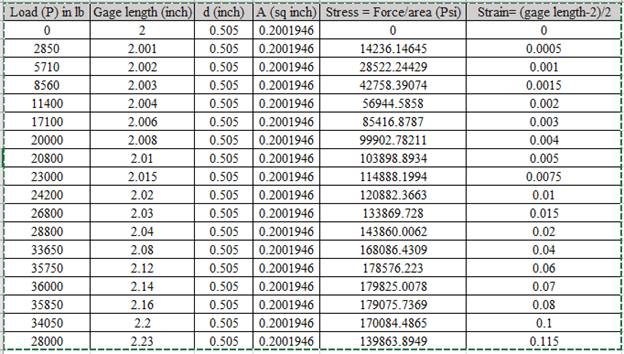

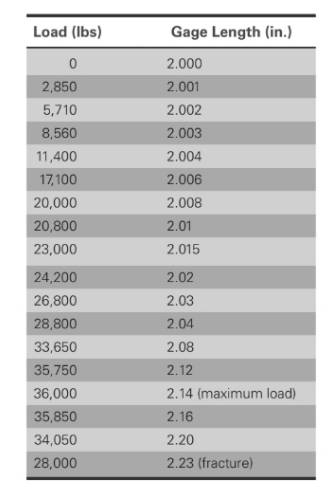

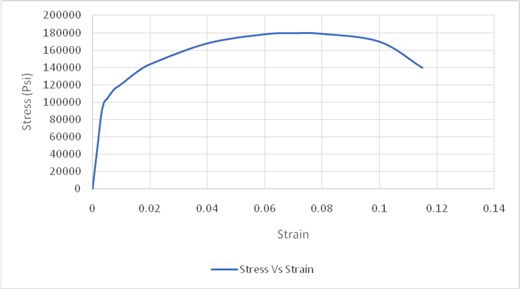

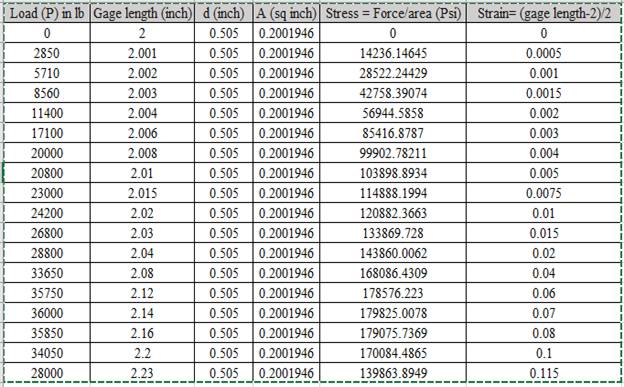

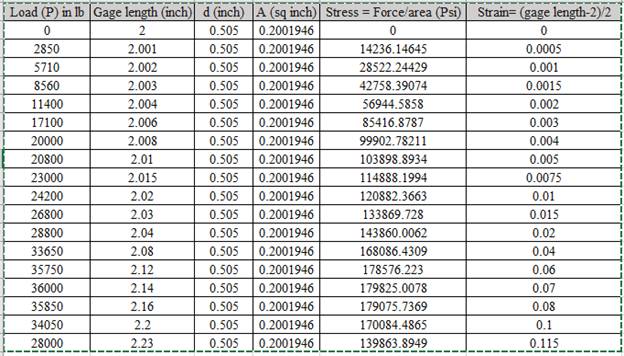

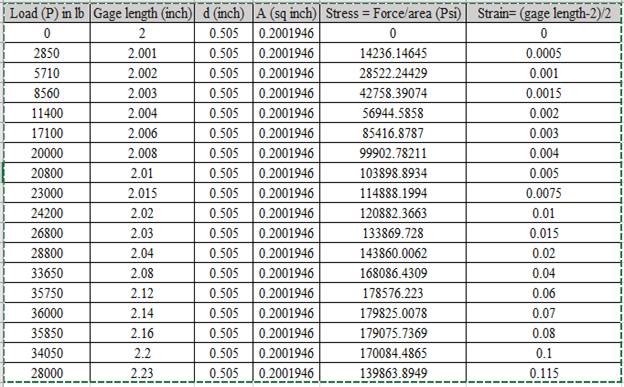

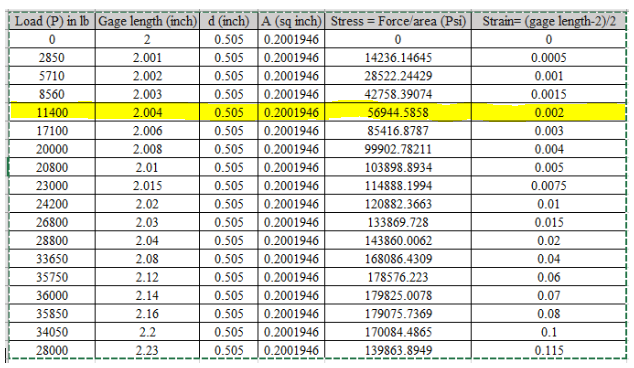

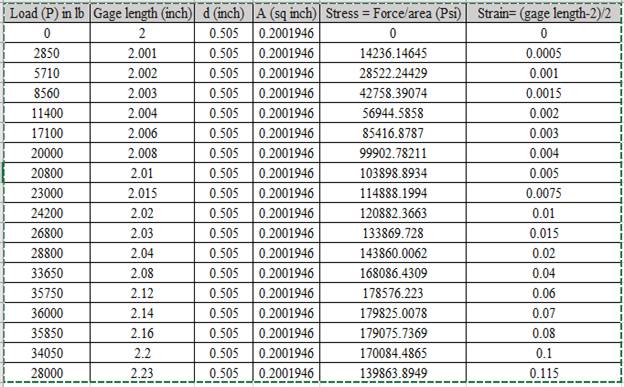

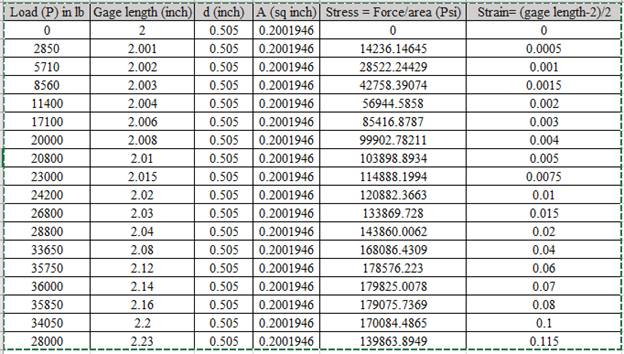

Calculation of stress and strain values are done using spreadsheet shown below,

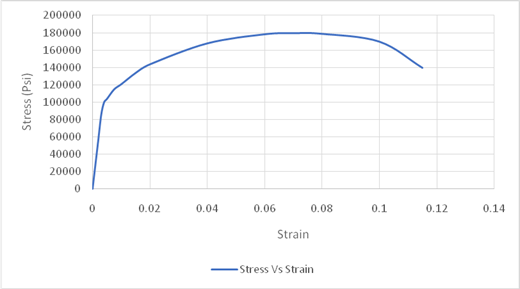

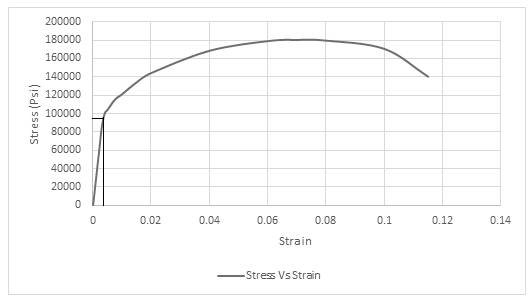

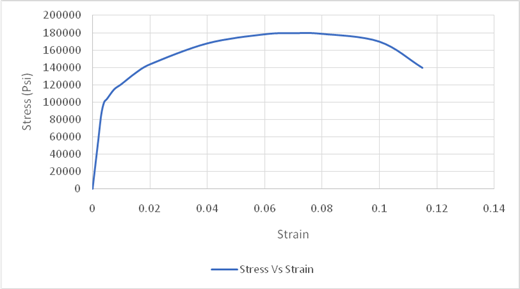

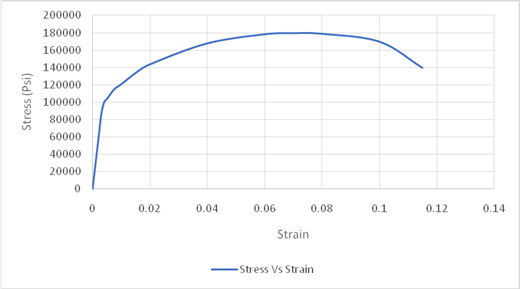

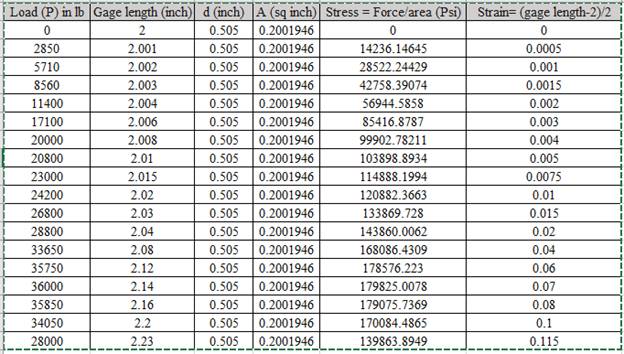

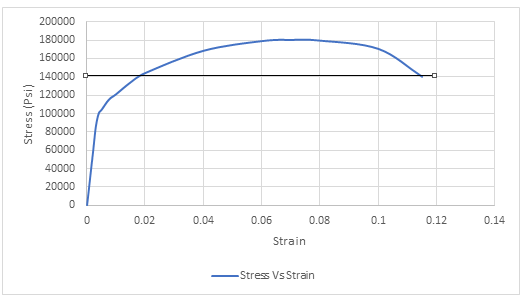

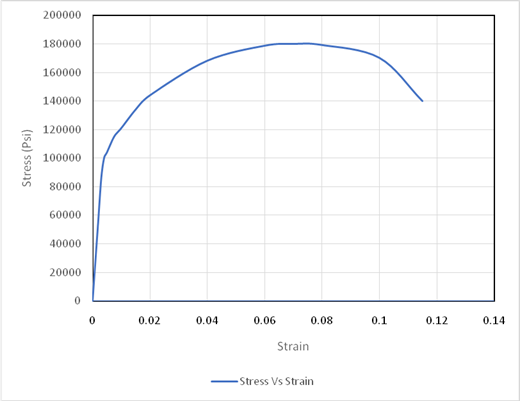

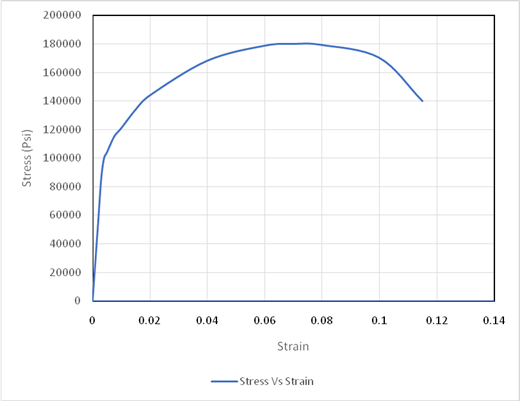

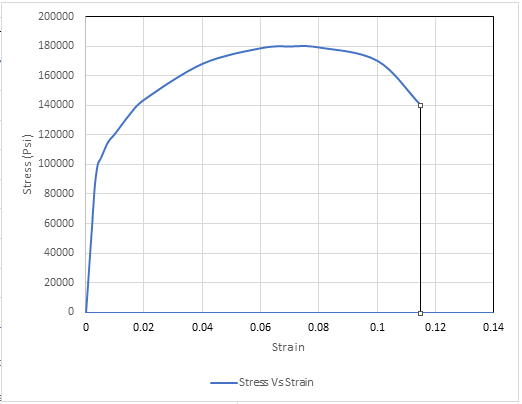

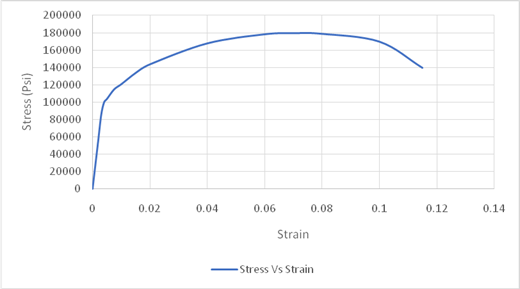

Using the data for Stress-Strain, Drawing the Stress Strain curve,

As, the value of offset is given in percentage so converting percentage by dividing it with

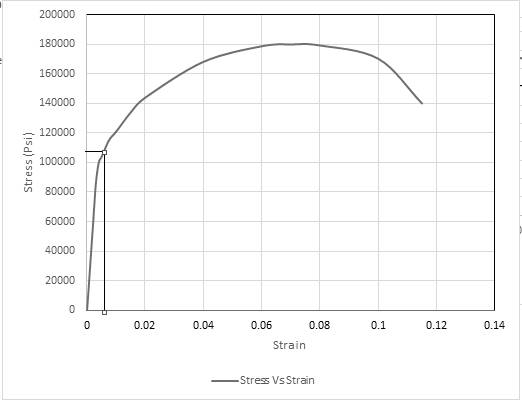

Drawing the tie line at offset of

Thus, the required value of yield strength is

(b)

Interpretation:

The value of tensile strength for the given condition is to be determined.

Concept introduction:

Elastic modulus is defined as the ratio of shear stress to shear strain. It is denoted by E, the relationship is given as,

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

Tensile strength is the maximum load that material can withstand without rapture. The above graph is reflecting relationship between stress and strain.

Answer to Problem 6.36P

Thus, the required value of tensile strength is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

Calculation of stress and strain values are done using spreadsheet shown below,

Using the data for Stress-Strain, Drawing the Stress Strain curve,

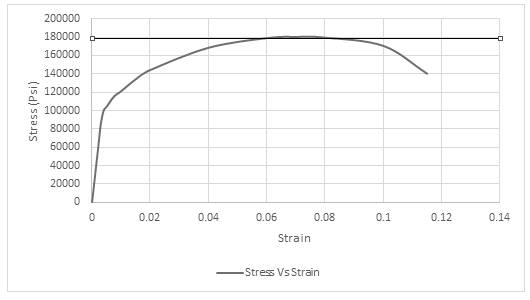

The maximum value of stress is used for obtaining the value of tensile strength. Drawing tie lines as shown in the figure below,

Thus, the required value of tensile strength is

(c)

Interpretation:

The value of Modulus of elasticity for the given condition should be calculated.

Concept introduction:

Elastic modulus is defined as the ratio of shear stress to shear strain. It is denoted by E, the relationship is given as,

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

The graph of Proportionality constant using modulus of elasticity,

Answer to Problem 6.36P

Thus, the required value of modulus of elasticity is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

Calculation of stress and strain values are done using spreadsheet shown below,

Using the data for Stress-Strain, Drawing the Stress Strain curve,

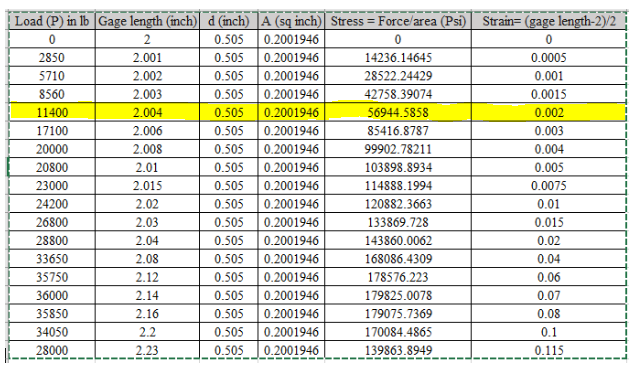

For calculating the modulus of elasticity, the values considered are highlighted in spreadsheet,

Using the above table the value of stress is

Calculation of modulus of elasticity,

Putting the values in formula,

Thus, the required value of modulus of elasticity is

(d)

Interpretation:

The value of percentage elongation for the given condition should be calculated.

Concept introduction:

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

Percentage elongation:

It is defined as the ratio of difference between final length and initial length to initial length. The relationship is given as,

Where,

Answer to Problem 6.36P

Thus, the required value of percentage elongation is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the values,

Gage length before fracture is

Gage length after fracture is

Putting the values in the formula of percentage elongation,

Thus, the required value of percentage elongation is

(e)

Interpretation:

The value of percentage reduction in area for given condition should be calculated.

Concept introduction:

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

True Strain: It is defined as the ratio of gage length to instantaneous gage length. The formula is given below:

Where,

Percentage Reduction in Area:

It is defined as the ratio of difference between final length and initial length to initial length. The relationship is given as,

Where,

Answer to Problem 6.36P

The required value of percentage reduction in area is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the given values,

Calculation of

Calculation of

Substituting the values in the formula of percentage reduction of area,

The required value of percentage reduction in area is

(f)

Interpretation:

The value of engineering stress at fracture should be determined.

Concept introduction:

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

Answer to Problem 6.36P

Thus, the required value of Stress at fracture is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the given values,

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

Calculation of stress and strain values are done using spreadsheet shown below,

Using the data for Stress-Strain, Drawing the Stress Strain curve,

Drawing the tie lie at the fracture point of Stress-Strain curve,

Thus, the required value of Stress at fracture is

(g)

Interpretation:

The value of true stress at necking should be calculated.

Concept introduction:

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

True stress is defined as the ratio of force per unit area. The relationship is given as,

Where,

Answer to Problem 6.36P

Thus, the required value of true stress at neck point is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the given values,

The different values of stress, Strain, gage diameter is shown below:

Calculation of true stress:

Following points are considered for calculating the values of true stress at gage length of

Calculation of area,

Calculation of strain,

Putting the values in the formula of true stress,

Thus, the required value of true stress at neck point is

(h)

Interpretation:

The value of Modulus of resilience for the given condition should be calculated.

Concept introduction:

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

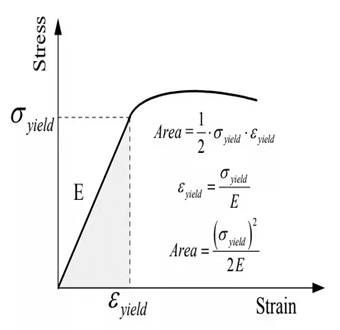

Modulus of Resilience is defined as the maximum amount of energy that a material can withstand without creating the permanent distortion of the material.

The relationship of Modulus of Resilience is,

Where,

The graph is showing the values of yield stress and strain corresponding to the yield value,

Answer to Problem 6.36P

Thus, the required value of modulus of resilience is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the given values,

The different values of stress, Strain, gage diameter is shown below:

Based on the calculated values of stress and strain. The graph is shown below,

Using the above graph drawing tie lines,

Thus, based on the tie line, The value for yield stress is

Substituting the values for calculating the modulus of resilience,

Thus, the required value of modulus of resilience is

(i)

Interpretation:

The value of elastic and plastic strain corresponding to fracture should be determined.

Concept introduction:

Elastic strainis defined as the distortion in the structure.

Plastic Strain is defined as the permanent distortion of structure.

The graph for elastic and plastic strain is shown below:

Answer to Problem 6.36P

Thus, the required value of elastic strain is

Thus, the required value of plastic strain is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Based on the given values,

The different values of stress, Strain, gage diameter is shown below:

Based on the given values.

Plotting the graph,

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

For calculating the modulus of elasticity, the values considered are highlighted in spreadsheet,

Using the above table the value of stress is

Putting the value of modulus of elasticity and stress,

Calculation of elastic strain,

Putting the values in formula,

Thus, the required value of elastic strain is

Using graph, drawing tie lines for determining the value of plastic strain,

Thus, the required value of plastic strain is

(j)

Interpretation:

The transverse and axial strain for given condition should be determined. Also, the value of Poisson's ratio is to be calculated.

Concept introduction:

Transverse Strain is defined as the ratio of change in diameter to original diameter. The relationship is given as,

Where,

d is the original diameter.

Axial Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

Poisson's Ratio:

It is defined as the ratio of transverse strain to axial strain represented as:

Answer to Problem 6.36P

The required value of transverse strain is

Thus, the required value of axial strain is

The required value of Poisson's ratio is

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Load for sample is

Diameter of sample is

Based on the given values,

The different values of stress, Strain, gage diameter is shown below:

Calculation of transverse strain,

Where,

Putting the values,

The required value of transverse strain is

Calculation of axial strain,

Where,

Thus, the required value of axial strain is

Calculation of Poisson's ratio,

Putting the value of transverse and axial strain,

Thus, the required value of Poisson's ratio is

(k)

Interpretation:

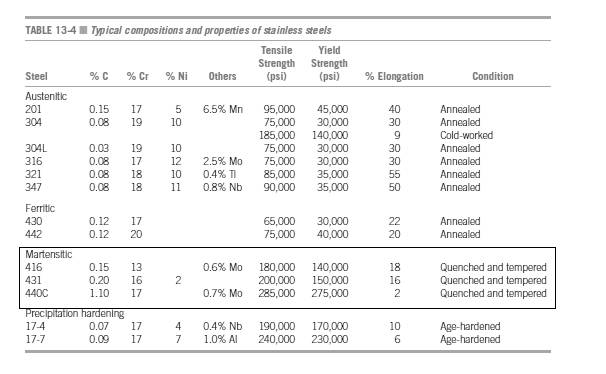

The value of tensile strength for 416 stainless steel is to be determined. Also, the comparison of values for tensile strength should be explained.

Concept introduction:

Elastic modulus is defined as the ratio of shear stress to shear strain. It is denoted by E, the relationship is given as,

Stress is defined as the ratio of force per unit area. It is denoted by

Where,

F is the force in newton.

A is area in square meter.

Strain is defined as the ratio of change in length to original length. It is denoted by

Where,

Strain is dimensionless quantity.

Tensile strength is the maximum load that material can withstand without rapture. The above graph is reflecting relationship between stress and strain.

Answer to Problem 6.36P

Thus, the required calculated value of tensile strength is

Thus, the value of tensile strength remains the same after quenching and tempering.

Explanation of Solution

Given information:

The data for AISI-SAE stainless steel is given below:

Diameter of stainless steel is

Gage length before fracture is

After fracture, the given values are,

Gage length after fracture is

Diameter of stainless steel is

The values of load correspond to gage length is shown in table,

Load for sample is

Diameter of sample is

Based on given information

Applying formula of elastic modulus,

Stress is calculated on the basis on force and area. The given formula is,

Calculation of stress and strain values are done using spreadsheet shown below,

Using the data for Stress-Strain, Drawing the Stress Strain curve,

The maximum value of stress is used for obtaining the value of tensile strength. Drawing tie lines as shown in the figure below,

Thus, the required value of tensile strength is

Based on the given information the physical and mechanical properties of 416 stainless steel is shown below:

Thus, the required calculated value of tensile strength is

Thus, the required calculated value of yield strength is

The values of 416 stainless steel when quenched and tempered is shown in table,

Thus, the value of tensile strength remains the same after quenching and tempering.

Want to see more full solutions like this?

Chapter 6 Solutions

ESS.MAT.SCI (LL W/MINDTAP)

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY