Concept explainers

Twelve tasks, with times and precedence requirements as shown in the following table, are 10 be assigned to workstations using a cycle time of 1.5 minutes. Two heuristic rules will be tried: (1) greatest positional weight, and (2) most following tasks. In each case, the tiebreaker will be shortest processing time.

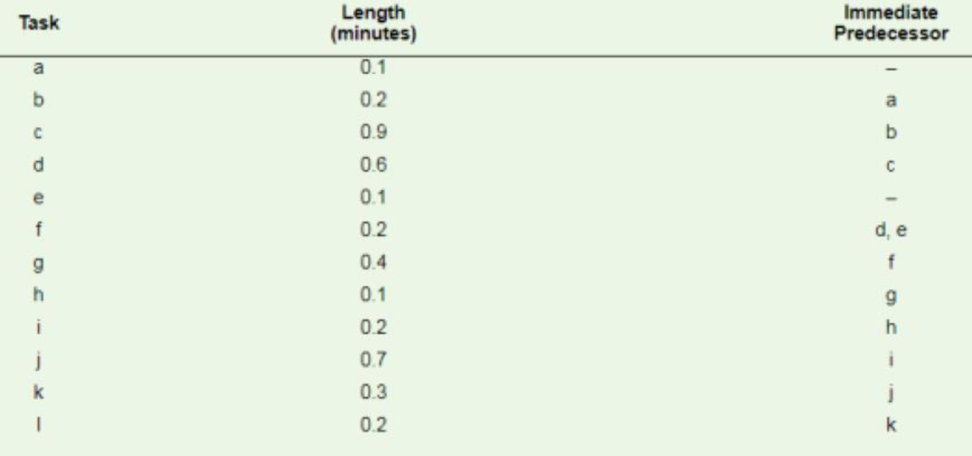

a. Draw the precedence diagram for this line.

b. Assign tasks to stations under each of the two rules.

c. Compute the percentage of idle tune fox each rule.

a)

To draw: The precedence diagram.

Answer to Problem 6P

Precedence diagram:

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

Precedence diagram:

The precedence diagram is drawn circles and arrows. The tasks are represented in circles and weights for each task are represented outside the circle. The arrows are represented to show which task is preceding the other task and so on.

b)

1)

To assign: Tasks on the basis of greatest positional weight.

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

The number of following tasks, calculation of positional weight, processing time for each task is shown below.

| Task | Following tasks | Number of following tasks | Calculation of positional weight | Positional weight | Processing time |

| a | b, c, d, f, g, h, i, j, k, l | 10 | 0.1 + 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.9 | 0.1 |

| b | c, d, f, g, h, i, j, k, l | 9 | 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.8 | 0.2 |

| c | d, f, g, h, i, j, k, l | 8 | 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.6 | 0.9 |

| d | f, g, h, i, j, k, l | 7 | 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.7 | 0.6 |

| e | f, g, h, i, j, k, l | 7 | 0.1 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.2 | 0.1 |

| f | g, h, i, j, k, l | 6 | 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.1 | 0.2 |

| g | h, i, j, k, l | 5 | 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.9 | 0.4 |

| h | i, j, k, l | 4 | 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.5 | 0.1 |

| i | j, k, l | 3 | 0.2 + 0.7+ 0.3 + 0.2 | 1.4 | 0.2 |

| j | k, l | 2 | 0.7+ 0.3 + 0.2 | 1.2 | 0.7 |

| k | l | 1 | 0.3 + 0.2 | 0.5 | 0.3 |

| l | Nil | 0 | 0.2 | 0.2 | 0.2 |

Assigning tasks to workstations:

| Workstation number | Eligible task | Assigned task | Task time | Unassigned cycle time | Reason |

| 1.5 | |||||

| 1 | a, e | a | 0.1 | 1.4 | Task 'a' has highest positional weight |

| b, e | b | 0.2 | 1.2 | Task 'b' has highest positional weight | |

| c, e | c | 0.9 | 0.3 | Task 'c' has highest positional weight | |

| d, e | e | 0.1 | 0.2 | Task 'e' is the only eligible task available | |

| d | None | 0.2 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 1.5 | |||||

| 2 | d | d | 0.6 | 0.9 | Task 'd' is the only eligible task available |

| f | f | 0.2 | 0.7 | Task 'f' is the only eligible task available | |

| g | g | 0.4 | 0.3 | Task 'g' is the only eligible task available | |

| h | h | 0.1 | 0.2 | Task 'h' is the only eligible task available | |

| i | i | 0.2 | 0 | Task 'i' is the only eligible task available | |

| 1.5 | |||||

| 3 | j | j | 0.7 | 0.8 | Task 'j' is the only eligible task available |

| k | k | 0.3 | 0.5 | Task 'k' is the only eligible task available | |

| l | l | 0.2 | 0.3 | Task 'l' is the only eligible task available | |

| 0.3 (Idle time) | All tasks completed |

Overview of tasks assignment:

| Workstation | Assigned tasks | Total cycle time used | Idle time |

| 1 | a, b, c, e | 1.3 | 0.2 |

| 2 | d, f, g, h, i | 1.5 | 0 |

| 3 | j, k, l | 1.2 | 0.3 |

2)

To assign: Tasks on the basis of most following tasks.

Explanation of Solution

Given information:

| Task | Duration (minutes) | Immediate (Predecessor) |

| a | 0.1 | Nil |

| b | 0.2 | a |

| c | 0.9 | b |

| d | 0.6 | c |

| e | 0.1 | Nil |

| f | 0.2 | d, e |

| g | 0.4 | f |

| h | 0.1 | g |

| i | 0.2 | h |

| j | 0.7 | i |

| k | 0.3 | j |

| l | 0.2 | k |

Cycle time = 1.5 minutes

The number of following tasks, calculation of positional weight, processing time for each task is shown below.

| Task | Following tasks | Number of following tasks | Calculation of positional weight | Positional weight | Processing time |

| a | b, c, d, f, g, h, i, j, k, l | 10 | 0.1 + 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.9 | 0.1 |

| b | c, d, f, g, h, i, j, k, l | 9 | 0.2 + 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.8 | 0.2 |

| c | d, f, g, h, i, j, k, l | 8 | 0.9 + 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 3.6 | 0.9 |

| d | f, g, h, i, j, k, l | 7 | 0.6 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.7 | 0.6 |

| e | f, g, h, i, j, k, l | 7 | 0.1 + 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.2 | 0.1 |

| f | g, h, i, j, k, l | 6 | 0.2 + 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 2.1 | 0.2 |

| g | h, i, j, k, l | 5 | 0.4 + 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.9 | 0.4 |

| h | i, j, k, l | 4 | 0.1 + 0.2 + 0.7+ 0.3 + 0.2 | 1.5 | 0.1 |

| i | j, k, l | 3 | 0.2 + 0.7+ 0.3 + 0.2 | 1.4 | 0.2 |

| j | k, l | 2 | 0.7+ 0.3 + 0.2 | 1.2 | 0.7 |

| k | l | 1 | 0.3 + 0.2 | 0.5 | 0.3 |

| l | Nil | 0 | 0.2 | 0.2 | 0.2 |

Assigning tasks to workstations:

| Workstation number | Eligible task | Assigned task | Task time | Unassigned cycle time | Reason |

| 1.5 | |||||

| 1 | a, e | a | 0.1 | 1.4 | Task 'a' has the most following tasks |

| b, e | b | 0.2 | 1.2 | Task 'b' has the most following tasks | |

| c, e | c | 0.9 | 0.3 | Task 'c' has the most following tasks | |

| d, e | e | 0.1 | 0.2 | Task 'e' is the only eligible task available | |

| d | None | 0.2 (Idle time) | The task time is greater than the unassigned cycle time. | ||

| 1.5 | |||||

| 2 | d | d | 0.6 | 0.9 | Task 'd' is the only eligible task available |

| f | f | 0.2 | 0.7 | Task 'f' is the only eligible task available | |

| g | g | 0.4 | 0.3 | Task 'g' is the only eligible task available | |

| h | h | 0.1 | 0.2 | Task 'h' is the only eligible task available | |

| i | i | 0.2 | 0 | Task 'i' is the only eligible task available | |

| 1.5 | |||||

| 3 | j | j | 0.7 | 0.8 | Task 'j' is the only eligible task available |

| k | k | 0.3 | 0.5 | Task 'k' is the only eligible task available | |

| l | l | 0.2 | 0.3 | Task 'l' is the only eligible task available | |

| 0.3 (Idle time) | All tasks completed |

Overview of tasks assignment:

| Workstation | Assigned tasks | Total cycle time used | Idle time |

| 1 | a, b, c, e | 1.3 | 0.2 |

| 2 | d, f, g, h, i | 1.5 | 0 |

| 3 | j, k, l | 1.2 | 0.3 |

c)

To determine: The percentage of idle time.

Answer to Problem 6P

Explanation of Solution

Formula to calculate percentage of idle time:

Calculation of percentage of idle time:

The solutions for most following tasks rule and highest positional weight is same. Hence, the percentage of idle time will also be the same.

The percentage of idle time is 11.11%.

Want to see more full solutions like this?

Chapter 6 Solutions

OPERATIONS MANAGEMENT (LL) >CUSTOM<

- As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly operation to achieve an output of 230 units per 8-hour day. Task times and precedence relationships are as follows: Task Duration(minutes) ImmediatePredecessor a 0.2 - b 0.6 a c 0.4 b d 0.7 - e 1.6 d f 1.8 c g 2 e, farrow_forwardThe tasks shown in the following precedence diagram are to be assigned to workstations with theintent of minimizing idle time. Management has designed an output rate of 275 units per day. Assume440 minutes are available per day.a. Determine the appropriate cycle time.b. What is the minimum number of stations possible?arrow_forwardA manufacturer is designing a product layout for a new product productionIt plans to use a production line for 8 hours per day in order to meet forecasted demand of 70 units per day. The product requires 7 tasks in total. These tasks are namelyABC, D, E, F, and Grespectively. Task A does not have any predecessor to startTo start Task B.it requires Task A to be completedStarting tasks needs, the task B to be completed. Also, starting task Dneeded task B to be completed. Task E can only start upon completion of Task C. Whereas starting task F needs the completion of both the tasks D and E. Finally, starting task G needed task Fto be completed. The processing times for tasks, ABC, D. E. and G are 2.8, 2.1, 0.9, 1.0, 1.2, 1.8 and 4.7 minutes respectively. What should be the cycle time in minutes? a 4.7 b. None is the correct answer Oc 7.5 d6.86 e.arrow_forward

- A local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed . The daily demand is 120 toys. Times of the tasks are 2.73,2.01 1, 2.13, 2.0, 2.61, 2.71 , and 2.95 minutes for A ,B,C,D,E,F, , and G, respectively . However, due to the nature of product there are precedence rules that must be observed . Such that Task A does not need any predecessors ; task B requires task be completed. To start task C and task D, each require task B to be completed . Task C must be completed prior to stating task E. Task F needs both task D and task Eto be completed . Finally, task G can start only once task F is completed . What is the minimum number of workstations needed? a. 4 b. 5 c. 6 d. None of them e. 8arrow_forwardA shoe repair operation uses a two-step sequence that all jobs in a certain category follow. Alljobs can be split in half at both stations. For the group of jobs listed:a. Find the sequence that will minimize total completion time.b. Determine the amount of idle time for workstation B.c. What jobs are candidates for splitting? Why? If they were split, how much would idle time andmakespan time be reduced?JOB TIMES (minutes)A B C D EWorkstation A 27 18 70 26 15Workstation B 45 33 30 24 10arrow_forwardGiven this list of tasks, how much idle time is at station 3 if the cycle time is 15 minutes and the Longest Operation Time heuristic is used? Task Duration (min) Predecessor A 8 -- B 7 A C 9 B D 6 C E 7 C F 7 D,E G 9 F H 12 G ANSWER Unselected 3 minutes Unselected 2 minutes Unselected 1 minute Unselected I DON'T KNOW YETarrow_forward

- A producer of inkjet printers is planning to add a new line of printers, and you have been asked to balance the process, given the following task times and precedence relationships. Assume that cycle time is to be the minimum possible. Task Length(minutes) Immediate(Predecessor) a 0.2 - b 0.4 a c 0.3 - d 1.3 b, c e 0.1 - f 0.8 e g 0.3 d, f h 1.2 g Click here for the Excel Data File a. Do each of the following: (1) Enter the number of following tasks for each of the tasks shown in the table below. (2) Assign tasks to stations in order of greatest number of following tasks. Use greatest positional weight as a tiebreaker rule. (3) Determine the percentage of idle time. (Round your answer to 2 decimal places.) (4) Compute the rate of output in printers per day that could be expected for this line, assuming a 420-minute working day. (Round your answer 2 decimal places.) b. Answer these questions: (1) What is the…arrow_forwardA manutacturer is designing a product layout for a new product production. It plans to use a production line for B hours per day in order to meet forecasted demand of 100 units per day. The product requires 7 lasks in total. These tasks are namely, A, 8, CD, E, F, and G respectively. Task A does not have any predecessor to start. To start Task B, it requires Task A to be completed Starting tasks Cneeds, the tack B to be completed. Also, starting task D needed task B to be completed Task E can only start upon completion of Task C. Whescas starting lask F needs the completion of both the tasks D and E Finally, starting task G needed, task Fto be completed. 1the processing times for tasks, A BC D, E F, andG are 28, 2.1, 0.9, 1.0, 1.2, 1.8, are 4.7 minutes respectively. Applying the most following tasks nule for balancing the assembly line, with ties broken according to longest task time first, the tasks that will be assigned to the FIRST workstation are Select one OaAB, and C ODAB Oc None…arrow_forwardUdesign is a plant producing mass production dresses. The following table shows the tasks needed to be preformed, their task times and proceeding tasks. It is required to produce 30 dresses per hour. Task Immediate predecessor Task time (sec) A - 30 B - 40 C - 20 D A 100 E B,D 25 F C,D 50 G D,E,F 50 H G 90 a- Compute the cycle time and minimum number of workstations required b- Draw the precedence diagram c- What is the maximum output for this line d- Assign tasks to workstations using most number of followers e- Compute efficiency of such linearrow_forward

- Develop a solution for the following line balancing problem, allowing a cycle time of 5 minutes. Draw the precedence diagram for the set of tasks. Calculate the minimum number of workstations. Show what tasks are assigned to which stations? Using the heuristic rules How much idle time is there, summed over all workstations? What is the efficiency of this line? Work Task Task Time (seconds) Immediate Predecessor(s) A 70 - B 60 A C 120 B D 60 - E 240 C, D F 100 A G 190 E, Farrow_forwardA local bakery makes custom cakes for special eventssuch as weddings and graduations. Making cakes is a two-step process of baking and decorating. The bakery has received eight orders, and the times required in hours for baking and decorating for each order are given in the following table:Cake Orders Baking DecoratingA 3 4B 1 2C 4 7D 2 4E 5 10F 2 6G 5 7H 6 13Determine a sequence that will minimize the makespan time.Construct a chart of the resulting sequence, and determine the idle time in te decoration process.arrow_forwardThe Mowry Machine Shop still has five jobs to be processedas of 8 a.m. today (day 23) at its bottleneck operation. The daywhen the order arrived, processing time, and promised duedates are given in the following table. The jobs are listed inthe order of arrival.a. Develop separate schedules by using the FCFS and EDDrules. Compare the schedules on the basis of averageflow time and average days past due.b. Which rule gives the best schedule, in your judgment?Why?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.