2.18 Perform a degrees of freedom analysis for the model in Eqs. 2-64 through 2-68. Identify parameters, output variables, and inputs (manipulated and disturbance variables). tions in the inlet Mixture of A and B mics of the pro- omatic control is 9, CA, T V, p, T 2.4 Dyna reaction. In other words, the heat of mixing is neg- ligible compared to the heat of reaction. 8. Shaft work and heat losses to the ambient can be neglected. decrease in lelllllld displayed in centration as The following form of the CSTR energy balance is convenient for analysis and can be derived from Eqs. 2-62 and 2-63 and Assumptions 1-8 (Fogler, 2006; Russell and Denn, 1972), TR) have wide- embody many STR models tend types of continu- and packed-bed odel provides a ing principles for Table 2.3 Nc Cooling medium at temperature T. Parameter VpcdT = wC(T; - T) + (-AHR)Vkc, Figure 2.6 A nonisothermal continuous stirred-tank reactor. dt + UA(T. – T) (2-68) For these assumptions, the unsteady-state mass balance { for the CSTR is where AHR is the heat of reaction per mole of A that is reacted. In summary, the dynamic model of the CSTR consists of Eqs. 2-62 to 2-64, 2-66, 2-67, and 2-68. This model is nonlinear as a result of the many product terms and Tne exponential temperature dependence of k in Eq. 2-63. Consequently, it must be solved by numerical integra- tion techniques (Fogler, 2006). The CSTR model will become considerably more complex if -AHR versible chemical ets to form species B. We assume that d(pV) (2-64) = pq, - pg dt Because V and p are constant, Eq. 2-64 reduces to 450 respect to compo- (2-65) q = 9i Thus, even though the inlet and outlet flow rates may change due to upstream or downstream conditions, Eq. 2-65 must be satisfied at all times. In Fig. 2.6, both flow rates are denoted by the symbol q. For the stated assumptions, the unsteady-state com- ponent balances for species A (in molar concentration units) is (2-62) e 400- 1. More complicated rate expressions are considered. For example, a mass action kinetics model for a second-order, irreversible reaction, 2A B, is given by per unit volume, units of reciprocal tion of species A. onstant is typically ature given by the 1 = kzc 350 ---. (2-69) 2. Additional species or chemical reactions are involved. If the reaction mechanism involved pro- duction of an intermediate species, 2A B → B, then unsteady-state component balances for both A and B* would be necessary (to calculate c, and CR), or balances for both A and B could be written (to calculate c, and cB). Information concerning the reaction mechanisms would also be required. y dea = q(CAi - CA) – VkcA (2-66) 300 dt (2-63) This balance is a special case of the general component balance in Eq. 2-7. Next, balance for the CSTR. But first we make five additional Figure 2.7 Rea. changes in cool and from 300 to E is the activation The expressions in theoretical consid- and E are usually consider an unsteady-state energy we Reactions involving multiple species are described by high-order, highly coupled, nonlinear reaction models, because several component balances must be written. assumptions: 1.0 4. The thermal capacitances of the coolant and the cooling coil wall are negligible compared to the thermal capacitance of the liquid in the tank. 5. All of the coolant is at a uniform temperature, T- (That is, the increase in coolant temperature as the coolant passes through the coil is neglected.) 0.9 data. Thus, these obe semi-empirical in Section 2.2. CSTR is shown in 0.8 EXAMPLE 2.5 0.7 To illustrate how the CSTR can exhibit nonlinear dynamic behavior, we simulate the effect of a step change in the coolant temperature T, in positive and negative directions. Table 2.3 shows the parameters and nominal operating condition for the CSTR based on Eqs. 2-66 and 2-68 for the exothermic, irreversible first-order reaction A two state variables of the ODES are the concentration of A (c.) and the reactor temperature T. The manipulated input variable is the jacket water temperature, T Two cases are simulated, one based on increased cool- ing by changing T, from 300 to 290 K and one reducing the cooling rate by increasing T, from 300 to 305 K. These model equations are solved in MATLAB with a numerical integrator (ode15s) over a 10-min horizon. The 0.6 of pure component cooling coil is used t the desired oper- cat that is released 0.5 0.4 6. The rate of heat transfer from the reactor contents to the coolant is given by 0.3 0.2- 0.1 B. The nitial CSTR model (2-67) Q = UA(T- T) mptions: where U is the overall heat transfer coefficient and A is the heat transfer area. Both of these model parameters are assumed to be constant. 7. The enthalpy change associated with the mixing of the feed and the liquid in the tank is negligible com- pared with the enthalpy change for the chemical 0. Figure 2.8 React. changes in coolin and product streams are denoted by p. ctor is kept constant Reactant A concentration (mol/L) Reactor temperature (K):

2.18 Perform a degrees of freedom analysis for the model in Eqs. 2-64 through 2-68. Identify parameters, output variables, and inputs (manipulated and disturbance variables). tions in the inlet Mixture of A and B mics of the pro- omatic control is 9, CA, T V, p, T 2.4 Dyna reaction. In other words, the heat of mixing is neg- ligible compared to the heat of reaction. 8. Shaft work and heat losses to the ambient can be neglected. decrease in lelllllld displayed in centration as The following form of the CSTR energy balance is convenient for analysis and can be derived from Eqs. 2-62 and 2-63 and Assumptions 1-8 (Fogler, 2006; Russell and Denn, 1972), TR) have wide- embody many STR models tend types of continu- and packed-bed odel provides a ing principles for Table 2.3 Nc Cooling medium at temperature T. Parameter VpcdT = wC(T; - T) + (-AHR)Vkc, Figure 2.6 A nonisothermal continuous stirred-tank reactor. dt + UA(T. – T) (2-68) For these assumptions, the unsteady-state mass balance { for the CSTR is where AHR is the heat of reaction per mole of A that is reacted. In summary, the dynamic model of the CSTR consists of Eqs. 2-62 to 2-64, 2-66, 2-67, and 2-68. This model is nonlinear as a result of the many product terms and Tne exponential temperature dependence of k in Eq. 2-63. Consequently, it must be solved by numerical integra- tion techniques (Fogler, 2006). The CSTR model will become considerably more complex if -AHR versible chemical ets to form species B. We assume that d(pV) (2-64) = pq, - pg dt Because V and p are constant, Eq. 2-64 reduces to 450 respect to compo- (2-65) q = 9i Thus, even though the inlet and outlet flow rates may change due to upstream or downstream conditions, Eq. 2-65 must be satisfied at all times. In Fig. 2.6, both flow rates are denoted by the symbol q. For the stated assumptions, the unsteady-state com- ponent balances for species A (in molar concentration units) is (2-62) e 400- 1. More complicated rate expressions are considered. For example, a mass action kinetics model for a second-order, irreversible reaction, 2A B, is given by per unit volume, units of reciprocal tion of species A. onstant is typically ature given by the 1 = kzc 350 ---. (2-69) 2. Additional species or chemical reactions are involved. If the reaction mechanism involved pro- duction of an intermediate species, 2A B → B, then unsteady-state component balances for both A and B* would be necessary (to calculate c, and CR), or balances for both A and B could be written (to calculate c, and cB). Information concerning the reaction mechanisms would also be required. y dea = q(CAi - CA) – VkcA (2-66) 300 dt (2-63) This balance is a special case of the general component balance in Eq. 2-7. Next, balance for the CSTR. But first we make five additional Figure 2.7 Rea. changes in cool and from 300 to E is the activation The expressions in theoretical consid- and E are usually consider an unsteady-state energy we Reactions involving multiple species are described by high-order, highly coupled, nonlinear reaction models, because several component balances must be written. assumptions: 1.0 4. The thermal capacitances of the coolant and the cooling coil wall are negligible compared to the thermal capacitance of the liquid in the tank. 5. All of the coolant is at a uniform temperature, T- (That is, the increase in coolant temperature as the coolant passes through the coil is neglected.) 0.9 data. Thus, these obe semi-empirical in Section 2.2. CSTR is shown in 0.8 EXAMPLE 2.5 0.7 To illustrate how the CSTR can exhibit nonlinear dynamic behavior, we simulate the effect of a step change in the coolant temperature T, in positive and negative directions. Table 2.3 shows the parameters and nominal operating condition for the CSTR based on Eqs. 2-66 and 2-68 for the exothermic, irreversible first-order reaction A two state variables of the ODES are the concentration of A (c.) and the reactor temperature T. The manipulated input variable is the jacket water temperature, T Two cases are simulated, one based on increased cool- ing by changing T, from 300 to 290 K and one reducing the cooling rate by increasing T, from 300 to 305 K. These model equations are solved in MATLAB with a numerical integrator (ode15s) over a 10-min horizon. The 0.6 of pure component cooling coil is used t the desired oper- cat that is released 0.5 0.4 6. The rate of heat transfer from the reactor contents to the coolant is given by 0.3 0.2- 0.1 B. The nitial CSTR model (2-67) Q = UA(T- T) mptions: where U is the overall heat transfer coefficient and A is the heat transfer area. Both of these model parameters are assumed to be constant. 7. The enthalpy change associated with the mixing of the feed and the liquid in the tank is negligible com- pared with the enthalpy change for the chemical 0. Figure 2.8 React. changes in coolin and product streams are denoted by p. ctor is kept constant Reactant A concentration (mol/L) Reactor temperature (K):

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

Transcribed Image Text:2.18 Perform a degrees of freedom analysis for the model in

Eqs. 2-64 through 2-68. Identify parameters, output variables,

and inputs (manipulated and disturbance variables).

Transcribed Image Text:tions in the inlet

Mixture of A and B

mics of the pro-

omatic control is

9, CA, T

V, p, T

2.4 Dyna

reaction. In other words, the heat of mixing is neg-

ligible compared to the heat of reaction.

8. Shaft work and heat losses to the ambient can be

neglected.

decrease in

lelllllld

displayed in

centration as

The following form of the CSTR energy balance

is convenient for analysis and can be derived from

Eqs. 2-62 and 2-63 and Assumptions 1-8 (Fogler, 2006;

Russell and Denn, 1972),

TR) have wide-

embody many

STR models tend

types of continu-

and packed-bed

odel provides a

ing principles for

Table 2.3 Nc

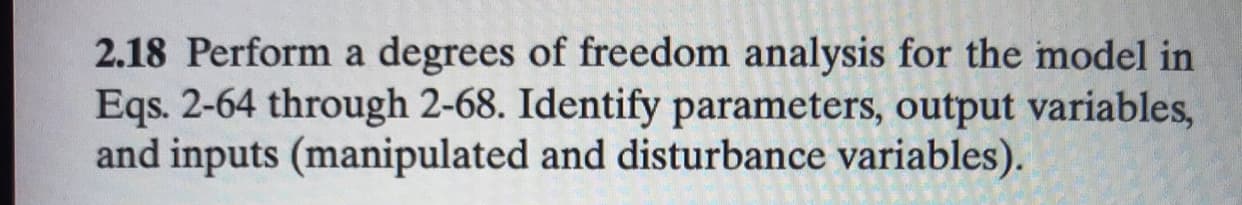

Cooling medium

at temperature

T.

Parameter

VpcdT

= wC(T; - T) + (-AHR)Vkc,

Figure 2.6 A nonisothermal continuous stirred-tank reactor.

dt

+ UA(T. – T)

(2-68)

For these assumptions, the unsteady-state mass balance {

for the CSTR is

where AHR is the heat of reaction per mole of A that is

reacted.

In summary, the dynamic model of the CSTR consists

of Eqs. 2-62 to 2-64, 2-66, 2-67, and 2-68. This model is

nonlinear as a result of the many product terms and Tne

exponential temperature dependence of k in Eq. 2-63.

Consequently, it must be solved by numerical integra-

tion techniques (Fogler, 2006). The CSTR model will

become considerably more complex if

-AHR

versible chemical

ets to form species

B. We assume that

d(pV)

(2-64)

= pq, - pg

dt

Because V and p are constant, Eq. 2-64 reduces to

450

respect to compo-

(2-65)

q = 9i

Thus, even though the inlet and outlet flow rates may

change due to upstream or downstream conditions,

Eq. 2-65 must be satisfied at all times. In Fig. 2.6, both

flow rates are denoted by the symbol q.

For the stated assumptions, the unsteady-state com-

ponent balances for species A (in molar concentration

units) is

(2-62)

e 400-

1. More complicated rate expressions are considered.

For example, a mass action kinetics model for a

second-order, irreversible reaction, 2A B, is

given by

per unit volume,

units of reciprocal

tion of species A.

onstant is typically

ature given by the

1 = kzc

350 ---.

(2-69)

2. Additional species or chemical reactions are

involved. If the reaction mechanism involved pro-

duction of an intermediate species, 2A B → B,

then unsteady-state component balances for both

A and B* would be necessary (to calculate c, and

CR), or balances for both A and B could be written

(to calculate c, and cB). Information concerning

the reaction mechanisms would also be required.

y dea

= q(CAi - CA) – VkcA

(2-66)

300

dt

(2-63)

This balance is a special case of the general component

balance in Eq. 2-7.

Next,

balance for the CSTR. But first we make five additional

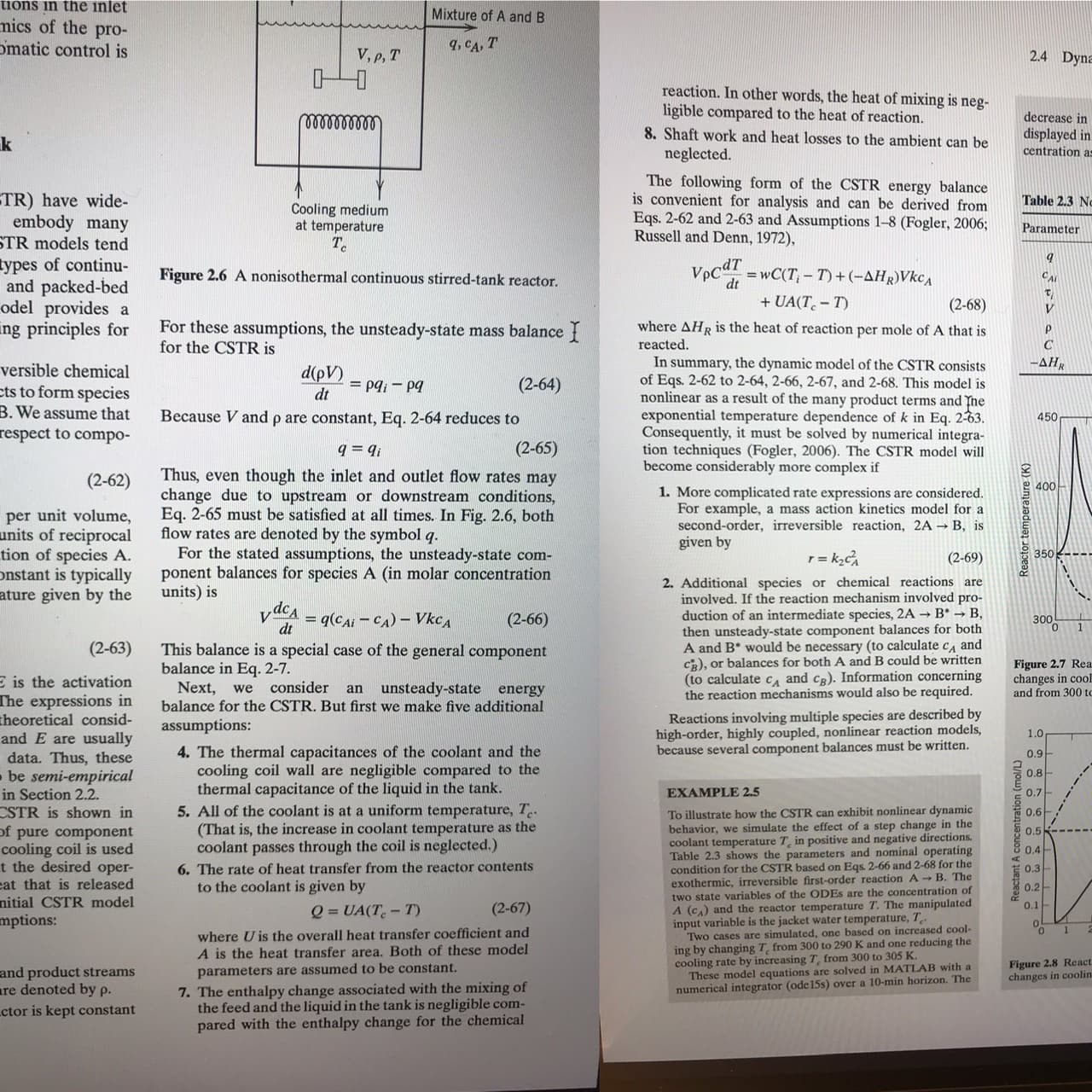

Figure 2.7 Rea.

changes in cool

and from 300 to

E is the activation

The expressions in

theoretical consid-

and E are usually

consider

an unsteady-state energy

we

Reactions involving multiple species are described by

high-order, highly coupled, nonlinear reaction models,

because several component balances must be written.

assumptions:

1.0

4. The thermal capacitances of the coolant and the

cooling coil wall are negligible compared to the

thermal capacitance of the liquid in the tank.

5. All of the coolant is at a uniform temperature, T-

(That is, the increase in coolant temperature as the

coolant passes through the coil is neglected.)

0.9

data. Thus, these

obe semi-empirical

in Section 2.2.

CSTR is shown in

0.8

EXAMPLE 2.5

0.7

To illustrate how the CSTR can exhibit nonlinear dynamic

behavior, we simulate the effect of a step change in the

coolant temperature T, in positive and negative directions.

Table 2.3 shows the parameters and nominal operating

condition for the CSTR based on Eqs. 2-66 and 2-68 for the

exothermic, irreversible first-order reaction A

two state variables of the ODES are the concentration of

A (c.) and the reactor temperature T. The manipulated

input variable is the jacket water temperature, T

Two cases are simulated, one based on increased cool-

ing by changing T, from 300 to 290 K and one reducing the

cooling rate by increasing T, from 300 to 305 K.

These model equations are solved in MATLAB with a

numerical integrator (ode15s) over a 10-min horizon. The

0.6

of pure component

cooling coil is used

t the desired oper-

cat that is released

0.5

0.4

6. The rate of heat transfer from the reactor contents

to the coolant is given by

0.3

0.2-

0.1

B. The

nitial CSTR model

(2-67)

Q = UA(T- T)

mptions:

where U is the overall heat transfer coefficient and

A is the heat transfer area. Both of these model

parameters are assumed to be constant.

7. The enthalpy change associated with the mixing of

the feed and the liquid in the tank is negligible com-

pared with the enthalpy change for the chemical

0.

Figure 2.8 React.

changes in coolin

and product streams

are denoted by p.

ctor is kept constant

Reactant A concentration (mol/L)

Reactor temperature (K):

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 7 steps with 12 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The