Problem 8: The following load elongation data were recorded during the tensile testing of a copper bar measuring 0.505 in. (0.0128 m) in diameter, with a gauge length of 2 in. (0.0508 m). d. What is the percentage elongation at fracture? e. Calculate true stress-true strain values up to onset of necking.

Problem 8: The following load elongation data were recorded during the tensile testing of a copper bar measuring 0.505 in. (0.0128 m) in diameter, with a gauge length of 2 in. (0.0508 m). d. What is the percentage elongation at fracture? e. Calculate true stress-true strain values up to onset of necking.

Materials Science And Engineering Properties

1st Edition

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Charles Gilmore

Chapter6: Introduction To Mechanical Properties

Section: Chapter Questions

Problem 6.2P

Related questions

Question

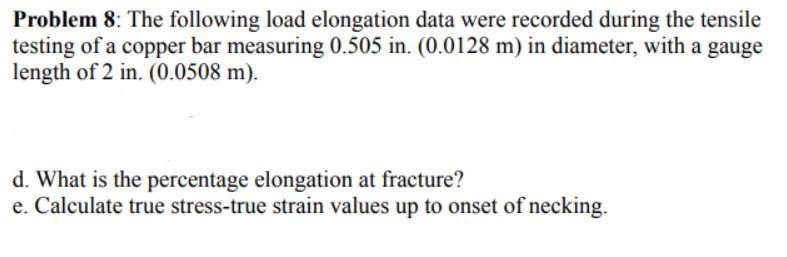

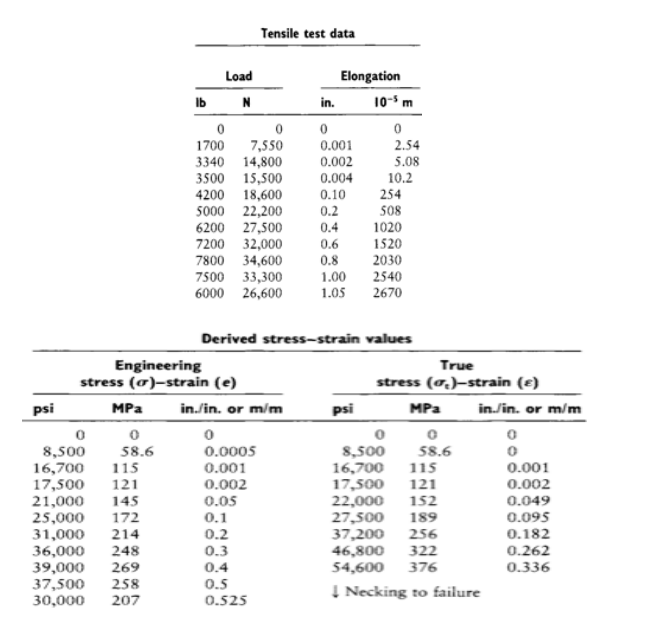

Transcribed Image Text:Problem 8: The following load elongation data were recorded during the tensile

testing of a copper bar measuring 0.505 in. (0.0128 m) in diameter, with a gauge

length of 2 in. (0.0508 m).

d. What is the percentage elongation at fracture?

e. Calculate true stress-true strain values up to onset of necking.

Transcribed Image Text:Tensile test data

Load

Elongation

Ib N

in.

10- m

7,550

3340 14,800

3500 15,500

4200 18,600

2.54

5.08

10.2

1700

0.001

0.002

0.004

0.10

254

5000 22,200

6200 27,500

7200 32,000

7800 34,600

7500 33,300

6000 26,600

0.2

508

1020

1520

0.4

0.6

0.8

2030

1.00

2540

1.05

2670

Derived stress-strain values

True

Engineering

stress (o)-strain (e)

stress (7,)-strain (e)

psi

MPa

in./in. or m/m

psi

MPa

in./in. or m/m

8,500

16,700

17,500

21,000

25,000

31,000

36,000

39,000

37,500

30,000

58.6

0.0005

0.001

8,500

16,700

17,500

22,000

27,500

37,200

46,800

54,600

58.6

115

115

0.001

121

0.002

121

0.002

152

145

172

0.05

0.049

0.1

0.2

189

256

322

0.095

214

248

0.182

0.262

0.3

269

258

0.4

376

0.336

0.5

0.525

I Necking to failure

207

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Materials Science And Engineering Properties

Civil Engineering

ISBN:

9781111988609

Author:

Charles Gilmore

Publisher:

Cengage Learning

Steel Design (Activate Learning with these NEW ti…

Civil Engineering

ISBN:

9781337094740

Author:

Segui, William T.

Publisher:

Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:

9781111988609

Author:

Charles Gilmore

Publisher:

Cengage Learning

Steel Design (Activate Learning with these NEW ti…

Civil Engineering

ISBN:

9781337094740

Author:

Segui, William T.

Publisher:

Cengage Learning