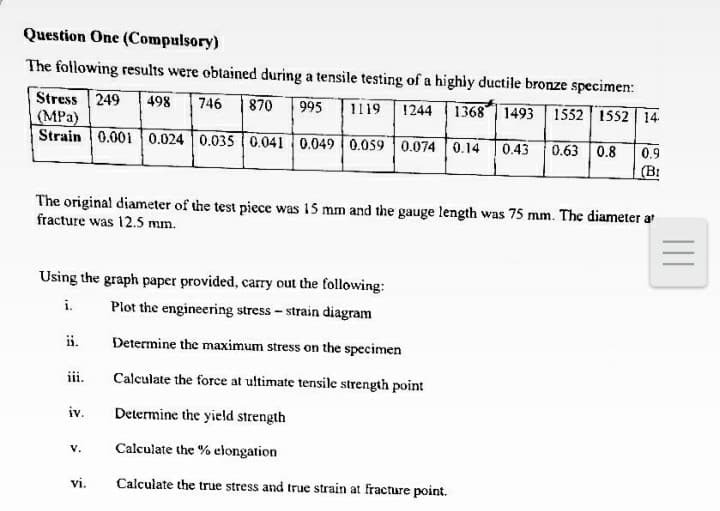

Question One (Compulsory) The following results were obtained during a tensile testing of a highiy ductile bronze specimen: Stress 249 (MPa) Strain 0.001 0.024 0.035 0.041 0.049 0.059 0.074 0.14 498 746 870 995 1119 1244 1368 1493 1552 1552 | 14. 0.43 0.63 0.8 0.9 (B! The original diameter of the test piece was 15 mm and the gauge length was 75 mm. The diameter at fracture was 12.5 mm. Using the graph paper provided, carry out the following: i. Plot the engineering stress - strain diagram ii. Determine the maximum stress on the specimen iii. Calculate the force at ultimate tensile strength point

Question One (Compulsory) The following results were obtained during a tensile testing of a highiy ductile bronze specimen: Stress 249 (MPa) Strain 0.001 0.024 0.035 0.041 0.049 0.059 0.074 0.14 498 746 870 995 1119 1244 1368 1493 1552 1552 | 14. 0.43 0.63 0.8 0.9 (B! The original diameter of the test piece was 15 mm and the gauge length was 75 mm. The diameter at fracture was 12.5 mm. Using the graph paper provided, carry out the following: i. Plot the engineering stress - strain diagram ii. Determine the maximum stress on the specimen iii. Calculate the force at ultimate tensile strength point

Steel Design (Activate Learning with these NEW titles from Engineering!)

6th Edition

ISBN:9781337094740

Author:Segui, William T.

Publisher:Segui, William T.

Chapter1: Introduction

Section: Chapter Questions

Problem 1.5.5P: The results of a tensile test are shown in Table 1.5.2. The test was performed on a metal specimen...

Related questions

Question

Transcribed Image Text:Question One (Compulsory)

The following results were obtained during a tensile testing of a highiy ductile bronze specimen:

Stress 249

(MPa)

Strain 0.001 0.024 0.035 0.041 0.049 0.059 0.074 0.14

498

746

870

995 1119 1244

1368 1493 1552 1552 14

0.43

0.63 0.8

0.9

(B:

The original diameter of the test piece was 15 mm and the gauge length was 75 mm. The diameter a

fracture was 12.5 mm.

Using the graph paper provided, carry out the following:

i.

Plot the engineering stress - strain diagram

ii.

Determine the maximum stress on the specimen

ii.

Calculate the force at ultimate tensile strength point

iv.

Determine the yield strength

Calculate the % elongation

V.

vi.

Calculate the true stress and true strain at fracture point.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 1 images

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti…

Civil Engineering

ISBN:

9781337094740

Author:

Segui, William T.

Publisher:

Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:

9781111988609

Author:

Charles Gilmore

Publisher:

Cengage Learning

Steel Design (Activate Learning with these NEW ti…

Civil Engineering

ISBN:

9781337094740

Author:

Segui, William T.

Publisher:

Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:

9781111988609

Author:

Charles Gilmore

Publisher:

Cengage Learning