Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

May I know the solution for this question with full answer. Help me please. Thankyou so much

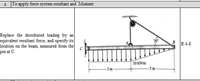

Transcribed Image Text:To apply force system resultant and Moment

Replace the distributed loading by an

equivalent resultant force, and specify its

location on the beam, measured from the

pin at C

R 4-8

10 kN/m

3m

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- a. What is the ideal mechanical advantage of this system? The inclined plane dimensions are 7.2 meters length and 1.8 meters height.b. What effort force is required to move the 600N create? c. In practice, you need to supply an effort force of 75 N to lift the crate. What is the efficiency?d. How could you redesign this compound machine so that the effort force needed was 50 N in practice? Assume the efficiency is your response from part C no matter what changes you make. Be specific with the changes you propose (if you add pulleys state how many, if you change the inclined plane dimensions state the new dimensions, etc.).arrow_forwardWe have a rectangular piece. We wish to manufacture a parallel slot along thepiece in a vertical milling machine and 50 cm from the edge. The width of the slot is 40 mm. TheDepth of the slot is 25 mm. For this, several rough cutting steps and aFine cut with a depth of 0.20 mm. The depth for each of the steps ofrough cut is limited to 1.75 mmAditional information:What is the number of blades used for the rough cutting steps?What is the number of blades used for the fine cutting step?arrow_forwardAvalanche coin e. Key opportunities, risks and challenges. Using the information in the whitepaper as well as other resources available today, identify and discuss the 4-5 key factors that you believe are most likely to impact the success or failure of the project.arrow_forward

- With the help of an example, explain open, closed, and isolated systems.arrow_forwardAt Axiom Space you work with other astronautical engineers to combine your mechanical and creative talents and design the new spaceship and the crew’s accommodation. What shape will you give the new spaceship? What factors will you consider before deciding on the shape? Explain. Sketch your design.arrow_forwardA CNC milling machine has a purchase price of £120,000 and it is considered from an accounting standpoint to be depreciated to zero value over a period of 5 years. If the machine is to be used for 2 shifts with each shift working for 37 hours/ week and 45 weeks/ year. What is the machine cost/ hr which must be charged in order to amortise/repay the costs over the 5 year period? To make the calculation simpler, you can assume that over the 5 year period you will be required to pay back 8% interest on the sum borrowed. Express your answer in § / hour rounded up to the nearest pennyarrow_forward

- could you sort this solution out for me please i cant see the sentences fully . could you rewrite it for mearrow_forwardNeed only handwritten solutionarrow_forwardTable 1: Mechanical behavior of human cadaver tibial bones during pure torsional loads applied with the proximal tibia fixed and the torque applied to the distal tibia until there is bone fracture. Medial condyle Tibial tuberosity- Medial malleolus -Lateral condyle Head of fibula Ti-6Al-4V grade 5 Stainless Steel 316L Region of bone resection -Lateral malleolus L = 365 mm Annealed Annealed Torque at ultimate failure (bone fracture) Displacement (twist angle) at ultimate failure Torsional Stiffness Table 2: Mechanical properties of candidate materials for the rod. Material Process Yield Strength (MPa) 880 220-270 Do = 23 mm Elastic Modulus (GPa) 115 190 d₁ = 14 mm Figure 1: Representative tibia bone showing the resection region (blue arrows) and median length (L). A circular cross section of distal tibia taken at the level of resection) showing the median inner (di) and outer (Do) diameters of the cortical bone. A tibia bone after resection with the proposed metal solid rod (black line)…arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY