Use Excel to solve the linear programming problem.

At one of its factories, a manufacturer of televisions makes one or more of four models of HD units (without cases): a 20-in. LCD, a 42-in. LCD, a 42-in. plasma, and a 50-in. plasma. The assembly and testing time requirements for each model are shown in the table, together with the maximum amounts of time available per week for assembly and testing. In addition to these constraints, the supplier of cases indicated that it would supply no more than 290 cases per week and that of these, no more than 40 could be for the 20-in. LCD model.

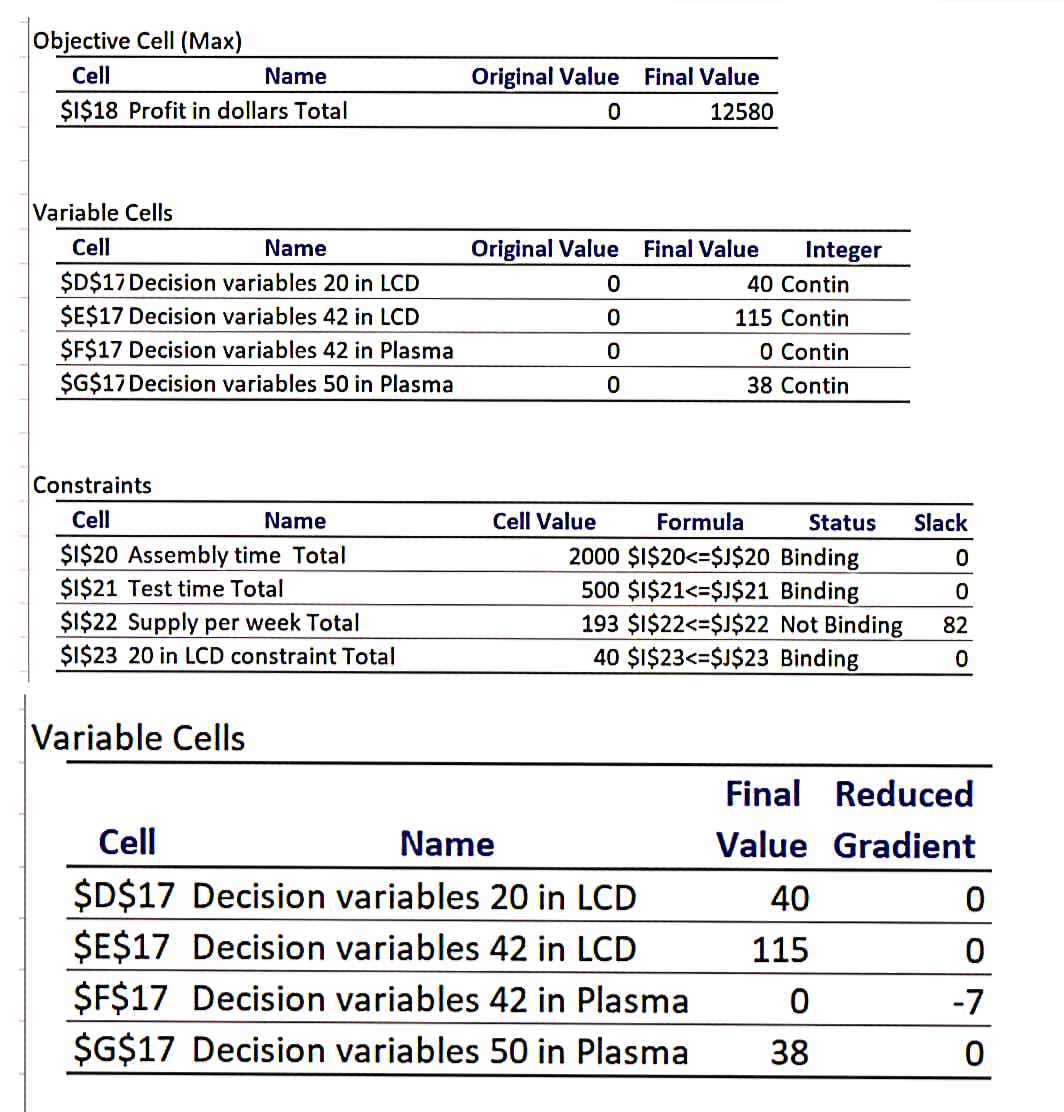

Use the profit for each television shown in the table to find the number of completed models of each type that should be produced to obtain the maximum profit for the week. Find the maximum profit.

| 20-in. LCD | sets | |

| 42-in. LCD | sets | |

| 42-in. plasma | sets | |

| 50-in. plasma | sets | |

| profit | $ |

| 20-in. LCD |

42-in. LCD |

42-in. Plasma |

50-in. Plasma |

Total Available |

|

|---|---|---|---|---|---|

| Assembly time (hours) |

7 | 10 | 12 | 15 | 2000 |

| Test time (hours) |

2 | 2 | 4 | 5 | 500 |

| Profit (dollars) |

48 | 60 | 73 | 100 |

The complete solutions are given below

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

- Ethan Steel, Inc. has three factories that manufacture steel components for three different rail projects located at three different sites. They want to determine how many steel components must be transported from each factory to each project site. The demand for the steel components for the three projects, A, B and C, are 2500, 3000 and 4500, respectively. The production and shipping details are as below: Production details: Factory Maximum capacity 1 3000 5000 3000 2 3 Shipping details (with per-unit shipping cost in dollars): Project Factory A B C 1 7 8 2 2 6 5 4 3 1 9 6 Develop a linear programming optimization model to determine the distribution plan (from factories to projects) that minimizes the total transportation cost. (Do NOT solve the model.)arrow_forwardA manufacturer has two factories, located in Toronto and Winnipeg. Warehouses are located in Moncton, Montreal, and Calgary. Minimum requirements at the three warehouses are for at least 5 000, 8 000, and 7 000 units, respectively. The production capacities of the two factories are 9 000 and 11 000 units, respectively. Shipping costs per unit from each factory to each warehouse are given below: FACTORY Moncton Toronto WAREHOUSE $14 $22 $6 Winnipeg $17 The manufacturer wants to determine the optimal shipping schedule that will minimize transportation costs. Formulate the linear programming model for this problem. Montreal Calgary $18 $9arrow_forwardThere are three factories located at AR, IN, and TX respectively. From these locations, a certain commodity is to be delivered to each of the two warehouses situated at A and B. The revenue per commodity item is $10. The weekly demand of the warehouse A and B are respectively 50 and 35 units of the commodity while the production capacity of the factories at AR, IN, and TX are respectively 28, 22, and 35 units. The cost of transportation per unit is given as belows. Cost Warehouse A Warehouse B AR 5 3 IN 6 6 TX 2 4 To maintain a good relationship with all the factories, warehouse B requires that it receives at least 40% of its product from factory in TX. Realize that it is making good profit in warehouse A, AR requires that at least 35% of its product shipped to warehouse A. Formulate (without solving) a linear programming problem to maximize the profit.arrow_forward

- For his classes, Professor Wright gives three types of quizzes, objective, recall, and recall-plus. To keep his students on their toes, he has decided to give at least 20 quizzes next quarter. The three types, objective, recall, and recall-plus quizzes, require the students to spend, respectively, 10 minutes, 30 minutes, and 60 minutes for preparation, and Professor Wright would like them to spend at least 12 hours(720 minutes) preparing for these quizzes above and beyond the normal study time. An average score on an objective quiz is 5, on a recall type 6, and on a recall-plus 7, and Dr. Wright would like the students to score at least 130 points on all quizzes. It takes the professor one minute to grade an objective quiz, 2 minutes to grade a recall type quiz, and 3 minutes to grade a recall-plus quiz. How many of each type should he give in order to minimize his grading time?arrow_forwardTerra Mesa Manufacturing uses a job order cost system to account for its production of specialty patio furniture. At the beginning of June, Terra Mesa had one job in Work in Process, job A75. Management has chosen direct labor cost as its activity base. The costs incurred to date on job A75 are as follows: Direct materials $8260 Direct labor 10500 Overhead 13125 During June, Terra Mesa added the following costs for direct materials and direct labor to job A75: Direct materials $2630 Direct labor 4620 Job A75 was competed on June 30. What is the cost of job A75? $26010 $39135 $44910 $42831arrow_forwardAnela is a computer scientist who is formulating a large and complicated program for a type of data processing. She has three ways of storing and retrieving data: cloud storage, disk, or hard drive. As an experiment, she sets up her program in three different ways: one using cloud storage, one using disks, and the other using a hard drive. Then she makes four test runs of this type of data processing on each program. The time required to execute each program is shown in the following table (in minutes). Use a 0.01 level of significance to test the hypothesis that the mean processing time is the same for each method. Hard Drive Cloud Disks 8.8 7.5 7.1 8.8 9.2 6.6 8.0 7.2 10.2 7.6 7.9 8.0 (i) Give the value of the level of significance. (ii) Find the sample test statistic. (Round your F Ratio to two decimal places. Round all other answers to four decimal places.) (vi) In the case of one-way ANOVA, make a summary table. (Round your answers to three decimal places.)…arrow_forward

- TMA manufactures 37-in. high-definition LCD televisions in two separate locations: Location I and Location II. The output at Location I is at most 6500 televisions/month, whereas the output at Location II is at most 5000 televisions/month. TMA is the main supplier of televisions to Pulsar Corporation, its holding company, which has priority in having all its requirements met. In a certain month, Pulsar placed orders for 2600 and 4100 televisions to be shipped to two of its factories located in City A and City B, respectively. The shipping costs (in dollars) per television from the two TMA plants to the two Pulsar factories are as follows. To Pulsar Factories From TMA City A City B Location I $7 $4 Location II $8 $8 TMA will ship x televisions from Location I to City A and y televisions from Location I to City B. Find a shipping schedule that meets the requirements of both companies while keeping costs, C (in dollars), to a minimum. Minimize C =…arrow_forwardIn her last semester at SPC, Polly Hedron needs to take Statistics, Composition 2, and Ethics. Because Polly is registering early, she has 14 choices for her section of Statistics, 14 choices for her section of Composition, and 13 choices for her section of Ethics. From how many possible schedules can Polly choose? (You may presume that none of these sections interfere with each other)arrow_forwardYou are in charge of purchases at the student-run used-book supply program at your college, and you must decide how many introductory calculus, history, and marketing texts should be purchased from students for resale. Due to budget limitations, you cannot purchase more than 900 of these textbooks each semester. There are also shelf-space limitations: Calculus texts occupy 2 units of shelf space each, history books 1 unit each, and marketing texts 2 units each, and you can spare at most 1,400 units of shelf space for the texts. If the used book program makes a profit of $10 on each calculus text, $4 on each history text, and $8 on each marketing text, how many of each type of text should you purchase to maximize profit?arrow_forward

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated

Advanced Engineering MathematicsAdvanced MathISBN:9780470458365Author:Erwin KreyszigPublisher:Wiley, John & Sons, Incorporated Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education

Numerical Methods for EngineersAdvanced MathISBN:9780073397924Author:Steven C. Chapra Dr., Raymond P. CanalePublisher:McGraw-Hill Education Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY

Introductory Mathematics for Engineering Applicat...Advanced MathISBN:9781118141809Author:Nathan KlingbeilPublisher:WILEY Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,

Mathematics For Machine TechnologyAdvanced MathISBN:9781337798310Author:Peterson, John.Publisher:Cengage Learning,