Operations Management: Processes And Supply Chains (12th Global Edition) - Does Not Include Mylab Operations Management

12th Edition

ISBN: 9780134890357

Author: Lee J. Krajewski, Manoj K. Malhotra

Publisher: Pearson Global Edition

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 10, Problem 18P

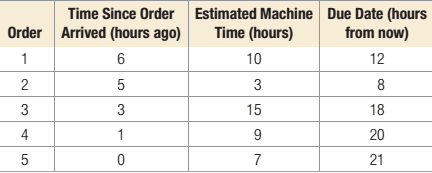

The Hickory Company manufactures wooden desks. Management

The due dates reflect the need for the order to be at its next operation.

- Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average past due hours.

- Comment on the performance of the two rules relative to these measures.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

A process improvement team is working to improve the production output at the Johnson Manufacturing plant’sHeader Cell that manufactures a key component, headers, used in commercial air conditioners. A header is partof the circulatory system of a commercial air conditioner that moves coolant between various components suchas the evaporator coil and the condenser coil. Currently, the header production cell is scheduled separately fromthe main work in the plant. Often, individual headers are not sequenced to match the product they go into on thefinal assembly line in a timely fashion, and so the product can sit in queue waiting for a header

Using the FCFS rule for scheduling, the sequence is

Sunny Park Tailors has been asked to make three different

types of wedding suits for separate customers. The table

below highlights the time taken in hours for cutting and

sewing (process 1) and delivery (process 2) of each of the

suits

Times Taken for Different Activities (hours)

Cut and Sew

Suit

1

2

3

7

4

5

Deliver

2

3

6

Assume that orders for suits have been listed in the above

table in the order in which they were received.

C

Joan has a small design and tailoring shop making custom outfits for women. She has two employees. Each employee only begins working on a dress when a customer order has

been received and then she makes the dress from beginning to end. The average production time of a dress is 1.8 days, with a standard deviation of 2.1 days. Historically, Joan has

been receiving orders with interarrival times of one day on average. The interarrival times of orders have a coefficient of variation of one.

(Carry at least 4 decimal places in all intermediate calculations. Round your final answer to 2 decimal places.)

What is the expected waiting time, in days, between when an order is received and when production begins on the dress?

A. 9.12 days B. 6.50 days C. 1.23 days D.3.41 days

Chapter 10 Solutions

Operations Management: Processes And Supply Chains (12th Global Edition) - Does Not Include Mylab Operations Management

Ch. 10 - List the types of costs incurred when employees...Ch. 10 - Prob. 2DQCh. 10 - Prob. 3DQCh. 10 - Explain why management should be concerned about...Ch. 10 - The Barberton Municipal Division of Road...Ch. 10 - Bob Canton’s golf camp estimates the following...Ch. 10 - Prob. 3PCh. 10 - Prob. 4PCh. 10 - Management at the Kerby Corporation has determined...Ch. 10 - Gretchen’s Kitchen is a fast-food restaurant...

Ch. 10 - Prob. 7PCh. 10 - Tax Prep Advisers, Inc. has forecasted the...Ch. 10 - Climate Control, Inc. makes expedition-quality...Ch. 10 - Prob. 11PCh. 10 - Gemini Inc. is using the Sales and Operations...Ch. 10 - Gerald Glynn manages the Michaels Distribution...Ch. 10 - Cara Ryder manages a ski school in a large resort...Ch. 10 - Prob. 15PCh. 10 - Prob. 17PCh. 10 - The Hickory Company manufactures wooden desks....Ch. 10 - Prob. 19PCh. 10 - The Mowry Machine Shop still has five jobs to be...Ch. 10 - If we use the same number of workers in each...Ch. 10 - Prob. 2AMECh. 10 - Prob. 3AMECh. 10 - Suppose the overtime cost is $3,300. What happens...Ch. 10 - Suppose the undertime cost is the same as the...Ch. 10 - Prob. 6AMECh. 10 - Prob. 1VCCh. 10 - Does Starwood employ a chase, level, or mixed...Ch. 10 - How would staffing for the opening of a new hotel...Ch. 10 - Explain the alternatives available to Darlene Fry...Ch. 10 - Prob. 2C

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Currently a company that designs Web sites has five customers in its backlog. The time since the order arrived, processing time, and promised due dates are given in the following table. The customers are ready to be scheduled today, which is the start of day 190. Customer Time Since Order Arrived (days ago) Processing Time (days) Due Date (days from now) Upper AA 6 18 66 Upper BB 3 24 58 Upper CC 2 32 100 Upper DD 10 22 26 Upper EE 8 12 50 a. Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average days past due. Part 2 Using the FCFS (first come, first served) decision rule for sequencing the customers, the order is: Sequence 1 2 3 4 5 Customer D E A B C Part 3 Using…arrow_forward12-13 Mike Dreskin manages a large Los Angeles movie theater complex called Cinema I, II, III, and IV. Each of the four auditoriums plays a different film; the schedule is set so that starting times are staggered to avoid the large crowds that would occur if all four movies started at the same time. The theater has a single ticket booth and a cashier who can maintain an average service rate of 280 movie patrons per hour. Service times are assumed to follow an exponential distribution. Arrivals on a typically active day are Poisson distributed and average 210 per hour. To determine the efficiency of the current ticket operation, Mike wishes to examine several queue operating characteristics. a. Find the average number of moviegoers waiting in line to purchase a ticket. b. What percentage of the time is the cashier busy? c. What is the average time that a customer spends in the system? d. What is the average time spent waiting in line to get to the ticket window? e. What is the…arrow_forwardYour team has been assigned to complete 10 client projects over the next two months. These projects and their processing times (time taken to complete a project once started, in days) are described in the table below. In addition, each project has a due-date that has been set by your internal marketing team so that the customers will be delighted with your service if you complete the project by the due-date. However, your team has only enough resources to pursue exactly one project at any given time. Once started, a project is worked through its completion and is not interrupted. As a result of the sequence in which you choose to handle projects, each project will either be on time, or late if it is completed past the due date. If a project is late, the amount of time by which it misses its due-date is called its tardiness. The objective is to pick the sequence in which to complete the projects so as to minimize the total tardiness in the schedule. What is the minimum total tardiness…arrow_forward

- The maintenance department of an Oil and Gas Company has 6 large drilling equipment waiting for repairs. These are labelled A, B, C, D, E and F. The respective repair times (in days) and the remaining days before the due date are given in the table below.arrow_forwardJobs A, B, C, and D are in queue at work center 10 before being completed on work center 20. The table below pertains to the jobs and the work centers: (Job, Process time (day) at WC 10, process time (day) at WC 20, Due Date, arriving order). Today is day 1. Job Process Time ABCD Work Center Work Center 10 20 3 4 3 3 3 5 4 1 Due DateArriving order 8 24 18 15 2143 D If the jobs are scheduled by the shortest process time (SPT) rule, the total idle time (total of both WCs) during day 1 through day end (last job finishing date) is: Hint: you need to first determine the job's operation order by SPT rule. Then in each work center, you need to schedule each job's start date and end date on both WCs. 12 11 10 9 None of themarrow_forwardHow do standard circular flow and expanded circular flow differ?arrow_forward

- AssumMe a customer orders a product online. SupPpose that the product is delivered later in the weEek. The time between the order placement and order delivery is known as: a. waitT time b. queue time c. cycle time d. process timearrow_forwardFive jobs are waiting for processing through two work centers. Their processing time (in minutes) at each work center is contained in the table below. Each job requires work center Sigma before work center Delta. According to Johnson's rule, what sequence of jobs will minimize the completion time for all jobs? Job Sigma Delta R 20 10 S 25 30 T 30 20 U 35 35 V 15 25 Part 2 A. V−S−U−T−R B. V−R−U−S−T C. R−V−T−S−U D. S−U−T−V−R E. R−S−T−U−Varrow_forwardPanini, a popular sandwich shop, offers 3 types of sandwiches: grilled vegetables, grilled chicken, and pastrami. The table below provides demand data: Grilled Vegetables Grilled Chicken Pastrami Demand per hour 25 9 12 There are up to five steps in the process of making sandwiches listed below with activity times (if no activity time, then than step is not done for that sandwich). Only 50% of customers want their sandwich toasted, no matter which sandwich is ordered. Step Grilled Vegetables(in minutes) Grilled Chicken(in minutes) Pastrami(in minutes) Cut bread 1 1 1 Grill 1.2 1.2 Slice meat 2 Toast 1.2 1.2 1.2 Wrap 0.8 0.8 0.8 Suppose Panini employs 1 worker at each step. a) Does Panini have enough capacity to fulfill the current demand for sandwiches? (b) What is the current capacity cushion for Panini? (as a %) c) If demand for Pastramis increase with the percentage indicated below, how much additional workers should Panini hire (if any), and where…arrow_forward

- (Business Analytics) I need some help on this problem, I'm not sure what to do. Problem 2) Larry Edison is the director of the Computer Center for Buckly college. He now needs to schedule the staffing of the center. It is open from 8:00 AM until midnight. Larry has monitored the usage of the center at various times of the day and determined that the following number of computer consultants (qualified graduate students) are required. Time of Day Minimum Number of Consultants Required to be on Duty 8 AM – Noon 6 Noon – 4 PM 8 4 PM – 8 PM 12 8 PM - Midnight 6 Two types of computer consultants can be hired: full-time and part-time period the full-time consultants work for eight consecutive hours in any of the following shifts: mornings (8 AM - 4:00 PM), afternoon (noon - 8:00 PM), and evenings (4:00 PM to midnight). Full-time consultants are paid $17.50 per hour. Part-time consultants can be hired to work any of the four…arrow_forwardBE Spreadsheet Mike Reynolds has four assignments due in class tomorrow, and his class times are as follows: Time 9 a.m. 12 p.m. 2 p.m. 5:30 p.m. Each class lasts one hour, and Mike has no other classes. It is now midnight, and Mike estimates that the marketing, finance, psychology, and OM assignments will take him one, four, five, and seven hours, respectively. Assume that all time till the last class begins can be spent on completing assignments but each assignment should be done till the time of the class on the same subject. (Mike can prepare assignments for the next classes during previous classes.) Use the Excel Sequencing template to determine how he should schedule the work. Use minus sign to enter negative lateness values, if any. Enter the half an hour value as 0.5, e.g., 3:30 p.m. should be entered as 15.5. If your answer is zero, enter "0". Round your answers for the due date, lateness, and tardiness to one decimal place. Round your answers for the average values to two…arrow_forwardADVANCED ANALYSIS Linear equations for the consumption and saving schedules take the general form: C = a + bY and S = -a + (1-b)Y where C, S, and Y are consumption, saving, and national income, respectively. The constant a represents the vertical intercept, and b represents the slope of the consumption schedule. a. Use the following data to substitute specific numerical values into the consumption and saving equations. Instructions: If you are entering any negative numbers be sure to include a negative sign (-) in front of those numbers. C = $ Y. S = $ Y. b. What is the economic meaning of b? . What is the economic meaning of (1 – b)? .arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY