Concept explainers

(a)

To select:

The pump that runs at the given speed performing the task with efficiency being maximum.

Answer to Problem 11.4CP

The pump that runs at the given speed performing the task with efficiency being maximum is determined below.

Explanation of Solution

Given Information:

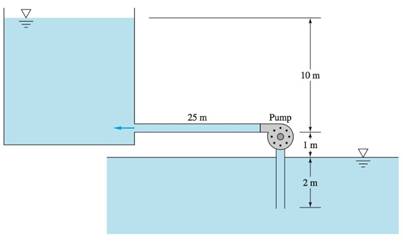

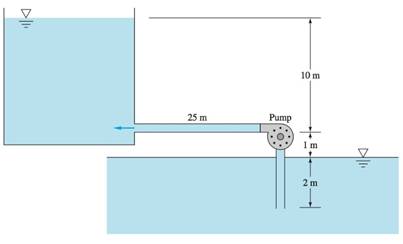

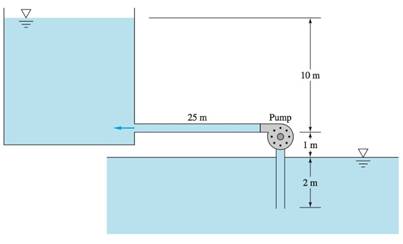

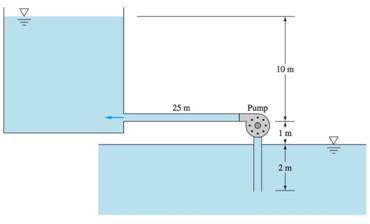

The given figure,

The system delivers 20-degree Celsius water from the sea level reservoir to another iron pipe with diameter 38 cm.

Minor loss before pump entrance

Minor loss after pump entrance

Concept Used:

Velocity of the flow:

Calculation:

According to the figure:

Reynold’s number:

Density

Dynamic Viscosity

Diameter=380mm

Volume=12.24m/s

Substituting the values:

The flow is turbulent.

Friction factor is given as:

Head loss using the friction factor is calculated.

Using equation (1)

Frictional heal loss is calculated using flow rates having different values:

| Q(gal/min) | 4000 | 8000 | 12000 | 16000 | 20000 | 22000 | 24000 |

| |

44 | 66 | 103 | 156 | 223 | 262 | 305 |

From the table and the reference figure at the flow rate of 20,000 gal/min, 88% efficiency. Hence the pump is given as 38 in.

Conclusion:

Thus, the pump that runs at the given speed performing the task with efficiency being maximum is determined.

(b)

To calculate:

The flow rate.

Answer to Problem 11.4CP

The flow rate is given as 20,000 gal/min

Explanation of Solution

Given Information:

The given figure:

The system delivers 20-degree Celsius water from the sea level reservoir to another iron pipe with diameter 38 cm.

Minor loss before pump entrance

Minor loss after pump entrance

Concept Used:

Velocity of the flow:

Calculation:

Reynold’s number

Density

Dynamic Viscosity

Diameter=380mm

Volume=12.24m/s

Substituting the values:

The flow is turbulent.

Friction factor is given as:

Head loss using the friction factor is calculated:

Using equation (1)

Frictional heal loss is calculated using flow rates having different values:

| Q(gal/min) | 4000 | 8000 | 12000 | 16000 | 20000 | 22000 | 24000 |

| |

44 | 66 | 103 | 156 | 223 | 262 | 305 |

Conclusion:

Thus, the flow rate is determined.

(c)

Brake horse power.

Answer to Problem 11.4CP

Brake horse power=1250hp

Explanation of Solution

Given Information:

The given figure,

The system delivers 20-degree Celsius water from the sea level reservoir to another iron pipe with diameter 38 cm.

Minor loss before pump entrance

Minor loss after pump entrance

Concept Used:

Calculation:

Substituting we have:

Conclusion:

Thus, the brake horse power is calculated.

(d)

The given pump is safe from cavitation.

Answer to Problem 11.4CP

The pump replacement is needed as the pump will cavitate.

Explanation of Solution

Given Information:

The given figure:

The system delivers 20-degree Celsius water from the sea level reservoir to another iron pipe with diameter 38 cm.

Minor loss before pump entrance

Minor loss after pump entrance

Concept Used:

Calculation:

Substituting we have:

For the flow rate Q=20000gal/min, the NPSH=16m(-0.36m).

So, the pump cavitates.

Conclusion:

Thus, the given pump is safe from cavitation is determined.

Want to see more full solutions like this?

Chapter 11 Solutions

Loose Leaf For Fluid Mechanics

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY