Concept explainers

SummerFun. Inc., produces a variety of recreation and leisure products. The

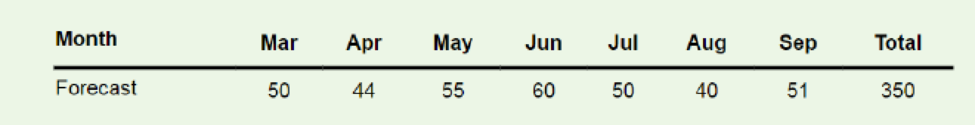

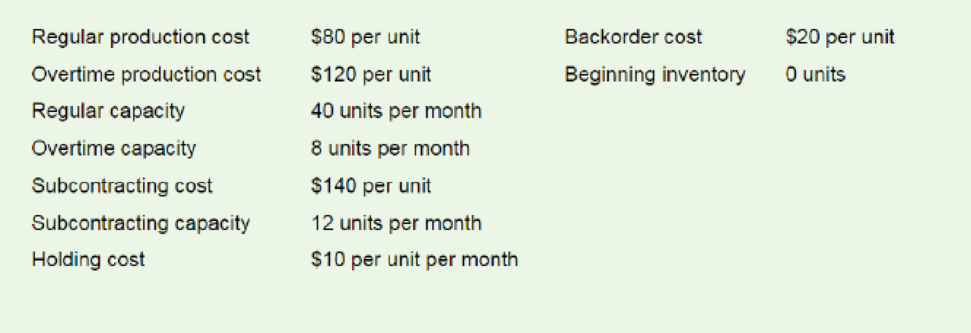

Use the following information to develop aggregate plans.

Develop an aggregate plan using each of the following guidelines and compute the total cost for each plan. Hint: You will need extra output in April and August to accommodate demand in the following months.

a. Use regular production. Supplement using inventory, overtime, and subcontracting as needed. No backlogs allowed.

b. Use a level strategy. Use a combination of backlogs, subcontracting, and inventory to handle variations in demand. There should not be a backlog in the final period.

a)

To determine: The total cost using an aggregate plan.

Introduction:The aggregate plan is the output of sales and operations planning. The major concern of aggregate planning is the production time and quantity for the intermediate future. Aggregate planning would encompass a time prospect of approximately 3 to 18 months.

Answer to Problem 7P

Explanation of Solution

Given information:

Regular production cost is $80, overtime production cost is $120, subcontracting cost is $140, backorder cost is $20, holding cost is $10, regular capacity is 40 units, overtime cost is 8 units, and subcontracting capacity is 12 units. Beginning inventory is given as 0 units. In addition to this forecast for 7 months is given as follows:

| Month | March | April | May | June | July | August | September | Total |

| Forecast | 50 | 44 | 55 | 60 | 50 | 40 | 51 | 350 |

Determine the total cost of the plan:

It is given that regular productions should be used. No backlogs are allowed. Supplements can be satisfied using overtime, subcontracting, and inventory.

Supporting explanation:

Forecast and regular time capacity are given. Regular time capacity is given as 40 units, remaining units should be produced using the overtime capacity. Maximum overtime capacity is given as 8 units. Thus, if the forecast is not satisfied, it can be produced using the subcontract:

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 0 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -4 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 4 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 2. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $280.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 3. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $420.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $2,660.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Note: The calculation repeats for all the months.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $31,250.

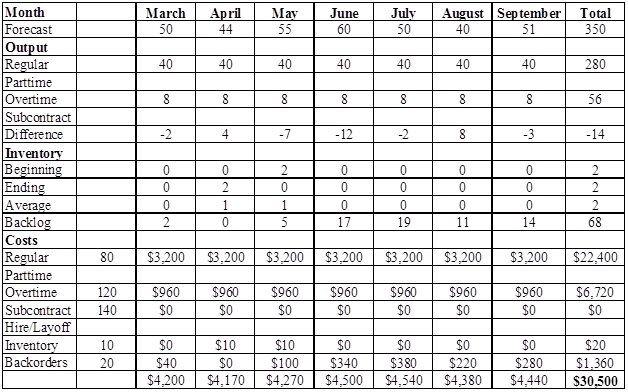

b)

To determine: The total cost using a level strategy of aggregate planning.

Introduction:Level production strategy is a production strategy used to produce at a constant rate. This strategy keeps constant level of workforce and backlog of demand.

Answer to Problem 7P

Explanation of Solution

Given information:

Regular production cost is $80, overtime production cost is $120, subcontracting cost is $140, backorder cost is $20, holding cost is $10, regular capacity is 40 units, overtime cost is 8 units, and subcontracting capacity is 12 units. Beginning inventory is given as 0 units. In addition to this forecast for 7 months is given as follows:

| Month | March | April | May | June | July | August | September | Total |

| Forecast | 50 | 44 | 55 | 60 | 50 | 40 | 51 | 350 |

Determine the total cost of the plan:

Subcontracting, inventory, and backlogs can be used to handle the fluctuations in the demand. Initial solution using regular time and overtime without using subcontracting is as follows:

Supporting explanation:

Determine the regular time productivity:

It is calculated by taking an average of the given forecast.

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -2 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is --7 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Difference between output and forecast is 2 (4-2). Hence, the ending inventory is 2 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 1unit.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 1unit.

Note: The calculation repeats for all the months.

Backlogs for the month of 1:

It is number of units required in the month. As there is no previous month for 1st month, the difference would be the backlog. Hence, the backlog for 1st is 2 units.

Backlogs for the month of 2:

As the difference is positive, there would not be backlog.

Backlogs for the month of 3:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 5 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $140.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $0.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $10.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $10.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $40.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $100.

Note: The calculation repeats for all the months.

Calculate the total backorder cost:

It is calculated by adding the backorder cost of all the months.

Hence, the total backorder cost is $1,360.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $30,500.

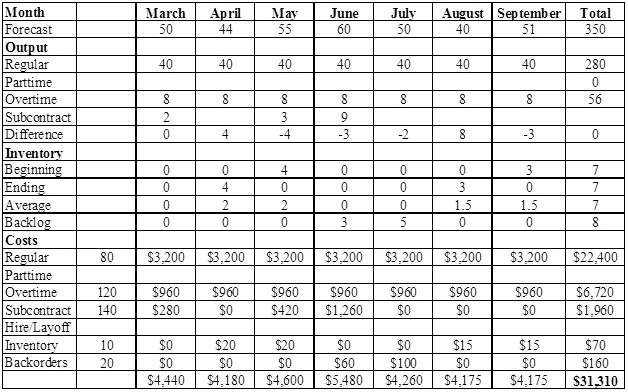

Determine the total cost of the plan:

Subcontracting, inventory, and backlogs can be used to handle the fluctuations in the demand. Final solution using regular time, overtime, and subcontracting is as follows:

Supporting explanation:

Determine the regular time productivity:

It is calculated by taking an average of the given forecast.

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 0 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -4 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 4 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Note: The calculation repeats for all the months.

Backlogs for the month of June:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 3 units.

Backlogs for the month of July:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 5 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 2. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $280.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 3. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $420.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $1,960.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Note: The calculation repeats for all the months.

Calculate the total backorder cost:

It is calculated by adding the backorder cost of all the months.

Hence, the total backorder cost is $160.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $31,310.

Want to see more full solutions like this?

Chapter 11 Solutions

OPERATIONS MANAGEMENT (LL) >CUSTOM<

- Southeast Soda Pop, Inc., has a new fruit drink forwhich it has high hopes. John Mitten thai, the production planner,has assembled the fo llowing cost data and demand forecast: John's job is to develop an aggregate plan. The three initialoptions he wants to evaluate are:• Plan A: a strategy that hires and fires personnel as necessaryto meet the forecast.• Plan B: a level strategy.• Plan C: a level strategy that produces 1,200 cases per quarterand meets the fo recast demand with inventory and subcontracting.a) Which strategy is the lowest-cost plan?b) If you are John's boss, the VP for operations, which p lan doyou implement and why?arrow_forwardDevelop a chase aggregate plan for Draper using apermanent workforce of 12 employees supplemented by overtime.All demand must be met each period.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.arrow_forwardManager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a regular output capacity of 135 engines per month. Regular output has a cost of $60 per engine. The beginning inventory is zero engines. Overtime has a cost of $100 per engine. a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Regular production can be less than regular capacity. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" wherever required.) b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $120 per engine per month. There should not be a backlog in the last month. Set regular production equal to the monthly average of total forecasted demand. Assume that using overtime is not an option. (Negative amounts…arrow_forward

- 3. What information is necessary for an operations manager to create the aggregate plan? List the capacity options and demand options of aggregate planning and explain the difference between them. Which strategy or model always gives the aggregate plan with the minimum total cost?arrow_forwardDeb Bishop Health and Beauty Products has developeda new shampoo, and you need to develop its aggregate schedule.The cost accounting department bas supplied you the costsrelevant to the aggregate plan, and the marketing department hasprovided a four-quarter forecast. All are shown as follows: Your job is to develop an aggregate plan for the next four quarters.a) First, try hiring and layoffs (to meet the forecast) as necessary.b) Then try a plan that holds employment steady.c) Which is the more economical plan for Deb Bishop Healthand Beauty Products?arrow_forwardJAYB, manager of a Fabrication company, has the following aggregate demand requirements and other data for the upcoming four quarters. Table 5: Forecast and cost information [Jadual 5: Maklumat Ramalan dan kos] Quarter [Suku] Demand [Permintaan] Previous quarter's output [Keluaran suku sebelumnya] 1,500 units 1 1,400 Beginning inventory [Inventori awal] 200 units 2 1,000 Hiring workers [Pengambilan pekerja] RM6 per unit 3 1,500 Laying off workers [Pembuangan pekerja] RM11 per unit 4 1,300 Unit cost [Kos unit] RM30 per unit With the information given, JAYB wants you to calculate the total cost of using chase strategy by hiring and layoff workers.arrow_forward

- Explain the different capacity based options used in aggregate planning and their implications for business ?arrow_forwardList the capacity options and demand options of aggregate planning and explain the difference between them. Which strategy or model always gives the aggregate plan with the minimum total cost?arrow_forwardHow is it possible for you to solve the Aggregate Planning problem?arrow_forward

- What detail is required to build the aggregate schedule for an operations manager? List and illustrate the distinction between the capability options and the demand options for aggregate preparation. The approach or formula always provides the overall minimal cost for the overall plan?arrow_forwardA forecast of 320 units in January, 400 units in February,and 240 units in March has been approved for the seismic-sensory product family manufactured at the Rockport facilityof Maryland Automated, Inc. Three products, A, B, and C,comprise this family. The product mix ratio for products A,B, and C for the past 2 years has been 35 percent, 40 percent,and 25 percent, respectively. Management believes that themonthly forecast requirements are evenly spread over the4 weeks of each month. Currently, 15 units of product C areon hand. The company produces product C in lots of 40, andthe lead time is 2 weeks. A production quantity of 40 unitsfrom the previous period is scheduled to arrive in week 1. Thecompany has accepted orders of 25, 9, 11, 5, 4, and 9 unitsof product C in weeks 1 through 6, respectively. Prepare aprospective MPS for product C and calculate the available-to-promise inventory quantitiesarrow_forwardDeb Bishop Health and Beauty Products has developed a new shampoo and you need to develop its aggregate schedule. The cost accounting department has supplied you the cost relevant to the aggregate plan and the marketing department has provided a four-quarter forecast. the four-quarter forecast. Quarter Forecast 1 1,400 2 1,100 3 1,700 4 1,300 the costs relevant to the aggregate plan. Costs Previous quarter's output 1,600 units Beginning inventory 0 units Stockout cost for backorders $55 per unit Inventory holding cost $11 per unit for every unit held at the end of the quarter Hiring workers $50 per unit Layoff workers $75 per unit Unit cost $35 per unit Overtime $20 extra per unit Subcontracting Not available Your job is to develop an aggregate plan for the next four quarters. Part 2 a) Try hiring and layoffs (to meet the forecast) as necessary…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.