Concept explainers

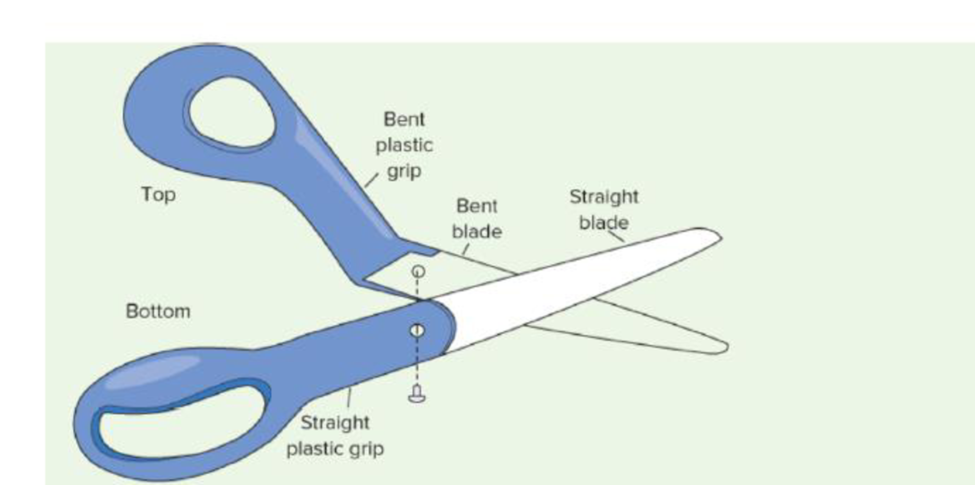

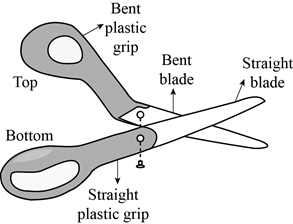

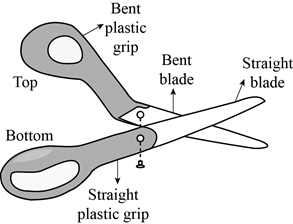

Using the accompanying diagram, do the following:

a. Draw a tree diagram for the scissors.

b. Prepare an MRP plan for scissors. Lead times are one day for each component and final scissor assembly, but two days for the plastic grips. Six hundred pairs of scissors are needed on day 6. Note: There are 200 straight blades and 350 bent blades on hand, and 40 top blade assemblies on hand.

Use lot-for-lot ordering for all items.

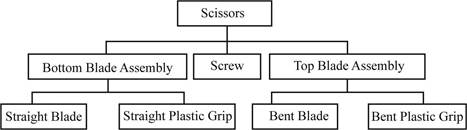

a)

To prepare: Tree diagram for the scissors.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

Lead-time is one day for all the components except plastic grips, which has the lead-time of 2 days. 600 pairs of scissors are needed on day 6. There are 350 bent blades, 200 straight blades, and 40 top blade assemblies on hand. Lot size is lot-for-lot ordering for all items.

In addition to that, following diagram is given:

Prepare tree diagram for the scissors using given diagram:

b)

To prepare: A Material requirement planning for scissors.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

Lead-time is one day for all the components except plastic grips, which has the lead-time of 2 days. 600 pairs of scissors are needed on day 6. There are 350 bent blades, 200 straight blades, and 40 top blade assemblies on hand. Lot size is lot-for-lot ordering for all items.

In addition to that, following diagram is given:

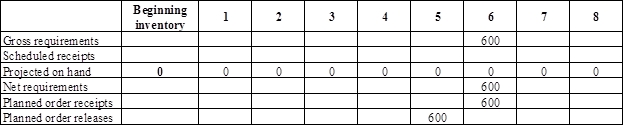

Develop material requirement planning for scissors:

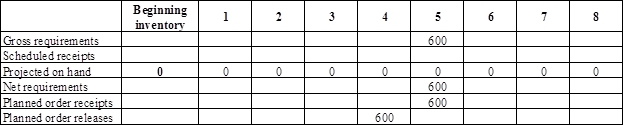

- It is given that 600 pairs of scissors are needed on day 6.

- Beginning inventory is 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 600 units in week 6 (600-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 600 units in the beginning of Week 6. Hence, they need to order for 600 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 5.

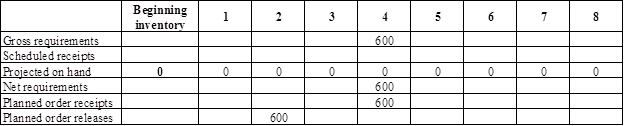

Develop material requirement planning for bottom blade assembly:

- Scissor is the parent for bottom blade assembly. Hence, the planned order release of the scissor would be the gross requirement of the bottom blade assembly. As number of units required is 1 for bottom blade assembly, the planned order release row of scissor should be multiplied with 1 to attain the gross requirement column of bottom blade assembly.

- Beginning inventory is 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 600 units in week 5(600-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 600 units in the beginning of Week 5. Hence, they need to order for 600 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

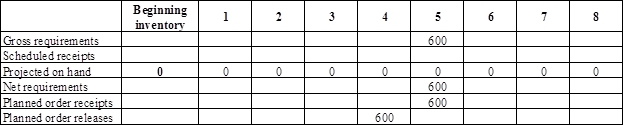

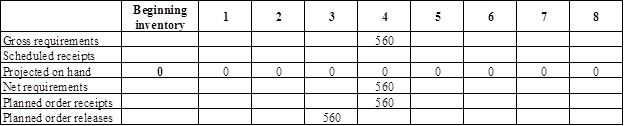

Develop material requirement planning for top blade assembly:

- Scissor is the parent for top blade assembly. Hence, the planned order release of the scissor would be the gross requirement of the top blade assembly. As number of units required is 1 for top blade assembly, the planned order release row of scissor should be multiplied with 1 to attain the gross requirement column of top blade assembly.

- Beginning inventory is 40 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 560 units in week 5 (600-40).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 560 units in the beginning of Week 5. Hence, they need to order for 560 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

- Projected on hand inventory for week 6 is 0 units. Calculation is as follows:

Develop material requirement planning for screw:

- Scissor is the parent for screw. Hence, the planned order release of the scissor would be the gross requirement of the screw. As number of units required is 1 for screw, the planned order release row of scissor should be multiplied with 1 to attain the gross requirement column of screw.

- Beginning inventory is 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 600 units in week 5 (600-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 600 units in the beginning of Week 5. Hence, they need to order for 600 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

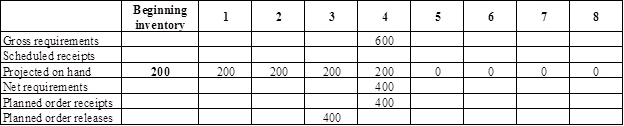

Develop material requirement planning for straight blade:

- Bottom blade assembly is the parent for straight blade. Hence, the planned order release of the bottom blade assembly would be the gross requirement of the straight blade. As number of units required is 1 for straight blade, the planned order release row of bottom blade assembly should be multiplied with 1 to attain the gross requirement column of straight blade.

- Beginning inventory is 200 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 400 units in week 4(600-200).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 400 units in the beginning of Week 4. Hence, they need to order for 400 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

Develop material requirement planning for straight plastic grip:

- Bottom blade assembly is the parent for straight blade. Hence, the planned order release of the bottom blade assembly would be the gross requirement of the straight blade. As number of units required is 1 for straight blade, the planned order release row of bottom blade assembly should be multiplied with 1 to attain the gross requirement column of straight blade.

- Beginning inventory is 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 600 units in week 4 (600-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. Company requires 600 units in the beginning of Week 4. Hence, they need to order for 600 units (as the lot size is lot-for-lot) before two weeks (as the lead-time is 2 weeks). Thus, company need to order the required units in week 3.

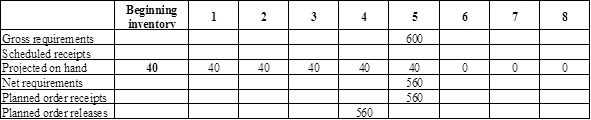

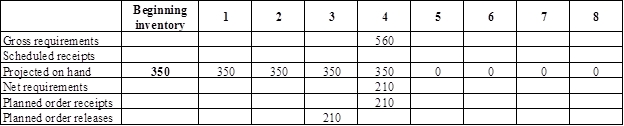

Develop material requirement planning for bent blade:

- Top blade assembly is the parent for bent blade. Hence, the planned order release of the top blade assembly would be the gross requirement of the bent blade. As number of units required is 1 for bent blade, the planned order release row of top blade assembly should be multiplied with 1 to attain the gross requirement column of bent blade.

- Beginning inventory is 350 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 210 units in week 4 (560-350).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 210 units in the beginning of Week 4. Hence, they need to order for 210 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

Develop material requirement planning for bent plastic grip:

- Top blade assembly is the parent for bent plastic grip. Hence, the planned order release of the top blade assembly would be the gross requirement of the bent plastic grip. As number of units required is 1 for bent plastic grip, the planned order release row of top blade assembly should be multiplied with 1 to attain the gross requirement column of bent plastic grip.

- Beginning inventory is 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 560 units in week 4 (560-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 560 units in the beginning of Week 4. Hence, they need to order for 560 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3

Want to see more full solutions like this?

Chapter 12 Solutions

Operations Management (McGraw-Hill Series in Operations and Decision Sciences)

Additional Business Textbook Solutions

Operations Management, Binder Ready Version: An Integrated Approach

Business in Action

Operations Management: Processes and Supply Chains (11th Edition)

Principles Of Operations Management

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

Operations Management: Processes and Supply Chains (12th Edition) (What's New in Operations Management)

- Note:- Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. Answer completely. 14.) A part structure, lead time (weeks), and on-hand quantities for product A are shown in Figure 14. From the information shown, generate: a) An indented bell of material for product A. b) Net requirements for each part to produce 10 As in week 8 using lot-for-lot. Figure 14:arrow_forwardProduct M is made of two units of N and two of P. N is made of two units of R and four units of S. R is made of one unit of S and three units of T. P is made of two units of T and four units of U. a. Show the bill-of-materials (product structure tree). b. If 100 Ms are required, how many units of each component are needed? c. Show both a single-level parts list and an indented parts list.arrow_forwardThe following table lists the components needed to assemble an end item, lead times (in weeks), and quantities on hand. Item Lead Time Amount Direct Components on Hand End 1 0 L(2), C(1), K(3) L 1 10 B(2), J(3) C 2 14 G(2), B(2) K 2 19 H(4), B(2) B 1 34 J 2 25 G 2 7 H 3 0 a. If 43 units of the end item are to be assembled, how many additional units of B are needed? b. An order for the end item is scheduled to be shipped at the start of week 9. What is the latest week that the order can be started and still be ready to ship on time?arrow_forward

- A part structure, lead time (weeks), and on-handquantities for product A are shown in Figure 14. 14. From theinformation shown, generate:a) An indented bill of material fo r product A b) Net requirements for each part to produce I0 As in week 8using lot-for-lot. IParrow_forwarda. Write the product structure diagram as an indented bill-of-materials list.arrow_forwardThe following table lists the components needed to assemble an end item, lead times (in weeks), and quantities on hand. Item Lead Time Amount on Hand Direct Components End 2 0 L(2), C(1), K(3) L 2 11 B(2), J(3) C 3 15 G(2), B(2) K 3 20 H(4), B(2) B 2 25 J 3 34 G 3 3 H 2 0 Click here for the Excel Data File a. If 43 units of the end item are to be assembled, how many additional units of B are needed? (Hint: You don’t need to develop an MRP plan.) b. An order for the end item is scheduled to be shipped at the start of week 11. What is the latest week that the order can be started and still be ready to ship on time? (Hint: You don’t need to develop an MRP plan.)arrow_forward

- The following table lists the components needed to assemble an end item, lead times (in weeks), and quantities on hand. Item Lead Time Amounton Hand Direct Components End 1 0 L(2), C(1), K(3) L 2 11 B(2), J(3) C 3 17 G(2), B(2) K 4 23 H(4), B(2) B 3 34 J 3 25 G 3 7 H 3 0 a. If 43 units of the end item are to be assembled, how many additional units of B are needed? (Hint: You don’t need to develop an MRP plan.) b.An order for the end item is scheduled to be shipped at the start of week 11. What is the latest week that the order can be started and still be ready to ship on time? (Hint: You don’t need to develop an MRP plan.)arrow_forwardThe following table lists the components needed to assemble an end item, lead times (in weeks),and quantities on hand. Item Lead Time Amount on Hand Direct ComponentsEnd 1 — L(2), C(1), K(3)L 2 10 B(2), J(3)C 3 15 G(2), B(2)K 3 20 H(4), B(2)B 2 30J 3 30G 3 5H 2 —a. If 40 units of the end item are to be assembled, how many additional units of B are needed?(Hint: You don’t need to develop an MRP plan.)b. An order for the end item is scheduled to be shipped at the start of week 8. What is the latestweek that the order can be started and still be ready to ship on time? (Hint: You don’t need todevelop an MRP plan.)arrow_forwardThe following table lists the components needed to assemble an end item, lead times (in weeks), and quantities on hand. Item Lead Time Amounton Hand Direct Components End 3 0 L(2), C(1), K(3) L 3 12 B(2), J(3) C 4 17 G(2), B(2) K 4 22 H(4), B(2) B 3 30 J 4 29 G 4 3 H 3 0 a. If 43 units of the end item are to be assembled, how many additional units of B are needed? (Hint: You don’t need to develop an MRP plan.)Additional units b. An order for the end item is scheduled to be shipped at the start of week 13. What is the latest week that the order can be started and still be ready to ship on time? (Hint: You don’t need to develop an MRP plan.) The latest weekarrow_forward

- A partially completed inventory record for the motor sub-assembly is shown in Figure 11.39. a. Complete the last three rows of the record by using the L4L rule. b. Complete the last three rows of the record by using the POQ rule with P = 2. c. Complete the last three rows of the record by using the POQ rule with P = 2. d. If it costs the company $1 to hold a unit in inventory from one week to the next, and the cost to release an order is $50, which of the lot sizing rules used above will provide the lowest inventory holding + order release cost?arrow_forwardProduct A is made from components B and C. Item B, inturn, is made from D and E. Item C also is an intermediateitem, made from F and H. Finally, intermediate item E ismade from H and G. Note that item H has two parents. Thefollowing are item lead times:a. What lead time (in weeks) is needed to respond to a cus-tomer order for product A, assuming no existing invento-ries or scheduled receipts?b. What is the customer response time if all purchased items(i.e., D, F, G, and H) are in inventory?c. If you are allowed to keep just one purchased item instock, which one would you choose?arrow_forwardProduct A is made from components B and C. Item B, inturn, is made from D and E. Item C also is an intermediateitem, made from F and H. Finally, intermediate item E ismade from H and G. Note that item H has two parents. Thefollowing are item lead times: a. What lead time (in weeks) is needed to respond to a cus-tomer order for product A, assuming no existing invento-ries or scheduled receipts?b. What is the customer response time if all purchased items(i.e., D, F, G, and H) are in inventory?c. If you are allowed to keep just one purchased item instock, which one would you choose?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.