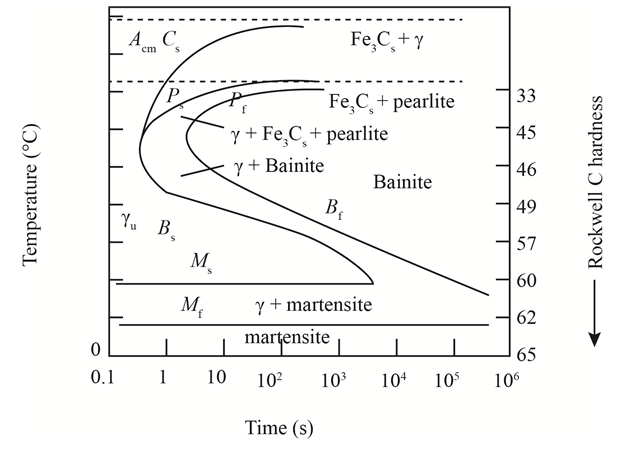

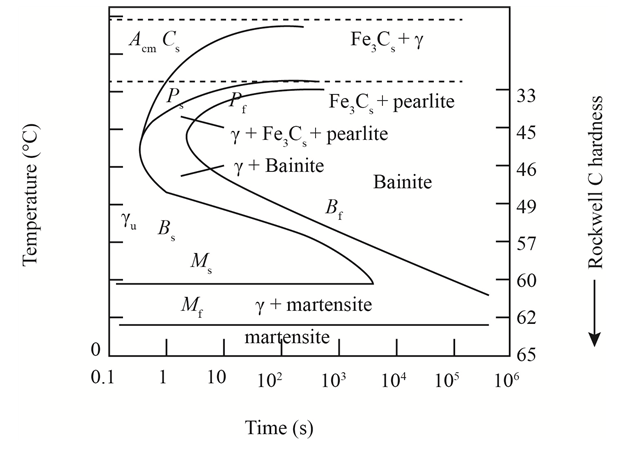

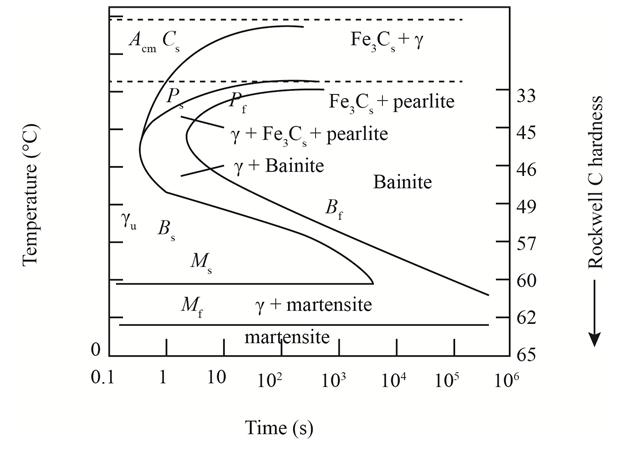

(a)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

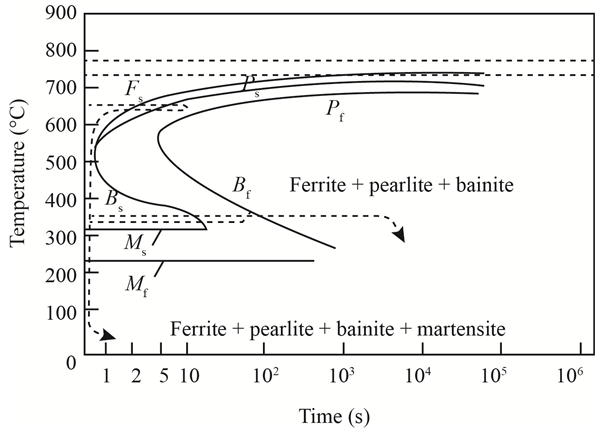

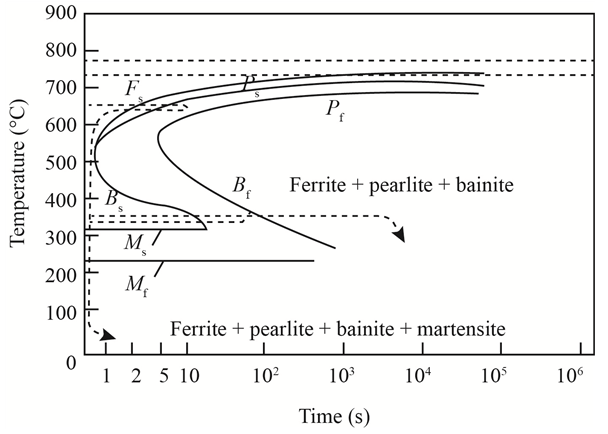

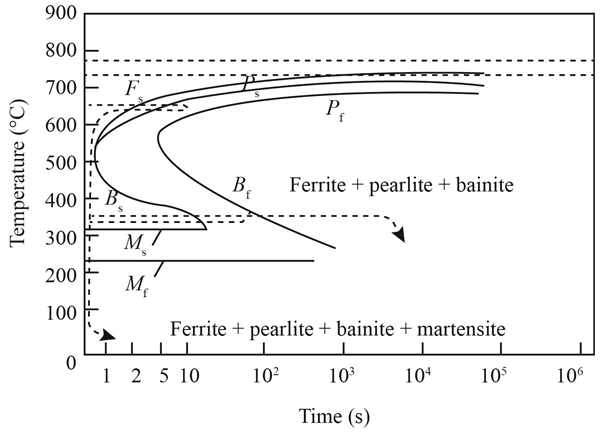

(b)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to yy

3) Step3: Quench again it toyyy

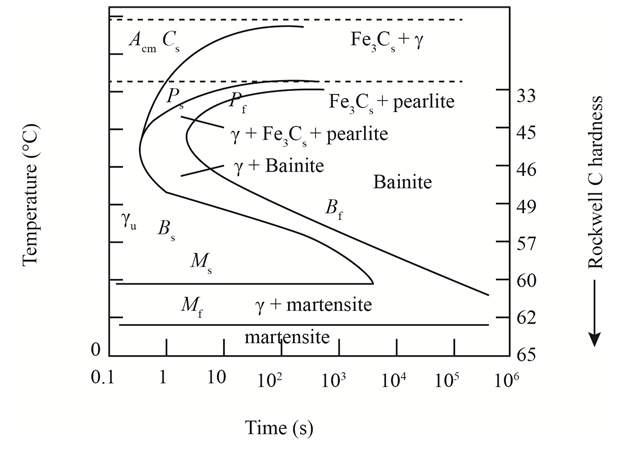

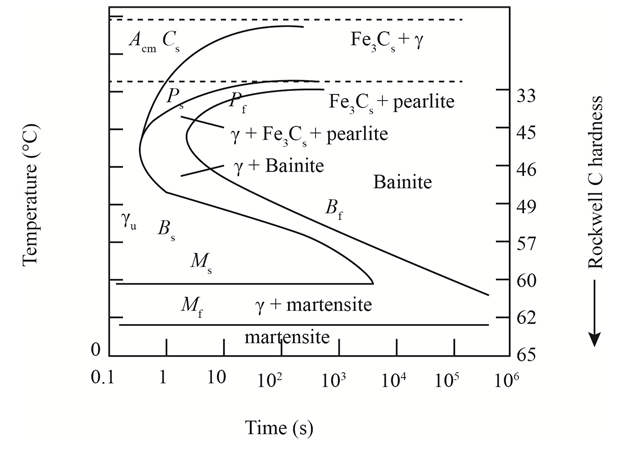

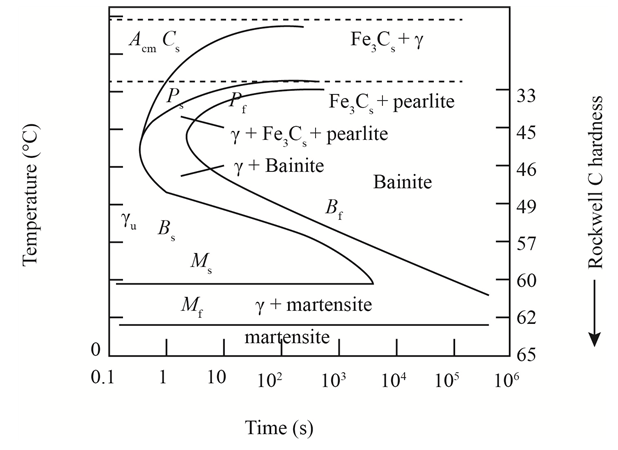

(c)

Interpretation:

The heat treatment for yyyyy

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

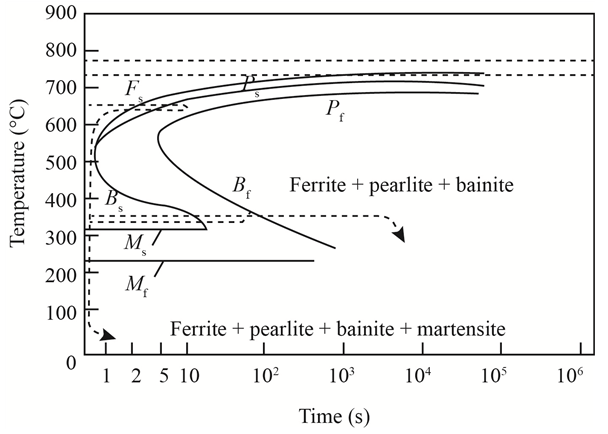

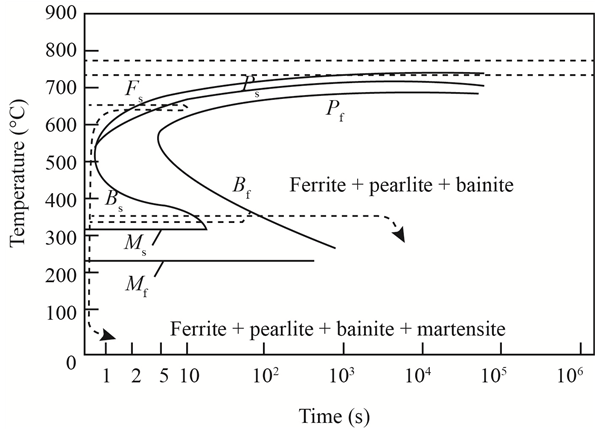

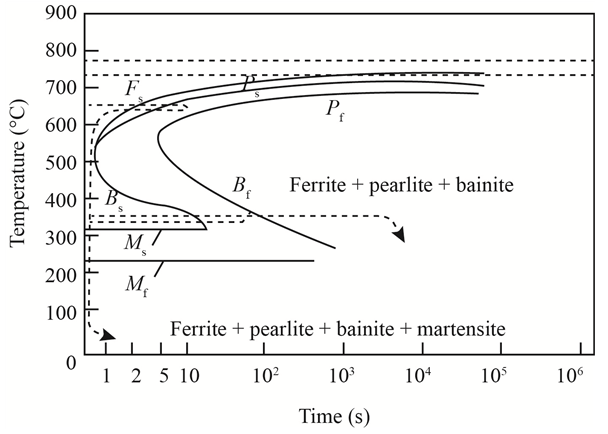

(d)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed 1050 steel with HRC 40 is:-

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(e)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed 10110 steel with HRC 55is:-

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(f)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

Want to see more full solutions like this?

Chapter 13 Solutions

Essentials Of Materials Science And Engineering

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY