(a)

Interpretation:

The phases formed for the condition of oil (without agitation), when a bar of 1080 steel is quenched above eutectoid temperature should be determined.

Concept introduction:

Phase is defined as the homogeneous portion of the system having same physical and chemical characteristics.

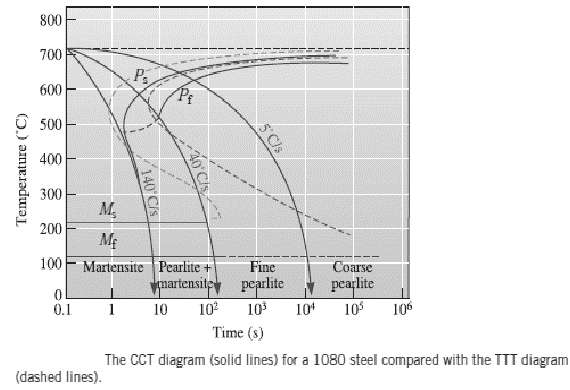

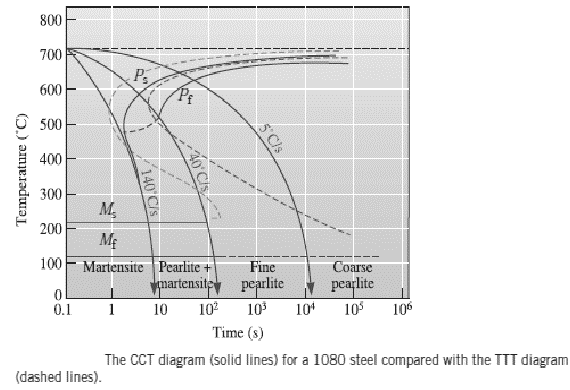

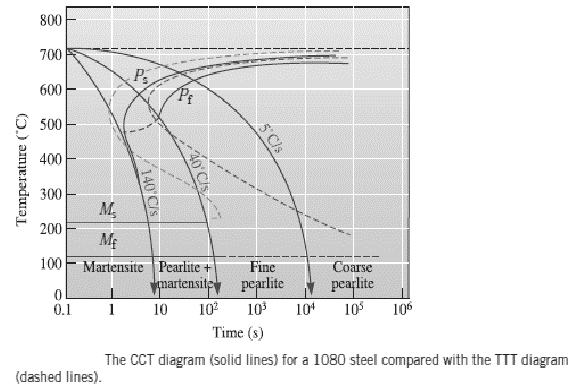

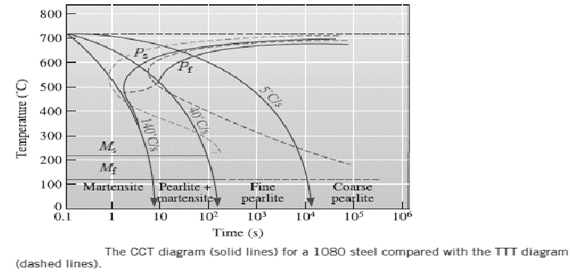

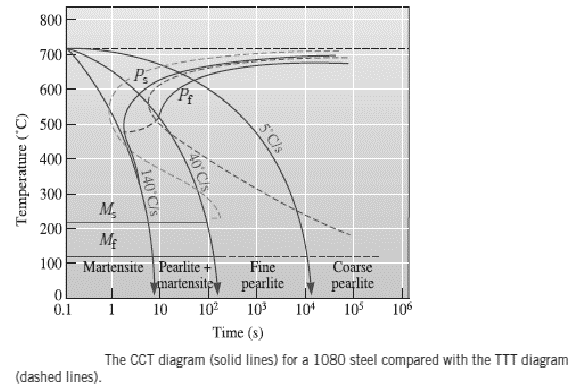

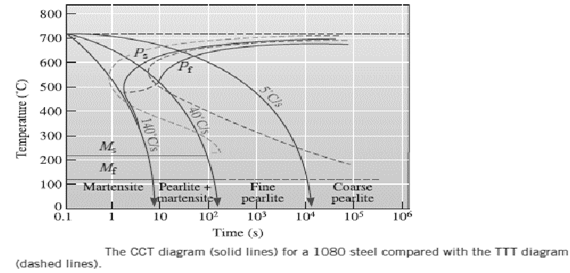

Continuous cooling transformation (CCT) is used to determine the microstructure produced in the steel at various rates of cooling. In CTT diagram no region for bainite is observed. CTT curve for 1080 steel is shown below:

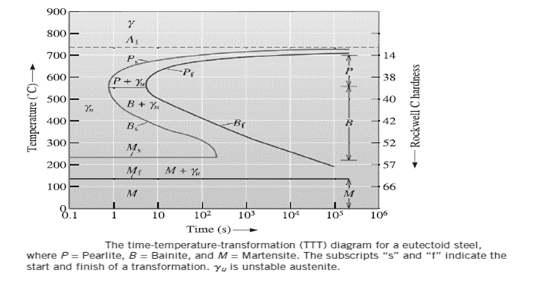

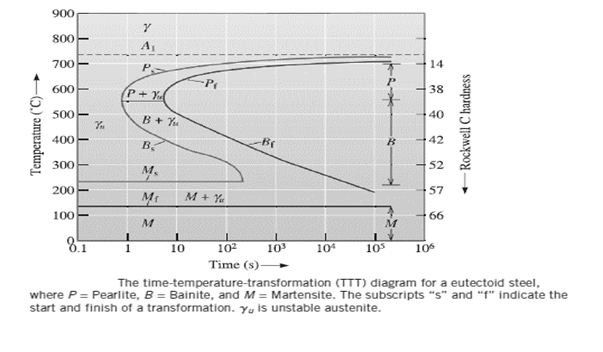

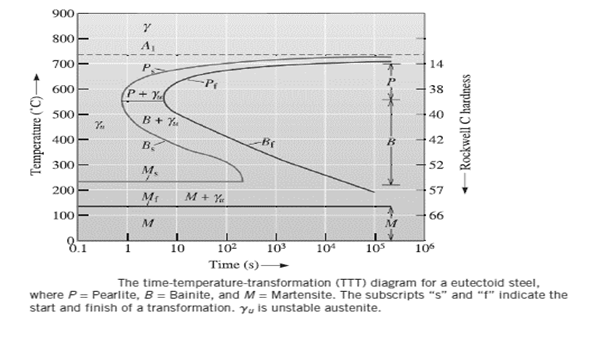

TTT diagram is time temperature transformation diagram which shows the transformation occurring in the material at a given temperature as a function of time.

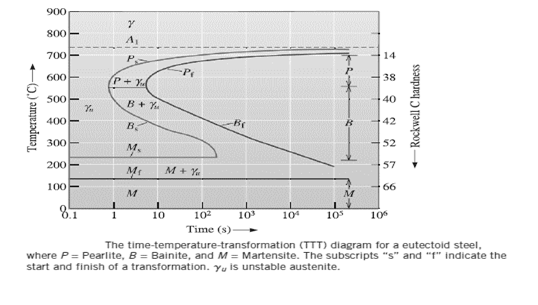

The TTT diagram for eutectoid steel is shown below:

The graph shows the relationship at which the transformation occurs at a given temperature with respect to hardness of material with respect to time.

Answer to Problem 13.26P

The required value of phase considering the condition of oil (without agitation) is fine pearlite.

Explanation of Solution

Given information:

Continuous cooling transformation curve for 1080 steel is shown below:

Based on given information, using graph to determine the phase,

For the given condition of oil without agitation, the value of temperature considered is

When the cooling of steel 1080 at the temperature of

The required value of phase considering the condition of oil (without agitation) is fine pearlite.

In order to obtain coarser pearlite, the required cooling rate should be less than

(b)

Interpretation:

The phases formed for the condition of oil (agitation), when a bar of 1080 steel is quenched above eutectoid temperature should be determined.

Concept introduction:

Phase is defined as the homogeneous portion of the system having same physical and chemical characteristics.

Continuous cooling transformation (CCT) is used to determine the microstructure produced in the steel at various rates of cooling. In CTT diagram no region for bainite is observed. CTT curve for 1080 steel is shown below:

TTT diagram is time temperature transformation diagram which shows the transformation occurring in the material at a given temperature as a function of time.

The TTT diagram for eutectoid steel is shown below:

The graph shows the relationship at which the transformation occurs at a given temperature with respect to hardness of material with respect to time.

Answer to Problem 13.26P

The required value of phase considering the condition of oil (agitation) is pearlite with martensite.

Explanation of Solution

Based on given information, using graph to determine the phase,

For the given condition of oil without agitation, the value of temperature considered is

When the cooling of steel 1080 at the temperature of

The required value of phase considering the condition of oil (agitation) is pearlite with martensite.

In order to obtain coarser pearlite, the required cooling rate should be less than

(c)

Interpretation:

The phases formed for the condition of oil (agitation), when a bar of 1080 steel is quenched above eutectoid temperature should be determined.

Concept introduction:

Phase is defined as the homogeneous portion of the system having same physical and chemical characteristics.

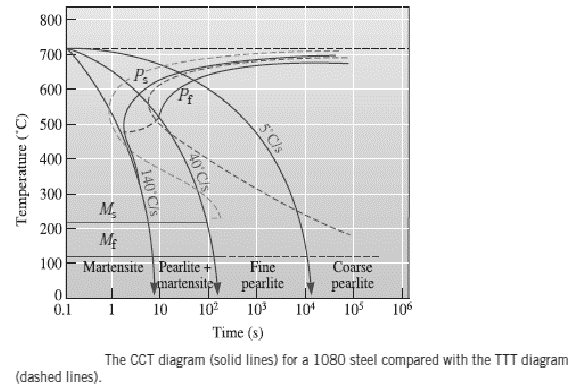

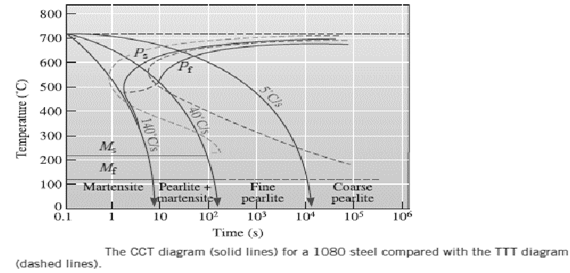

Continuous cooling transformation (CCT) is used to determine the microstructure produced in the steel at various rates of cooling. In CTT diagram no region for bainite is observed. CTT curve for 1080 steel is shown below:

TTT diagram is time temperature transformation diagram which shows the transformation occurring in the material at a given temperature as a function of time.

The TTT diagram for eutectoid steel is shown below:

The graph shows the relationship at which the transformation occurs at a given temperature with respect to hardness of material with respect to time.

Answer to Problem 13.26P

The required value of phase considering the condition of water(agitation) is Martensite.

Explanation of Solution

Based on given information, using graph to determine the phase,

For the given condition of oil without agitation, the value of temperature considered is

When the cooling of steel 1080 at the temperature of

The required value of phase considering the condition of water(agitation) is Martensite.

In order to obtain coarser pearlite, the required cooling rate should be less than

(d)

Interpretation:

The phases formed for the condition of Brine(no agitation), when a bar of 1080 steel is quenched above eutectoid temperature should be determined.

Concept introduction:

Phase is defined as the homogeneous portion of the system having same physical and chemical characteristics.

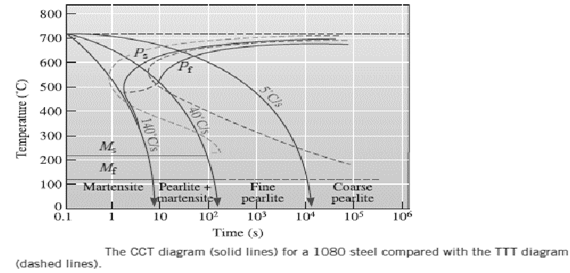

Continuous cooling transformation (CCT) is used to determine the microstructure produced in the steel at various rates of cooling. In CTT diagram no region for bainite is observed. CTT curve for 1080 steel is shown below:

TTT diagram is time temperature transformation diagram which shows the transformation occurring in the material at a given temperature as a function of time.

The TTT diagram for eutectoid steel is shown below:

The graph shows the relationship at which the transformation occurs at a given temperature with respect to hardness of material with respect to time.

Answer to Problem 13.26P

The required value of phase considering the condition of Brine(no agitation) is pearlite with martensite.

Explanation of Solution

Based on given information, using graph to determine the phase,

For the given condition of oil without agitation, the value of temperature considered is

When the cooling of steel 1080 at the temperature of

The required value of phase considering the condition of Brine(no agitation) is Martensite with pearlite.

In order to obtain coarser pearlite, the required cooling rate should be less than

Want to see more full solutions like this?

Chapter 13 Solutions

Essentials Of Materials Science And Engineering

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY