(a)

The phases present and the weight fraction of each phase after the procedure.

(a)

Answer to Problem 5.17P

The phases present is

Explanation of Solution

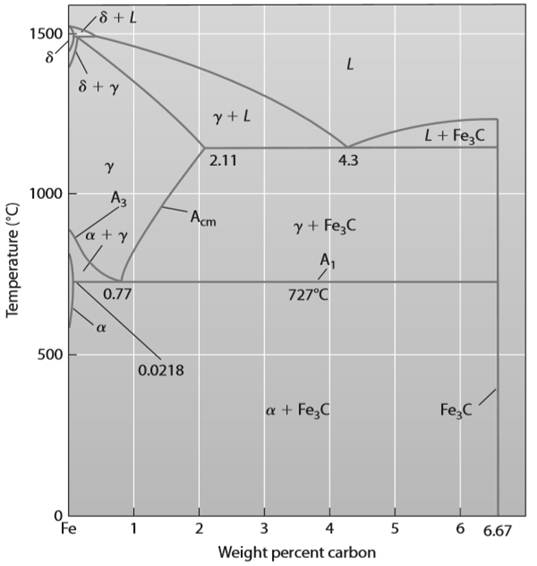

Draw the phase diagram for Iron carbon alloy as shown below:

Refer to Above figure; when

At

Write the expression for weight fraction of

Here,

Write the expression weight fraction for

Here,

Calculation:

Substitute

Substitute

Thus, the phases present is

(b)

The approximate weight fraction of alloy in proeutectoid

(b)

Answer to Problem 5.17P

The approximate weight fraction of alloy in proeutectoid

Explanation of Solution

Refer to the phase diagram of iron-carbon alloy the chemical composition of

Write the expression for weight fraction of

Here,

Write the expression weight fraction for Pearlite phase by lever rule.

Here,

Calculation:

Substitute

Substitute

Thus, the approximate weight fraction of alloy in proeutectoid

Want to see more full solutions like this?

Chapter 5 Solutions

Materials Science And Engineering Properties

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning