Concept explainers

(a)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(a)

Explanation of Solution

Given:

The inlet mass

The inlet pressure

The inlet temperature

The mass flow rate

The pressure at exit

The moisture content

Calculation:

Initially find out the properties of the geothermal water.

At state 1:

The geothermal water is extracted at the state of saturated liquid at the temperature of

The enthalpy at state 1 is as follows.

Refer Table A-4, “Saturated water-Temperature table”

The enthalpy

Refer Table A-1, “Molar mass, gas constant, and critical-point properties”.

At state 2:

The exit pressure of the flash chamber is

The geothermal steam is flashed at constant enthalpy. The exit steam of the flash chamber is at the quality of

Here, the fluid enthalpy is

Substitute

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 4:

The steam is at the state of saturated mixture at the pressure of

The quality at state 4 is as follows.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Write the formula for mass flow rate of vapor at entering the turbine.

Substitute

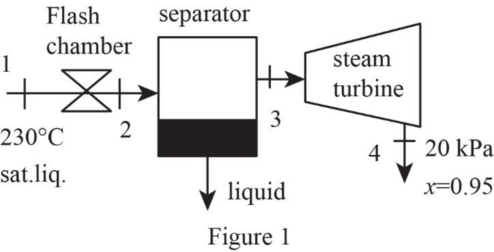

Draw schematic diagram of single flash geothermal power plant as shown in Figure 1.

Write the general energy rate balance equation.

Here, the rate of total energy in is

Consider the system operates at steady state. Hence, the rate of change in net energy of the system becomes zero.

The Equation (I) is reduced as follows.

Refer Figure 1.

The flash chamber is nothing but the expansion valve. At expansion valve, the enthalpy kept constant.

Express the energy balance equation for the flash chamber.

Express the energy balance equation for the separator.

Express the energy balance equation for the turbine.

Substitute

Equation (III).

Thus, the power output turbine is

(b)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(b)

Explanation of Solution

Similarly for the pressure

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

Calculation:

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

(c)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(c)

Explanation of Solution

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

(d)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(d)

Explanation of Solution

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

Want to see more full solutions like this?

Chapter 6 Solutions

Fundamentals of Thermal-Fluid Sciences

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY