Concept explainers

a)

To determine: The process capacity of dolls per hour with a batch size of 500 dolls.

a)

Explanation of Solution

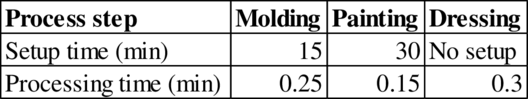

Given information:

Capacity of Molding:

Capacity of painting:

Capacity of dressing:

The capacity of dressing is the lowest of all. Hence, it will be the capacity of the process.

The capacity of the process is 200 units per hour.

b)

To determine: The utilization of depositing for 800 dolls.

b)

Explanation of Solution

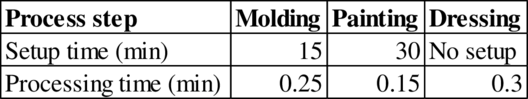

Given information:

Capacity of Molding:

Capacity of painting:

Capacity of dressing:

Calculation of utilization of molding:

The flow rate is the minimum demand and process capacity. The capacity of the process is 200 units per hour. The demand is 4,000 dolls in 40 work hours which gives 100 dolls per hour. Therefore, the number of dolls per minute will be:

The flow rate is 1.67 dolls per minute.

Calculation of utilization:

The utilization of molding is 41.75%.

c)

To determine: The determine the batch size that would minimize the inventory without decreasing the flow rate.

c)

Explanation of Solution

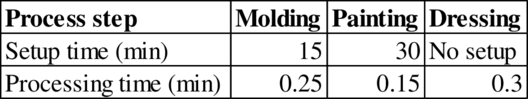

Given information:

Calculation of batch size for molding:

Calculation of batch size for painting:

The batch size is 300 units.

d)

To determine: The determine the batch size that would minimize the inventory without decreasing the flow rate.

d)

Explanation of Solution

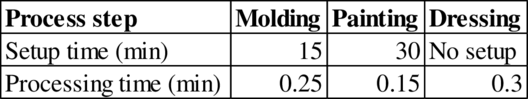

Given information:

Calculation of batch size for molding:

Calculation of batch size for painting:

The batch size is 67 units.

Want to see more full solutions like this?

Chapter 7 Solutions

Operations Management With Connect

- A final assembly plant for a certain automobile model is to have a capacity of 240,000 units annually. The plant will operate 50 weeks/yr, two shifts/day, 5 days/week, and 8.0 hours/shift. It will be divided into three departments: (1) Body shop, (2) paint shop, (3) trim-chassis-final department. The body shop welds the car bodies using robots, and the paint shop coats the bodies. Both of these departments are highly automated. Trim-chassis-final has no automation. There are 15.5 hours of direct labor content on each car in this department, where cars are moved by a continuous conveyor. Determine: (a) Hourly production rate of the plant, (b) number of workers and workstations required in trim-chassis-final if no automated stations are used, the average manning level is 2.5, balancing efficiency = 93%, proportion uptime = 95%, and a repositioning time of 0.15 min is allowed for each worker.arrow_forwardPickson Luthiers Corporation makes four models of electric guitars, ScarCT, Dela Mort, Warax, and Invazen. Each guitar must flow through five departments, assembly, painting, sound testing, inspection, and packaging. The table below shows the relevant data. Production rates are shown in units/hour. (ScarCT is assembled elsewhere). Pickson wants to determine how many guitars to make to maximize monthly profit. Pickson Luthiers Corporation Data Guitar Model Selling price/Unit Variable cost/Unit Min Sales Max Sales ScarCT 750.00 660.00 0 2500 Dela Mort 788.00 680.00 0 2000 Warax 800.00 700.00 100 1000 Invazen 850.00 800.00 80 500 Production rates (units/hour) ScarCT Dela Mort Warax Invazen Hours Available Assembly - 35 25 20 220 Painting 35 20 15 10 220 Sound Testing 20 10 20 18 220 Inspection 10 12 8 5 220 Packaging 9 10 5 8 220 Use a linear optimization model based on the data to answer the following…arrow_forwardYou operate a process with three workstations; the cycle times are given below. A regular batch is 52 units and your production line runs 5 hours per day. Calculate how many hours lead time is required to ship a batch, assuming there are no orders ahead in the queue and there is no inventory to fill the order. Workstation 1 has a cycle time of 2 minutes per unit Workstation 2 has a cycle time of 3 minutes per unit Workstation 3 has a cycle time of 3 minutes per unit Select one: a. 1560.00 b. 8.00 c. 1560.00 d. 90.00 e. 2340.00arrow_forward

- A small shoe manufacturer makes two styles of shoes: oxfords and loafers. Two machines are used in the process: a cutting machine and a sewing machine. Each type of shoe requires 15 min per pair on the cutting machine. Oxfords require 10 min of sewing per pair, and loafers require 20 min of sewing per pair. Because the manufacturer can hire only one operator for each machine, each process is available for just 8 hours a day. Set up a system of linear inequalities that describes the number of pairs of each style of shoes that the manufacturer can produce within required working hours.arrow_forwardA bank recently finished construction of a new building in the downtown business district. You have been asked to help them arrange the various departments of its check processing division to minimize the workflow (Summation LxD) in its operations. The movement of checks between departments is shown in the table below. Department 4 (the check distribution department) must be in the room with the elevator. Only lateral movement is allowed (no diagonal movement allowed) from the center of one department to the center of the destination department. Each department is 50 feet x 50 feet. What is the Summation LxD of the recommended layout? 10,640 feet 15,960 feet 26,600 feet 38,800 feet None of the above Which of the potential layouts shown above should be recommended to the bank management? (Below is the potential layouts) Layout A Layout B Layout C Layout D None of the abovearrow_forwardA company is in the business of machining parts that go through various work centers. Suppose work center A feeds work center B with parts. The following times (in minutes) are given for each work center. Work Center Setup time Run time (per part) Move time A 3 0.5 6 B 2 0.1 8 A standard kanban container holds 50 parts that are transferred from work center A to work center B. The demand rate at work center B is four parts per minute. How many kanban containers are needed for this situation? 2. If move time is cut in half, what does this do to the number of containers needed? How much will this change reduce inventory?arrow_forward

- Roedel Electronics produces tablet computer accessories, including integrated keyboard tablet stands that connect a keyboard to a tablet device and hold the device at a preferred angle for easy viewing and typing. Roedel produces two different sizes of integrated keyboard tablet stands, small and large. Each size uses the same keyboard attachment, but the stand consists of two different pieces, a top flap and a vertical stand that differ by size. Thus, a completed integrated keyboard tablet stand consists of three subassemblies that are manufactured by Roedel: a keyboard, a top flap and a vertical stand. Roedel's sales forecast indicates that 7,000 small integrated keyboard tablet stands and 5,000 large integrated keyboard tablet stands will be needed to satisfy demand during the upcoming Christmas season. Because only 500 hours of in-house manufacturing time are available, Roedel is considering purchasing some, or all, of the subassemblies from outside suppliers. If Roedel…arrow_forwardRoedel Electronics produces tablet computer accessories, including integrated keyboard tablet stands that connect a keyboard to a tablet device and hold the device at a preferred angle for easy viewing and typing. Roedel produces two different sizes of integrated keyboard tablet stands, small and large. Each size uses the same keyboard attachment, but the stand consists of two different pieces, a top flap and a vertical stand that differ by size. Thus, a completed integrated keyboard tablet stand consists of three subassemblies that are manufactured by Roedel: a keyboard, a top flap and a vertical stand. Roedel's sales forecast indicates that 7,000 small integrated keyboard tablet stands and 5,000 large integrated keyboard tablet stands will be needed to satisfy demand during the upcoming Christmas season. Because only 500 hours of in-house manufacturing time are available, Roedel is considering purchasing some, or all, of the subassemblies from outside suppliers. If Roedel…arrow_forwardRoedel Electronics produces tablet computer accessories, including integrated keyboard tablet stands that connect a keyboard to a tablet device and hold the device at a preferred angle for easy viewing and typing. Roedel produces two different sizes of integrated keyboard tablet stands, small and large. Each size uses the same keyboard attachment, but the stand consists of two different pieces, a top flap and a vertical stand that differ by size. Thus, a completed integrated keyboard tablet stand consists of three subassemblies that are manufactured by Roedel: a keyboard, a top flap and a vertical stand. Roedel's sales forecast indicates that 7,000 small integrated keyboard tablet stands and 5,000 large integrated keyboard tablet stands will be needed to satisfy demand during the upcoming Christmas season. Because only 500 hours of in-house manufacturing time are available, Roedel is considering purchasing some, or all, of the subassemblies from outside suppliers. If Roedel…arrow_forward

- What is the drum, buffer and rope concept that comes from the theory of constraint? (Eli goldratt)arrow_forwardThe Sure To Peal Paint Company stores all its metal compressed gas containers in a warehouse. These long cylindrical metal tanks contain various gases used in manufacturing cans of spray paint. The gas tanks are delivered to the warehouse by truck. Two receiving dock workers unload the containers from the delivery trucks and place them on four wheel trucks. Two materials handlers are responsible for pushing the loaded trucks into the warehouse, unloading the tanks and setting them up on end. The two materials handlers spend a major portion of their day moving loads of the gas tanks into the warehouse and placing them into the proper storage locations. In total, there are five different types of gases that in equal proportion make up 98% of all gas handled. Question: Management would like to identify a better way to handle these gas tanks. How can the handling operation be improved?arrow_forwardA production line is a set of sequential operations established in a factory plant where components are assembled to make a finished product or where materials are put through a refining process to produce an end-product that is suitable for onward consumption. Ford have seven production lines in their manufacturing plant for their automotive parts where each production line produces 120, 100, 80, 116, 77, 94, 112 output per day. (a) As the Production Manager at Ford, you are required to submit the daily report of the production plant. Calculate the mean, median, and mode from the data based on the output that has been provided. (b) Also calculate the three critical parameters for measuring spread in the following ways: Range Variance Standard Deviationarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,