(a)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

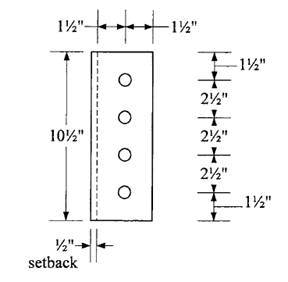

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location. Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

Yielding:

Rupture:

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

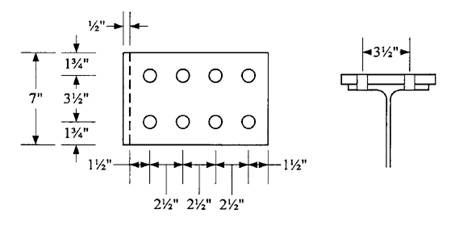

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

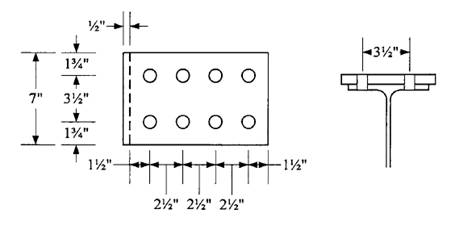

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

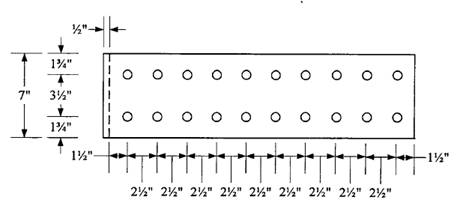

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

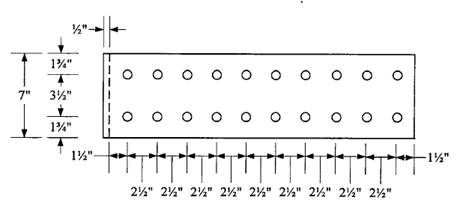

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

(b)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

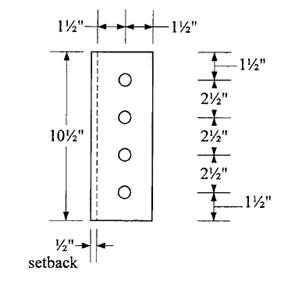

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location.

Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes.

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

The allowable shear yield strength per unit length is

The base metal allowable shear rupture strength per unit length is

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

Want to see more full solutions like this?

Chapter 8 Solutions

Steel Design (Activate Learning with these NEW titles from Engineering!)

- Select an American Standard Channel shape for the following tensile loads: dead load = 54 kips, live load = 80 kips, and wind load = 75 kips. The connection will be with longitudinal welds. Use an estimated shear lag factor of U = 0.85. (In a practical design, once the member was selected and the connection designed, the value of U would be computed and the member design could be revised if necessary.) The length is 17.5 ft. Use Fy=50 ksi and Fu=65 ksi. a. Use LRFD. b. Use ASD.arrow_forward5. Determine the size of the fillet weld required for the shear and tension connection if p = 200KN, 5 = 150mm, b = 150mm and d = 20mm. Use E70 electrodes and assume the column and bracket plate does not control the strength. Steel Column Bracket (out from resection UNMA COCarrow_forwardA beam is connected to a column with 7/8-inch-diameter, A325N bearing-type bolts, as shown in the figure. Eight bolts connect the tee to the column. A992 steel is used. Assume that this connection was to be made into a moment connection by bringing the flanges of the beam tight to the column flange, then providing fillet welds (E70) on both sides of each beam flange to the column flange. Ignore the small length that the web of the beam is in the way and thus prevents a full fillet weld on the one side of each flange. Using the maximum fillet weld size recommended, can a moment connection be made that is adequate if it is required to resist 75% of the φMp capacity of the beam? Do not worry about checking the shear connection with the WT again and also assume that the WT connection provides no rotational resistance to the moment connectionarrow_forward

- Determine the maximum service load P (ASD) that the connection can resist. Use 27 mm Ø A490-N bolts, and 10 mm A-36 plate and a load P with a slope 1H: 2V. Assume that edge distance and bolt spacing are not critical. ***Note: Lod P is acting at a slope of 1H: 2Varrow_forwardThe billboard post support a 5KN dead load as shown. The cantilever beam and the brace is pinnedconnected to the post. Assume that the connections along the cap and the cap plate is adequate, as well asthe gusset plate and the cap plate. Use LRFD design considerations.a.) Determine the ultimate tensile force the brace carries. b.) Determine the adequacy of Connection 1 the bolt where 2- 16mm Ø A325 hex bolt and the plateswhere A36 steel. c.) If the connection at Connection 1 will be a welded connection what will be the adequate thickness ofthe weld. Note that the welds are only applied at the sides of the cap plate. Use electrode 70 for theweld. d.) Determine the adequacy of the connection due to shear and tension in Connection 2 if the bolts were4- 12mm Ø A325 hex bolt.arrow_forwardRepeat Prob. 14-1 if the weld lengths are 24 in. Prob. 14-1: A 1/4-in fillet weld, SMAW process, is used to connect the members shown in the accompanying illustration. Determine the LRFD design load and the ASD allowable load that can be applied to this connection, including the plates, using the AISC Specification and E70 electrodes.arrow_forward

- Design for a tension member and its bolt connection basedon the following conditions below: a. Tension member: Single Angle Bar with a grade of A36 and a length of 8.08m b. Service tension load: 1323 with a dead-to-live-to-wind ratio of 10:20:3 c. Group A bolts and must not permit slip d. Connected to a 10-mm-thick A36 gusset plate A complete sketch showing all necessary information for the said connection is needed. Design this oneusing LRFD and ASD method.arrow_forwardDetermine the capacity of the details shown below. A992: Fy=50ksi, Fu=65ksiA36: Fy=36ksi, Fu=58ksieffective bolt hole diameter = bolt hole + 1/16"beam properties: tw=0.38 in., bf=7.07 in., tf=0.63 in.Fexx=70ksi i) what is the weld capacity of the shear connection in kips? (2 decimal places)arrow_forwardUse LRFD and select an American Standard Channel shape for the following tensile loads: dead load = 54kN , live load = 80 kN, and wind load = 75 kN. The connection will be with two 9 inches long longitudinal welds.Use an estimated shear lag factor of U = 0.85. Once the member has been selected, compute the actual value of U and revise the design if necessary. The length is 17.5ft. Use AISC Manual.arrow_forward

- i) what is the weld capacity of the shear connection in kips? (2 decimal places)A992: Fy=50ksi, Fu=65ksiA36: Fy=36ksi, Fu=58ksieffective bolt hole diameter = bolt hole + 1/16"beam properties: tw=0.38 in., bf=7.07 in., tf=0.63 in.Fexx=70ksiarrow_forwardRepeat Prob. 15-11 using SMAW shop and field welds Prob. 15-11: Select a framed beam connection, using LRFD and ASD, for a W33 x 130 beam (A992 steel) with a dead load reaction = 45 k and a live load reaction = 65 k. It is to be connected to the flange of a W36 x 150 column.The A36 web angles are to be welded with E70 electrodes (weld A in the Manual) and are to be field-connected to the girder with 3/4-in A325-N bolts.arrow_forwardThe connection consists of a plate connected by a five 25-mm diameter rivets. It carries a load P=120 kN.arrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning