Concept explainers

Question:

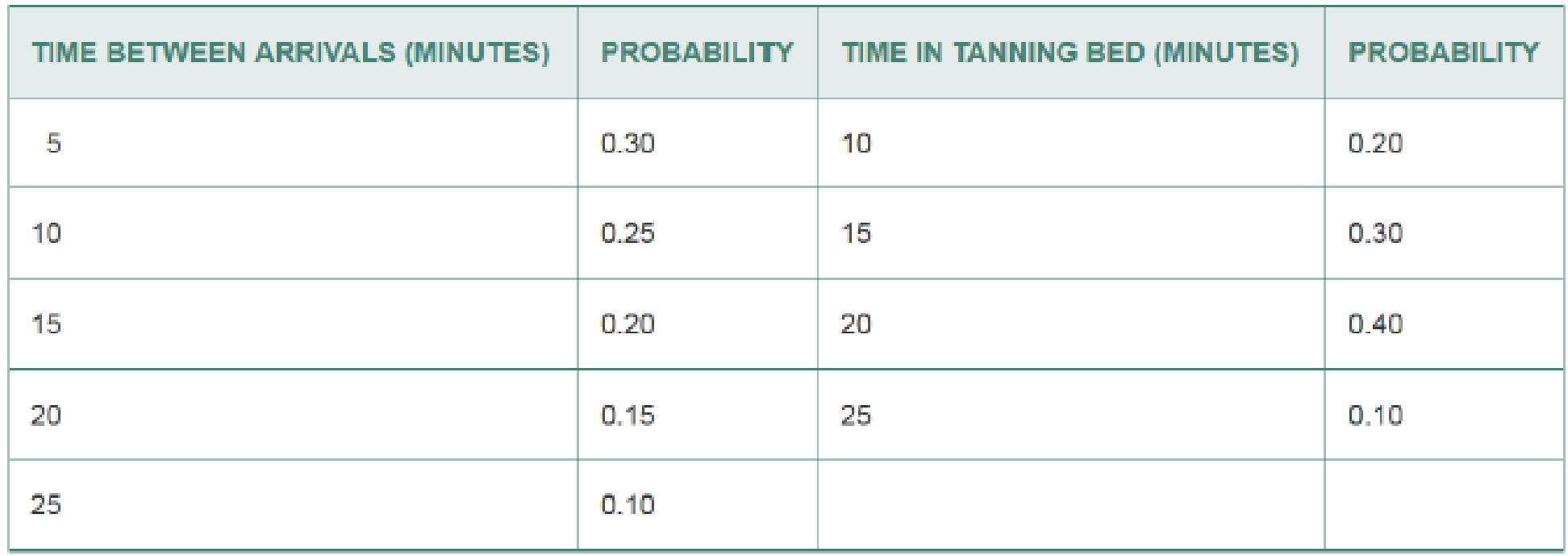

• • • F.15 Connecticut Tanning has two tanning beds. One bed serves the company’s regular members exclusively. The second bed serves strictly walk-in customers (those without appointments) on a first-come, first-served basis. Orv karan, the store manager, has noticed on several occasions during the busy 5 hours of the day (2:00 p.m. until 7:00 p.m.) that potential walk-in customers will most often walk away from the store if they see one person already waiting for the second bed. He wonders if capturing this lost demand would justify adding a third bed. Leasing and maintaining a tanning bed costs Connecticut Tanning $600 per month. The price paid per customer varies according to the time in the bed, but Orv has calculated the average net income for every 10 minutes of tanning time to be $2. A study of the pattern of arrivals during the busy hours and the time spent tanning has revealed the following:

- a. Simulate 4 hours of operation (arrivals over 4 hours). Use the 14th column of Table F.4 (p. 785) for arrival times and the 8th column for tanning times. Assume there is one person who has just entered the bed at 2:00 p.m. for a 20-minute tan. Indicate which customers balk at waiting for the bed to become available. How many customers were lost over the 4 hours?

- b. If the store is open an average of 24 days a month, will capturing all lost sales justify adding a new tanning bed?

Want to see the full answer?

Check out a sample textbook solution

Chapter F Solutions

Operations Management-With Myomlab Access

- Question : One way for a manager of a property to increase the net operating income of a retail store is to increase the flow of customer traffic into the store. If the increased traffic results in increased sales, then the net operating income of the store will increase. If this can be sustained then the manager has increased the value of the property. True or Falsearrow_forwardquestion 7 You manage an ice cream factory that makes two flavors: Creamy Vanilla and Continental Mocha. Into each quart of Creamy Vanilla go 2 eggs and 3 cups of cream. Into each quart of Continental Mocha go 1 egg and 3 cups of cream. You have in stock 450 eggs and 750 cups of cream. You make a profit of $3 on each quart of Creamy Vanilla and $2 on each quart of Continental Mocha. How many quarts of each flavor should you make to earn the largest profit? HINT [See Example 2.] (If an answer does not exist, enter DNE.) Creamy Vanilla quartsContinental Mocha quartsarrow_forwardQuestion 5The management of CDC Construction Pioneers have decided to build 900 new apartments in the Kasoa area due to the influx of immigrant workers into the country. Two Architectural Companies have provided building plans and technical schematics for the project. Management are happy with the proposals of both Standard apartment and Deluxe apartment. After investigating the steps involved in construction, management determined that each apartment complex built will require some resources. Management analysed each of the bids and concluded that if the plans of Standard apartment are built, it requires 0.7 days in foundation works, 0.5 days in the masonry, 1 day in finishing, and 0.1 days in painting works. Deluxe apartment will require 1 day in foundation works, 0.83 days in the masonry, 0.67 days in finishing, and 0.25 days in the painting works. Management estimate that, 630 days for foundation works, 600 days for masonry, 708 days for finishing and 135 days for 11painting works…arrow_forward

- Question 5 AIT computer department purchases a new computer every two years with preferences for three models; T1, T2 and T3. If the present model is T1, the next computer may be T2 with probability 0.2 or T3 with probability 0.15. If the present model is T2, the probabilities of switching to T1 and T3 are 0.6 and 0.25 respectively. And if present model is T3 then, the probabilities of switching to T1 and T2 are 0.5 and 0.1 respectively. Represent the situation as a Markov chain.arrow_forwardOperation Research Question QUESTION TWO a) Simulation techniques have been used to analyze problems of two distinct types: Practical real-life problems and theoretical problems related to basic sciences. Illustrate the statement giving examples of each type.arrow_forwardQuestion 2CWD Manufacturing makes three components for sale to refrigeration companies. Thecomponents are processed on two machines: a shaper and a grinder. The times (in minutes)required on each machine are as follows: Machine Component Shaper Grinder 1 6 4 2 4 5 3 4 2 The shaper is available for 120 hours, and the grinder is available for 110 hours. No more than200 units of component 3 can be sold, but up to 1000 units of each of the other components canbe sold. In fact, the company already has orders for 600 units of component 1 that must besatisfied. The profit contributions for components 1, 2, and 3 are $8, $6, and $9, respectively. (see image) If there are two possible answers one will suffice. Where necessary a range analysis must be shown.(convert to minutes)a) What is the optimal solution (in words)? b) An additional 4 hours of shaper time became available. Evaluate the effect? Explainc) Two hours of Grinder time was lost. Evaluate the effect? d) An additional…arrow_forward

- Question 2CWD Manufacturing makes three components for sale to refrigeration companies. Thecomponents are processed on two machines: a shaper and a grinder. The times (in minutes)required on each machine are as follows: Machine Component Shaper Grinder 1 6 4 2 4 5 3 4 2 The shaper is available for 120 hours, and the grinder is available for 110 hours. No more than200 units of component 3 can be sold, but up to 1000 units of each of the other components canbe sold. In fact, the company already has orders for 600 units of component 1 that must besatisfied. The profit contributions for components 1, 2, and 3 are $8, $6, and $9, respectively. (see image) If there are two possible answers one will suffice. Where necessary a range analysis must be shown.(convert to minutes)a) What is the optimal solution (in words)? b) An additional 4 hours of shaper time became available. Evaluate the effect? Explainc) Two hours of Grinder time was lost. Evaluate the effect? d) An additional…arrow_forwardQuestion Primer Inc. offers plumbing and air conditioning services to customers in Kumasi, Ghana. The company’s product strategy is to solve the customer’s problem irrespective of what it takes, at the time the customer needs it solved. The company provides same day service for customers, and theaim is to make the customer happy before leaving.The services of the company are available 24 hours a day, 7 days a week for customers. There is no extra charge for requests made on holidays, odd hours of the day, or in festive seasons. The company aims to be available at the call of customers without charging a pesewa extra, even at times when rival firms won’t get out of bed. The company fixes the price of the service before it begins, and customers can be assured of no extra charges. Irrespective of the customer’s location in the city, Primer Inc. does not charge additional fees for transportation. For all services, the company provides a one year guarantee on all parts and labour used,…arrow_forwardQuestion on that image attachedarrow_forward

- Question 2 A particular road is used by N drivers each day. Each driver obtains a benefit v from the journey and incurs a cost c(N ) that increases with the number of drivers on the road due to congestion. Suppose that the cost incurred is given by c(N) = a+bN, for some positive numbers a, b. If the agent decides not to use the road, they receive 0. You may assume throughout that the number of drivers N can be any real number (rather than an integer). Each driver uses the road at most once. the number of drivers that join the road is Ne = (v−a)/b (iv) Suppose that the government charges a toll t (a congestion charge) for each journey. Find the optimum toll. Interpret your answer in terms of the externality that each driver imposes on others.arrow_forwardWhich of the following is NOT responsible for health and safety at a construction worksite?Question 20 options: 1) Occupier of the worksite. 2) Person who installs machinery/equipment. 3) Self-employed person doing work at the workplace. 4) All of the above personnel are responsible for health and safety.arrow_forwardLast Question pls.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.