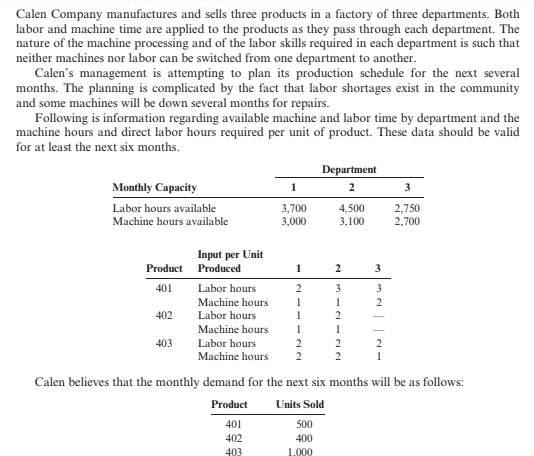

Calen Company manufactures and sells three products in a factory of three departments. Both labor and machine time are applied to the products as they pass through each department. The nature of the machine processing and of the labor skills required in each department is such that neither machines nor labor can be switched from one department to another. Calen's management is attempting to plan its production schedule for the next several months. The planning is complicated by the fact that labor shortages exist in the community and some machines will be down several months for repairs. Following is information regarding available machine and labor time by department and the machine hours and direct labor hours required per unit of product. These data should be valid for at least the next six months. Department Monthly Capacity 2 3 3,700 3,000 Labor hours available 4,500 3,100 2,750 2,700 Machine hours available Input per Unit Product Produced 1 2 3 401 Labor hours 2 3 3 Machine hours Labor hours 2 402 2 Machine hours 1 403 Labor hours 2 2 2 Machine hours 2 2 1 Calen believes that the monthly demand for the next six months will be as follows: Product Units Sold 401 500 402 400 403 1.000 Inventory levels will not be increased or decreased during the next six months. The unit cost and price data for each product are as follows: Product 401 402 403 Unit costs: Direct material $ 7 13 $17 Direct labor 66 38 51 Variable overhead 27 20 25 Fixed overhead 15 10 32 Variable selling 3 4 Total unit cost si18 83 $129 Unit selling price $196 S123 $167

Calen Company manufactures and sells three products in a factory of three departments. Both labor and machine time are applied to the products as they pass through each department. The nature of the machine processing and of the labor skills required in each department is such that neither machines nor labor can be switched from one department to another. Calen's management is attempting to plan its production schedule for the next several months. The planning is complicated by the fact that labor shortages exist in the community and some machines will be down several months for repairs. Following is information regarding available machine and labor time by department and the machine hours and direct labor hours required per unit of product. These data should be valid for at least the next six months. Department Monthly Capacity 2 3 3,700 3,000 Labor hours available 4,500 3,100 2,750 2,700 Machine hours available Input per Unit Product Produced 1 2 3 401 Labor hours 2 3 3 Machine hours Labor hours 2 402 2 Machine hours 1 403 Labor hours 2 2 2 Machine hours 2 2 1 Calen believes that the monthly demand for the next six months will be as follows: Product Units Sold 401 500 402 400 403 1.000 Inventory levels will not be increased or decreased during the next six months. The unit cost and price data for each product are as follows: Product 401 402 403 Unit costs: Direct material $ 7 13 $17 Direct labor 66 38 51 Variable overhead 27 20 25 Fixed overhead 15 10 32 Variable selling 3 4 Total unit cost si18 83 $129 Unit selling price $196 S123 $167

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter20: Inventory Management: Economic Order Quantity, Jit, And The Theory Of Constraints

Section: Chapter Questions

Problem 27P: Calen Company manufactures and sells three products in a factory of three departments. Both labor...

Related questions

Question

Required:

1. Calculate the monthly requirement for machine hours and direct labor hours for producing

Products 401, 402, and 403 to determine whether or not the factory can meet the monthly

sales demand.

2. Determine the quantities of 401, 402, and 403 that should be produced monthly to maximize

profits. Prepare a schedule that shows the contribution to profits of your product mix.

3. Assume that the machine hours available in Department 3 are 1,500 instead of 2,700. Calculate the optimal monthly product mix using the graphing approach to linear programming.

Prepare a schedule that shows the contribution to profits from this optimal mix. (CMA

adapted)

Transcribed Image Text:Calen Company manufactures and sells three products in a factory of three departments. Both

labor and machine time are applied to the products as they pass through each department. The

nature of the machine processing and of the labor skills required in each department is such that

neither machines nor labor can be switched from one department to another.

Calen's management is attempting to plan its production schedule for the next several

months. The planning is complicated by the fact that labor shortages exist in the community

and some machines will be down several months for repairs.

Following is information regarding available machine and labor time by department and the

machine hours and direct labor hours required per unit of product. These data should be valid

for at least the next six months.

Department

Monthly Capacity

2

3

3,700

3,000

Labor hours available

4,500

3,100

2,750

2,700

Machine hours available

Input per Unit

Product Produced

1

2

3

401

Labor hours

2

3

3

Machine hours

Labor hours

2

402

2

Machine hours

1

403

Labor hours

2

2

2

Machine hours

2

2

1

Calen believes that the monthly demand for the next six months will be as follows:

Product

Units Sold

401

500

402

400

403

1.000

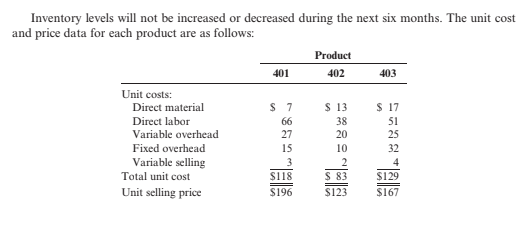

Transcribed Image Text:Inventory levels will not be increased or decreased during the next six months. The unit cost

and price data for each product are as follows:

Product

401

402

403

Unit costs:

Direct material

$ 7

13

$17

Direct labor

66

38

51

Variable overhead

27

20

25

Fixed overhead

15

10

32

Variable selling

3

4

Total unit cost

si18

83

$129

Unit selling price

$196

S123

$167

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 6 steps with 8 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,