Refer to print PR 23-1. The sequence of operations for this print is given below. Answer the questions following the sequence of operations. Sequence of operations onerator actuates the two push-button valves (1) and (2) until the weight starts to descend. lir passes through valves (1) and (2) to the time delay valve (3) and the pilot of valve (5). The four-way valve (5) is shifted, venting the head end of cylinder (4) and pressurizing the rod end. 4. The weight of the ram descends. The speed of descent is controlled by the exhaust control (7). The time delay valve (3) continues to time until the preset interval has passed. - The time delay valve (3) vents air pressure from the line between valve (2) and the pilot of valve (5). . With the pilot vented, the spring return of valve (5) shifts the valve to its normal position. O The rod end of cylinder (4) is vented and the head end is pressurized. 10. The weight ascends. 11. The speed of ascent is controlled by the exhaust control (6). Questions 8. What causes cylinder (4) to reverse? 9. What does the center line around valve (3) indicate? What component(s) are included? 10. Why is it not necessary to hold valves (1) and (2) down during the entire sequence? Unit 23 Instrumentation and Control Drawings 445 rch yPrint Ex 3) EXHAUST 2) MAN MAN Segu 4 AIR 9. (7) CLIPPARD MJV-2 12) 2-WAY PUSH-BUTTON VALVE 3) TIMAC AIR TIME DELAY VALVE TIMING RANGE .2-20 SECONDS MAC VAKVES INC. MODEL 71A-2-2 Queie AIRMATIC VALVE INC. 4) AIR CYLINDER MILLER FLUID POWER CO. MODEL 504, 1/4 NPT (5) 4-WAY 5-PORT SPRING RETURN VALVE LUB. 9. AIRMATIC VALVE INC. OR VERSA PRODUCTS CO. 67) EXHAUST CONTROL 8) SHUT OFF VALVE 9) FILTER-REGULATOR-LUBRICATOR COMBINATION WITH PRESSURE GAUGE. NORGREN FILT. PHOENIX PHOENIX, ARIZONA UNIDYNAMICS 8. A DIVISION OF UMC INDUSTRIES, INC. TOOL NAME PNEUMATIC CIRCUIT FOR DEAD WEIGHT PRESS SIZE CODE IDENT NO. DWG (TOOL) NO. 20-837 B 12079 Print supplied by Unidynar PR 23-1. Pneumatic Circuit for Dead Weight Press. Copyright Goodheart-Willcox Co., Inc. B.

Refer to print PR 23-1. The sequence of operations for this print is given below. Answer the questions following the sequence of operations. Sequence of operations onerator actuates the two push-button valves (1) and (2) until the weight starts to descend. lir passes through valves (1) and (2) to the time delay valve (3) and the pilot of valve (5). The four-way valve (5) is shifted, venting the head end of cylinder (4) and pressurizing the rod end. 4. The weight of the ram descends. The speed of descent is controlled by the exhaust control (7). The time delay valve (3) continues to time until the preset interval has passed. - The time delay valve (3) vents air pressure from the line between valve (2) and the pilot of valve (5). . With the pilot vented, the spring return of valve (5) shifts the valve to its normal position. O The rod end of cylinder (4) is vented and the head end is pressurized. 10. The weight ascends. 11. The speed of ascent is controlled by the exhaust control (6). Questions 8. What causes cylinder (4) to reverse? 9. What does the center line around valve (3) indicate? What component(s) are included? 10. Why is it not necessary to hold valves (1) and (2) down during the entire sequence? Unit 23 Instrumentation and Control Drawings 445 rch yPrint Ex 3) EXHAUST 2) MAN MAN Segu 4 AIR 9. (7) CLIPPARD MJV-2 12) 2-WAY PUSH-BUTTON VALVE 3) TIMAC AIR TIME DELAY VALVE TIMING RANGE .2-20 SECONDS MAC VAKVES INC. MODEL 71A-2-2 Queie AIRMATIC VALVE INC. 4) AIR CYLINDER MILLER FLUID POWER CO. MODEL 504, 1/4 NPT (5) 4-WAY 5-PORT SPRING RETURN VALVE LUB. 9. AIRMATIC VALVE INC. OR VERSA PRODUCTS CO. 67) EXHAUST CONTROL 8) SHUT OFF VALVE 9) FILTER-REGULATOR-LUBRICATOR COMBINATION WITH PRESSURE GAUGE. NORGREN FILT. PHOENIX PHOENIX, ARIZONA UNIDYNAMICS 8. A DIVISION OF UMC INDUSTRIES, INC. TOOL NAME PNEUMATIC CIRCUIT FOR DEAD WEIGHT PRESS SIZE CODE IDENT NO. DWG (TOOL) NO. 20-837 B 12079 Print supplied by Unidynar PR 23-1. Pneumatic Circuit for Dead Weight Press. Copyright Goodheart-Willcox Co., Inc. B.

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter8: Computer Numerical Control

Section8.6: Cnc Milling: Programming

Problem 9RQ: Write two blocks of code that could be used to start the spindle in a clockwise direction at 2200...

Related questions

Question

I need problem 8 answered pertaining to the print and sequence of operations that is both provided.

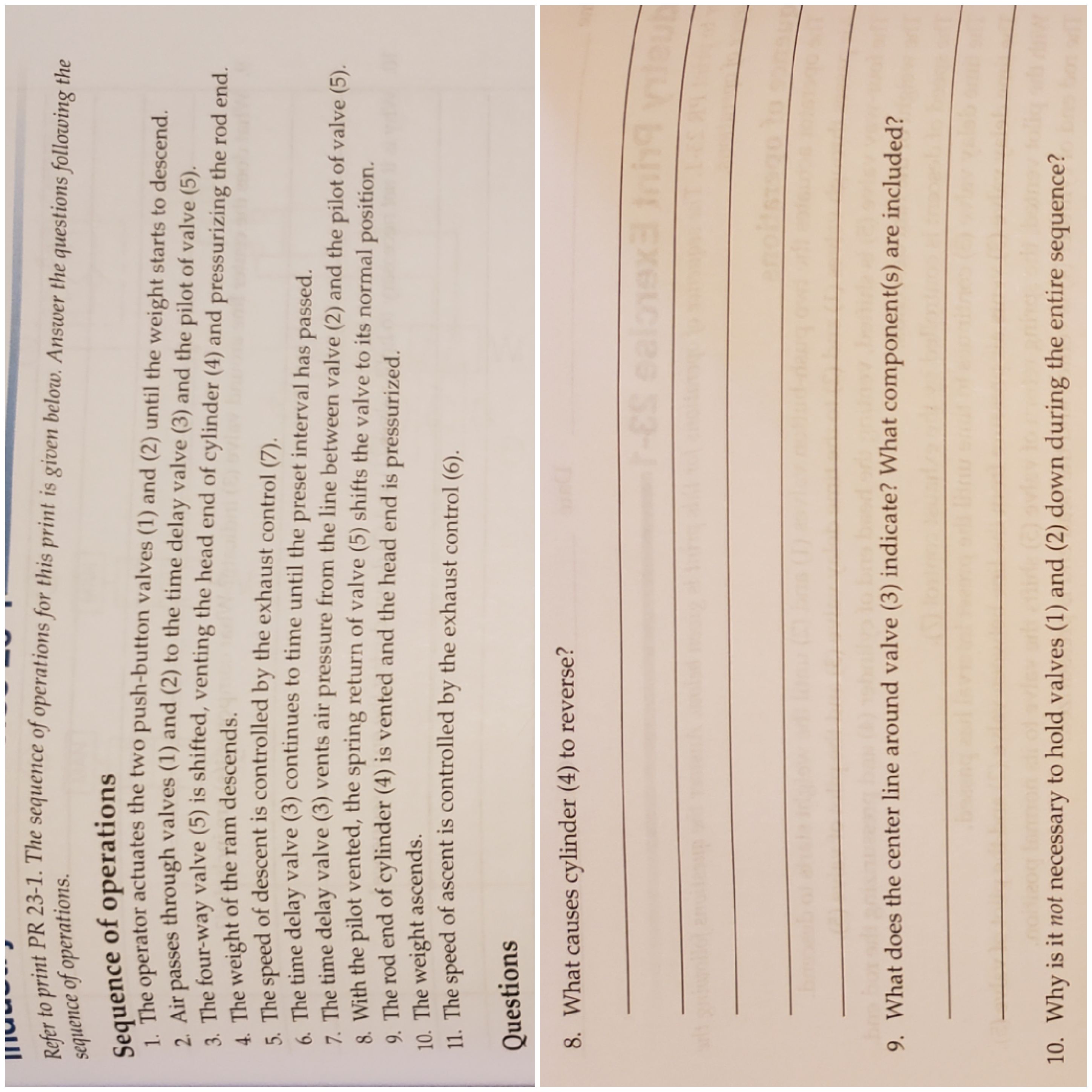

Transcribed Image Text:Refer to print PR 23-1. The sequence of operations for this print is given below. Answer the questions following the

sequence of operations.

Sequence of operations

onerator actuates the two push-button valves (1) and (2) until the weight starts to descend.

lir passes through valves (1) and (2) to the time delay valve (3) and the pilot of valve (5).

The four-way valve (5) is shifted, venting the head end of cylinder (4) and pressurizing the rod end.

4. The weight of the ram descends.

The speed of descent is controlled by the exhaust control (7).

The time delay valve (3) continues to time until the preset interval has passed.

- The time delay valve (3) vents air pressure from the line between valve (2) and the pilot of valve (5).

. With the pilot vented, the spring return of valve (5) shifts the valve to its normal position.

O The rod end of cylinder (4) is vented and the head end is pressurized.

10. The weight ascends.

11. The speed of ascent is controlled by the exhaust control (6).

Questions

8. What causes cylinder (4) to reverse?

9. What does the center line around valve (3) indicate? What component(s) are included?

10. Why is it not necessary to hold valves (1) and (2) down during the entire sequence?

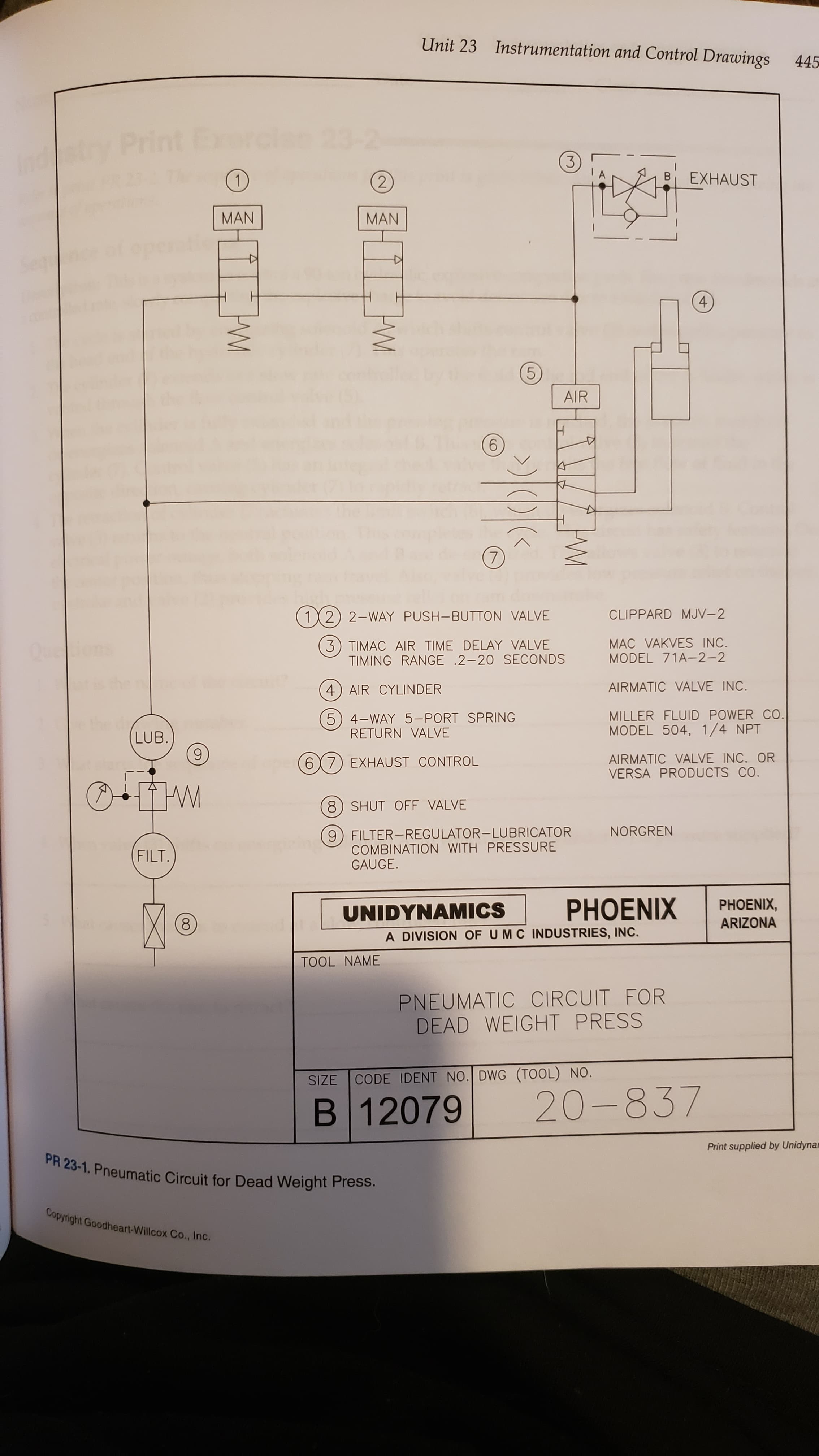

Transcribed Image Text:Unit 23

Instrumentation and Control Drawings

445

rch

yPrint Ex

3)

EXHAUST

2)

MAN

MAN

Segu

4

AIR

9.

(7)

CLIPPARD MJV-2

12) 2-WAY PUSH-BUTTON VALVE

3) TIMAC AIR TIME DELAY VALVE

TIMING RANGE .2-20 SECONDS

MAC VAKVES INC.

MODEL 71A-2-2

Queie

AIRMATIC VALVE INC.

4) AIR CYLINDER

MILLER FLUID POWER CO.

MODEL 504, 1/4 NPT

(5) 4-WAY 5-PORT SPRING

RETURN VALVE

LUB.

9.

AIRMATIC VALVE INC. OR

VERSA PRODUCTS CO.

67) EXHAUST CONTROL

8) SHUT OFF VALVE

9) FILTER-REGULATOR-LUBRICATOR

COMBINATION WITH PRESSURE

GAUGE.

NORGREN

FILT.

PHOENIX

PHOENIX,

ARIZONA

UNIDYNAMICS

8.

A DIVISION OF UMC INDUSTRIES, INC.

TOOL NAME

PNEUMATIC CIRCUIT FOR

DEAD WEIGHT PRESS

SIZE CODE IDENT NO. DWG (TOOL) NO.

20-837

B 12079

Print supplied by Unidynar

PR 23-1. Pneumatic Circuit for Dead Weight Press.

Copyright Goodheart-Willcox Co., Inc.

B.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Electrical Transformers and Rotating Machines

Mechanical Engineering

ISBN:

9781305494817

Author:

Stephen L. Herman

Publisher:

Cengage Learning

Understanding Motor Controls

Mechanical Engineering

ISBN:

9781337798686

Author:

Stephen L. Herman

Publisher:

Delmar Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Electrical Transformers and Rotating Machines

Mechanical Engineering

ISBN:

9781305494817

Author:

Stephen L. Herman

Publisher:

Cengage Learning

Understanding Motor Controls

Mechanical Engineering

ISBN:

9781337798686

Author:

Stephen L. Herman

Publisher:

Delmar Cengage Learning