Unit 23 Instrumentation and Control Drawings 447 Name Date Class Industry Print Exercise 23-2 Refer to print PR 23-2. The sequence of operations for this print is given below. Answer the questions following the sequence of operations. of operations Sequence Description: This is a system to control a 90-ton hydraulic, explosive-compaction press. Thep a controlled rate, slowly compacting the explosive charge to avoid detonation due to a sudden shock. 1. The cycle is started by energizing solenoid A, which shifts control valve (3) and supplies pressure to press ram descends at the head end of the hydraulic cylinder (7). This operates the ram. 2. The cylinder (7) extends at a slow rate controlled by the fluid in the rod end of the cylinder, which is vented through the flow control valve (5). 3. When the cylinder is fully extended and the pressing pressure is reached, the pressure switch (6) de-energizes cylinder (7). Control valve (5) has an integral check valve that permits the free flow of fluid in the opposite direction, causing cylinder (7) to rapidly retract. AThe retraction of cylinder (7) actuates the limit switch (8), which de-energizes solenoid B. Control valve (3) returns to the neutral position. This completes the cycle. This circuit has safety features. On solenoid A and energizes solenoid B. This shifts control valve (3) to retract the power outage, both solenoid A and B are de-energized. This allows valve (3) to return to electrical the center position, thus stopping ram travel. Also, valve (4) provides low pressure relief on the ram upstroke and valve (2) provides high pressure relief on ram downstroke. Questions 1. What is the name of the circuit? 2. Give the drawing number. 3. What starts the sequence of operations? 4. When valve (3) shifts on energizing solenoid A, to which end of cylinder (7) is pressure supplied? 5. What causes the ram to extend at a slow, controlled rate? 6. What causes the ram to retract? Copyright Goodheart-Willcox Co., Inc. SNIPIISIN APPROVED DATE DESCRIPTION PLAS COMPONENT LIST 1) UNIDIRECTIONAL, FIXED- DISPLACEMENT HYDRAULIC PUMP AND MOTOR. 2) HIGH-PRESSURE RELIEF VALVE 3) 4-WAY, 3-POSITION, BLOCKED- CENTER, DOUBLE SOLENOID-ACTUATED, MAINTAINED- CONTACT, SPRING-CENTERED VALVE. 4) LOW-PRESSURE RELIEF VALVE. 5) FLOW CONTROL VALVE, ADJUSTABLE AND PRESSURE COMPENSATED WITH BYPASS. Sol. A Sol. B 6) PRESSURE SWITCH УХI 7 DOUBLE-ACTING HYDRAULIC CYLINDER. 8) LIMIT SWITCH TEM M HEAT TREAT FINISH MATERIAL STOCK SIZE ON NO. TALLEY INDUSTRIES MESA, ARIZONA MANUFACTURING ENGRG DEPT ENGRG CHANGE TOOL NAME 90 TON HYDRAULIC PRESS SCHEMATIC ENGRG PART NAME 90 TON COMPACTION PRESS UNLESS OTHERWISE NOTED R.K. WALKER 8/28 G.A.Schneider 8/28 NMRA TOLERANCES ON: ANGLES 1 CHECKED MACHINED DIA ON A COMMON CENTERLINE CONCENTRIC WITHIN 005 T.I.R NORMALITY AND PARALLELISM OF MACHINED SURFACES .002 PER INCH TO A MAX. OF .010 FOR A SINGLE SURFACE REMOVE BURRS AND SHARP EDGES .030 MAX ZONE APPROVED OF 1 SCCALE SHEET ENGRG PART NO. SIZE CODE IDENT, NO TOOL DRAWING N0 8568321 ZNE A 12116 449 Unit 23 Instrumentation and Control Drawings 00 669 TO CN DU CH Print supplied by Talley Industrie PR 23-2. 90 Ton Hydraulic Press Schematic Copyright Goodheart-Willcox Co., Inc.

Unit 23 Instrumentation and Control Drawings 447 Name Date Class Industry Print Exercise 23-2 Refer to print PR 23-2. The sequence of operations for this print is given below. Answer the questions following the sequence of operations. of operations Sequence Description: This is a system to control a 90-ton hydraulic, explosive-compaction press. Thep a controlled rate, slowly compacting the explosive charge to avoid detonation due to a sudden shock. 1. The cycle is started by energizing solenoid A, which shifts control valve (3) and supplies pressure to press ram descends at the head end of the hydraulic cylinder (7). This operates the ram. 2. The cylinder (7) extends at a slow rate controlled by the fluid in the rod end of the cylinder, which is vented through the flow control valve (5). 3. When the cylinder is fully extended and the pressing pressure is reached, the pressure switch (6) de-energizes cylinder (7). Control valve (5) has an integral check valve that permits the free flow of fluid in the opposite direction, causing cylinder (7) to rapidly retract. AThe retraction of cylinder (7) actuates the limit switch (8), which de-energizes solenoid B. Control valve (3) returns to the neutral position. This completes the cycle. This circuit has safety features. On solenoid A and energizes solenoid B. This shifts control valve (3) to retract the power outage, both solenoid A and B are de-energized. This allows valve (3) to return to electrical the center position, thus stopping ram travel. Also, valve (4) provides low pressure relief on the ram upstroke and valve (2) provides high pressure relief on ram downstroke. Questions 1. What is the name of the circuit? 2. Give the drawing number. 3. What starts the sequence of operations? 4. When valve (3) shifts on energizing solenoid A, to which end of cylinder (7) is pressure supplied? 5. What causes the ram to extend at a slow, controlled rate? 6. What causes the ram to retract? Copyright Goodheart-Willcox Co., Inc. SNIPIISIN APPROVED DATE DESCRIPTION PLAS COMPONENT LIST 1) UNIDIRECTIONAL, FIXED- DISPLACEMENT HYDRAULIC PUMP AND MOTOR. 2) HIGH-PRESSURE RELIEF VALVE 3) 4-WAY, 3-POSITION, BLOCKED- CENTER, DOUBLE SOLENOID-ACTUATED, MAINTAINED- CONTACT, SPRING-CENTERED VALVE. 4) LOW-PRESSURE RELIEF VALVE. 5) FLOW CONTROL VALVE, ADJUSTABLE AND PRESSURE COMPENSATED WITH BYPASS. Sol. A Sol. B 6) PRESSURE SWITCH УХI 7 DOUBLE-ACTING HYDRAULIC CYLINDER. 8) LIMIT SWITCH TEM M HEAT TREAT FINISH MATERIAL STOCK SIZE ON NO. TALLEY INDUSTRIES MESA, ARIZONA MANUFACTURING ENGRG DEPT ENGRG CHANGE TOOL NAME 90 TON HYDRAULIC PRESS SCHEMATIC ENGRG PART NAME 90 TON COMPACTION PRESS UNLESS OTHERWISE NOTED R.K. WALKER 8/28 G.A.Schneider 8/28 NMRA TOLERANCES ON: ANGLES 1 CHECKED MACHINED DIA ON A COMMON CENTERLINE CONCENTRIC WITHIN 005 T.I.R NORMALITY AND PARALLELISM OF MACHINED SURFACES .002 PER INCH TO A MAX. OF .010 FOR A SINGLE SURFACE REMOVE BURRS AND SHARP EDGES .030 MAX ZONE APPROVED OF 1 SCCALE SHEET ENGRG PART NO. SIZE CODE IDENT, NO TOOL DRAWING N0 8568321 ZNE A 12116 449 Unit 23 Instrumentation and Control Drawings 00 669 TO CN DU CH Print supplied by Talley Industrie PR 23-2. 90 Ton Hydraulic Press Schematic Copyright Goodheart-Willcox Co., Inc.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need parts 4, 5, and 6, answered pertaining to the print and instructions.

Transcribed Image Text:Unit 23

Instrumentation and Control Drawings

447

Name

Date

Class

Industry Print Exercise 23-2

Refer to print PR 23-2. The sequence of operations for this print is given below. Answer the questions following the

sequence of operations.

of operations

Sequence

Description: This is a system to control a 90-ton hydraulic, explosive-compaction press. Thep

a controlled rate, slowly compacting the explosive charge to avoid detonation due to a sudden shock.

1. The cycle is started by energizing solenoid A, which shifts control valve (3) and supplies pressure to

press

ram descends at

the head end of the hydraulic cylinder (7). This

operates

the

ram.

2. The cylinder (7) extends at a slow rate controlled by the fluid in the rod end of the cylinder, which is

vented through the flow control valve (5).

3. When the cylinder is fully extended and the pressing pressure is reached, the pressure switch (6)

de-energizes

cylinder (7). Control valve (5) has an integral check valve that permits the free flow of fluid in the

opposite direction, causing cylinder (7) to rapidly retract.

AThe retraction of cylinder (7) actuates the limit switch (8), which de-energizes solenoid B. Control

valve (3) returns to the neutral position. This completes the cycle. This circuit has safety features. On

solenoid A and energizes solenoid B. This shifts control valve (3) to retract the

power outage, both solenoid A and B are de-energized. This allows valve (3) to return to

electrical

the center position, thus stopping ram travel. Also, valve (4) provides low pressure relief on the ram

upstroke and valve (2) provides high pressure relief on ram downstroke.

Questions

1. What is the name of the circuit?

2. Give the drawing number.

3. What starts the sequence of operations?

4. When valve (3) shifts on energizing solenoid A, to which end of cylinder (7) is pressure supplied?

5. What causes the ram to extend at a slow, controlled rate?

6. What causes the ram to retract?

Copyright Goodheart-Willcox Co., Inc.

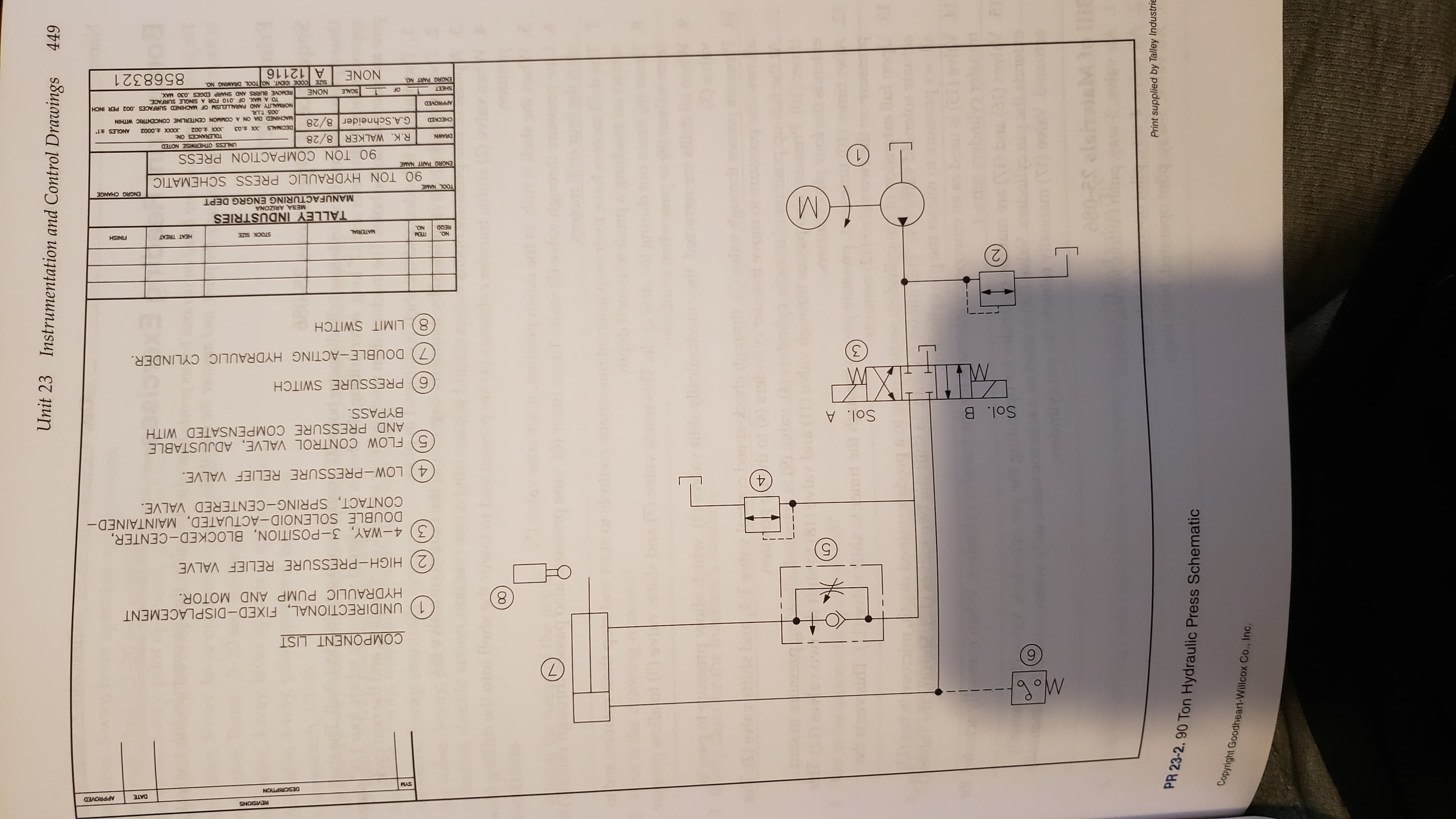

Transcribed Image Text:SNIPIISIN

APPROVED

DATE

DESCRIPTION

PLAS

COMPONENT LIST

1) UNIDIRECTIONAL, FIXED- DISPLACEMENT

HYDRAULIC PUMP AND MOTOR.

2) HIGH-PRESSURE RELIEF VALVE

3) 4-WAY, 3-POSITION, BLOCKED- CENTER,

DOUBLE SOLENOID-ACTUATED, MAINTAINED-

CONTACT, SPRING-CENTERED VALVE.

4) LOW-PRESSURE RELIEF VALVE.

5) FLOW CONTROL VALVE, ADJUSTABLE

AND PRESSURE COMPENSATED WITH

BYPASS.

Sol. A

Sol. B

6) PRESSURE SWITCH

УХI

7 DOUBLE-ACTING HYDRAULIC CYLINDER.

8) LIMIT SWITCH

TEM

M

HEAT TREAT

FINISH

MATERIAL

STOCK SIZE

ON

NO.

TALLEY INDUSTRIES

MESA, ARIZONA

MANUFACTURING ENGRG DEPT

ENGRG CHANGE

TOOL NAME

90 TON HYDRAULIC PRESS SCHEMATIC

ENGRG PART NAME

90 TON COMPACTION PRESS

UNLESS OTHERWISE NOTED

R.K. WALKER 8/28

G.A.Schneider 8/28

NMRA

TOLERANCES ON:

ANGLES 1

CHECKED

MACHINED DIA ON A COMMON CENTERLINE CONCENTRIC WITHIN

005 T.I.R

NORMALITY AND PARALLELISM OF MACHINED SURFACES .002 PER INCH

TO A MAX. OF .010 FOR A SINGLE SURFACE

REMOVE BURRS AND SHARP EDGES .030 MAX

ZONE

APPROVED

OF 1 SCCALE

SHEET

ENGRG PART NO.

SIZE CODE IDENT, NO TOOL DRAWING N0

8568321

ZNE

A 12116

449

Unit 23 Instrumentation and Control Drawings

00

669

TO

CN

DU CH

Print supplied by Talley Industrie

PR 23-2. 90 Ton Hydraulic Press Schematic

Copyright Goodheart-Willcox Co., Inc.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY