Concept explainers

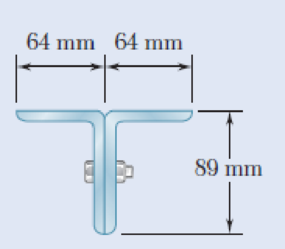

Two 89 × 64-mm angles are bolted together as shown for use as a column of 2.4-m effective length to carry a centric load of 325 kN. Knowing that the angles available have thicknesses of 6.4 mm, 9.5 mm, and 12.7 mm, use allowable stress design to determine the lightest angles that can be used. Use σY = 250 MPa and E = 200 GPa.

Fig. P10.84

Find the lightest angles that can be used.

Answer to Problem 84P

The lightest angle that can be used for the design is

Explanation of Solution

Given information:

The effective length of the column is

The allowable yield strength of the steel is

The modulus of elasticity of the steel is

The centric load acting in the column is

Calculation:

Consider the thickness of the angle section as 9.5 mm.

Refer to Appendix C “Properties of Rolled-Steel Shapes” in the textbook.

For

The cross sectional area of the angle (A) is

The moment of inertia in x-axis is

The moment of inertia in y-axis is

The centroid distance from the flange in x-axis is

The area of the two angle section is

The moment of inertia in x-axis is

Find the moment of inertia in y-axis using the relation.

Substitute

The minimum moment of inertia is

Find the minimum radius of gyration (r) using the relation.

Substitute

Find the slenderness ratio

Here, the modulus of elasticity of the material is E and the allowable yield strength is

Substitute 200 GPa for E and 250 MPa for

Find the ratio of effective length

Find the effective stress

Substitute 200 GPa for E and 97.22 for

Find the critical stress

Substitute 250 MPa for

Calculate the allowable stress

Substitute 151.472 MPa for

Calculate the allowable load

Substitute 90.702 MPa for

The centric load is greater than the allowable load. Hence, the design is unsafe.

Consider the thickness of the angle section as 12.7 mm.

Refer to Appendix C “Properties of Rolled-Steel Shapes” in the textbook.

For

The cross sectional area of the angle (A) is

The moment of inertia in x-axis is

The moment of inertia in y-axis is

The centroid distance from the flange in x-axis is

The area of the two angle section is

The moment of inertia in x-axis is

Find the moment of inertia in y-axis using the relation.

Substitute

The minimum moment of inertia is

Find the minimum radius of gyration (r) using the relation.

Substitute

Find the slenderness ratio

Here, the modulus of elasticity of the material is E and the allowable yield strength is

Substitute 200 GPa for E and 250 MPa for

Find the ratio of effective length

Find the effective stress

Substitute 200 GPa for E and 95.12 for

Find the critical stress

Substitute 250 MPa for

Calculate the allowable stress

Substitute 154.753 MPa for

Calculate the allowable load

Substitute 92.667 MPa for

The centric load is less than the allowable load. Hence, the design is unsafe.

Therefore, the lightest angle that can be used for the design is

Want to see more full solutions like this?

Chapter 10 Solutions

EBK MECHANICS OF MATERIALS

- Column ABC has a uniform rectangular cross section with b=12 mm and d=22 mm. The column is braced in the xz plane at its midpoint C and carries a centric load P of magnitude 3.8 kN. Knowing that a factor of safety of 3.2 is required, determine the largest allowable length L. Use E=200 GPaarrow_forwardA load P is supported as shown by a steel pin that has been inserted in a short wooden member hanging from the ceiling. The ultimate strength of the wood used is 60 MPa in tension and 7.5 MPa in shear,while the ultimate strength of the steel is 145 MPa in shear. Knowing that b = 40 mm, c = 55 mm, and d = 12 mm, determine the load P if an overall factor of safety of 3.2 is desired.arrow_forwardEach of the two vertical links CF connecting the two horizontal members AD and EG has a 10x40-mm uniform rectangular cross section and is made of a steel with an ultimate strength in tension of 400 MPa,while each of the pins at C and F has a 20-mm diameter and is made of a steel with an ultimate strength in shear of 150 MPa. Determine the overall factor of safety for the links CF and the pins connecting them to the horizontal members.arrow_forward

- The length of the 332332 -in.-diameter steel wire CD has been adjusted so that with no load applied, a gap of 116116 in. exists between the end B of the rigid beam ACB and contact point E. Knowing that E = 29 × 106 psi, determine where a 57-lb (w) block should be placed on the beam in order to cause contact between B and E. For contact, x < in.arrow_forwardA glue-laminated column of 3-m effective length is to be made from boards of 24 x 100-mm cross section. Knowing that for the grade of wood used, E= 11 GPa and the adjusted allowable stress for com-pression parallel to the grain is σC= 9 MPa, determine the number of boards that must be used to support the centric load shown when (a) P= 34 kN, (b) P= 17 kNarrow_forwardColumn ABC has a uniform rectangular cross section and is braced in the xz plane at its midpoint C. (a) Determine the ratio b/d for which the factor of safety is the same with respect to buckling in the xz and yz planes. (b) Using the ratio found in part a, design the cross section of the column so that the factor of safety will be 3.0 when P= 4.4 kN, L=1 m, and E=200 GPaarrow_forward

- Each of the five struts shown consists of a solid steel rod. (a) Know-ing that strut (1) is of a 0.8-in. diameter, determine the factor of safety with respect to buckling for the loading shown. (b) Determine the diameter of each of the other struts for which the factor of safety is the same as the factor of safety obtained in part a. Use E=29 *106 psiarrow_forwardA column of 22-ft effective length is to be made by welding two 9 *0.5-in. plates to a W8 * 35 rolled steel shape as shown. Determine the allowable centric load if a factor of safety 2.3 is required. Use E=29 *106 psiarrow_forwardIn the structure shown, an 8-mm-diameter pin is used at A, and 12-mm-diameter pins are used at B and D. Knowing that the ultimate shearing stress is 100 MPa at all connections and that the ultimate normal stress is 250 MPa in each of the two links joining B and D, determine the allowable load P if an overall factor of safety of 2.6 is desired.arrow_forward

- A column of 3-m effective length is to be made by welding together two C130 *13 rolled-steel channels. Using E= 200 GPa, determine for each arrangement shown the allowable centric load if a factor of safety of 2.4 is required.arrow_forwardIn the steel structure shown, a 6-mm-diameter pin is used at C and 12-mm-diameter pins are used at B and D. The ultimate shearing stress is 150 MPa at all connections, and the ultimate normal stress is 350 MPa in link BD. Knowing that a factor of safety of 3.0 is desired, determine the largest load P that can be applied at A. Note that link BD is not reinforced around the pin holes. The largest load P that can be applied at A is kN.arrow_forwardEach of the four vertical Ilinks has an 8 x 36-mm uniform rectangular cross section and each of the four pins has a 16-mm diameter. Take P= 19 kN. 0.4 m C 0.25 m 0.2 m B. P Determine the average bearing stress at Bin member ABC, knowing that this member has a 10 x 50-mm uniform rectangular cross section. MPa. The average bearing stress at Bin member ABC is.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY