Concept explainers

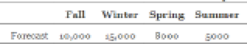

A small textile company makes several types of sweaters. Demand is very seasonal, as shown by the following quarterly demand estimates. Demand is estimated in terms of standard hours of production required.

All hour of regular time costs the company $12. Employees are paid $18 per hour 011 overtime, and labor can be subcontracted from the outside at $14 per hour. A maximum of 1000 overtime hours is available in any month. A change in the regular level of production (increase or decrease) incurs a onetime cost of $5 per hour for adding or subtracting an hour of labor. It costs 2 percent per month to carry an hour of finished work in inventory. Materials and overhead costs in inventory are equal to the direct labor costs. At the beginning of the fall quarter, there are 5000 standard hours in inventory and die workforce level is equivalent to 10,000 standard hours.

- a. Suppose management sets the level of regular workers for the year equal to the average demand and subcontracts out the rest. What is the cost of this strategy'?

- b. What is the cost of a chase strategy?

Trending nowThis is a popular solution!

Chapter 11 Solutions

OPERATIONS MANAGEMENT IN SUPPLY CHAIN

- Southeast Soda Pop, Inc., has a new fruit drink for which it has high hopes. John Mittenthal, the production planner, has assembled the following cost data and demand forecast: demand forecast. Quarter Forecast 1 1,900 2 1,200 3 1,600 4 800 Costs/Other Data Previous quarter's output=1,200 cases Beginning inventory=0 cases Stockout cost of backorders=$160 per case Inventory holding cost=$40 per case at end of quarter Hiring employees=$35 per case Terminating employees=$80 per case Subcontracting cost=$65 per case Unit cost on regular time=$30 per case Overtime cost=$20 extra per case Capacity on regular time=1,900 cases per quarter John's job is to develop an aggregate plan. The three initial options he wants to evaluate are: • Plan A: a strategy that hires and fires personnel as necessary to meet the forecast. • Plan B: a level strategy. • Plan C: a level strategy that…arrow_forwardA Pizza Company has a demand forecast for the next 12 months that is shown in Table 1 The current workforce of 100 staff can produce 1500 cases of pizzas per month. (a) Prepare a production plan that keeps the output level. How much warehouse space would the company need for this plan? (b) Prepare a demand chase plan. What implications would this have for staffing levels, assuming that the maximum amount of overtime would result in production levels of only 10 per cent greater than normal working hours? Table 1 demand forecast Month Demand (cases per month) January 600 February 800 March 1000 April 1500 May 2000 June 1700 July…arrow_forwardDevelop a production plan and calculate the annual cost for a firm whose demand forecast is fall, 10,000; winter, 8,000; spring, 7,000; summer, 12,000. Inventory at the beginning of fall is 500 units. At the beginning of fall, you currently have 30 workers, but you plan to hire temporary workers at the beginning of summer and lay them off at the end of summer. In addition,you have negotiated with the union an option to use the regular workforce on overtime during winter or spring if overtime is necessary to prevent stock-outs at the end of those quarters. Overtime is not available during the fall. Relevant costs are hiring, $100 for each temp; layoff, $200 for each worker laid off; inventory holding, $5 per unit-quarter; backorder, $10 per unit; straight time, $5 per hour; over time, $8 per hour. Assume that productivity is 0.5 units per worker hour, with eight hours per day and 60 days per season. (Answer in Appendix D)arrow_forward

- Develop a production plan and calculate the annual cost for a firm whose demand forecast is fall, 11,000; winter, 8,000; spring, 6,000; summer, 13,000. Inventory at the beginning of fall is 500 units. At the beginning of fall you currently have 30 workers, but you plan to hire temporary workers at the beginning of summer and lay them off at the end of summer. In addition, you have negotiated with the union an option to use the regular workforce on overtime during winter or spring if overtime is necessary to prevent stockouts at the end of those quarters. Overtime is not available during the fall. Relevant costs are hiring, $100 for each temp; layoff $200 for each worker laid off; inventory holding, $5 per unit-quarter; backorder, $10 per unit; straight time, $5 per hour; overtime, $8 per hour. Assume that the productivity is 0.5 unit per worker hour, with eight hours per day and 60 days per season. a. What is the total cost for this plan?arrow_forwardThe demand information is given below. Month Jan Feb Mar Apr May Jun Demand 1,900 2,800 4,700 5,600 5,600 1,750 A worker can produce 25 units per month. Assume that the beginning inventory in January is 450 units, and the firm desires to have 300 units of inventory at the end of June. Use a chase production strategy to compute the monthly production, ending inventory/(backlog) and workforce levels. Do not round intermediate calculations. Round your answers to the nearest whole number. Use a minus sign to enter a negative value, if any. If your answer is zero, enter "0". Month Jan Feb Mar Apr May Jun Demand 1,900 2,800 4,700 5,600 5,600 1,750 Production Ending inventory 450 Workforce Use a level production strategy to compute the monthly production, ending inventory/(backlog) and workforce levels. Do not round intermediate calculations. Round your answers to the nearest whole number. Use a minus sign to enter a negative value, if any. If your answer is zero, enter "0". Month Jan Feb Mar…arrow_forwardPlan production for the next year. The demand forecast is: spring, 20,000; summer, 10,000; fall, 15,000; winter, 18,000. At the beginning of spring, you have 70 workers and 1,000 units in inventory. The union contract specifies that you may lay off workers only once a year, at the beginning of summer. Also, you may hire new workers only at the end of summer to begin regular work in the fall. The number of workers laid off at the beginning of summer and the number hired at the start of fall should result in planned production levels for summer and fall that equal the demand forecasts for summer and fall, respectively. If demand exceeds supply, use overtime in spring only, which means that backorders could occur in winter. You are given these costs: hiring, $100 per new worker; layoff, $200 per worker laid off; holding, $20 per unit-quarter; backorder cost, $8 per unit; straight-timelabor, $10 per hour; over time, $15 per hour. Productivity is 0.5 units per worker hour, eight hours per…arrow_forward

- evelop a production plan and calculate the annual cost for a firm whose demand forecast is fall, 9,700; winter, 8,000; spring, 7,000; summer, 11,700. Inventory at the beginning of fall is 485 units. At the beginning of fall you currently have 35 workers, but you plan to hire temporary workers at the beginning of summer and lay them off at the end of summer. In addition, you have negotiated with the union an option to use the regular workforce on overtime during winter or spring only if overtime is necessary to prevent stockouts at the end of those quarters. Overtime is not available during the fall. Relevant costs are hiring, $80 for each temp; layoff, $160 for each worker laid off; inventory holding, $5 per unit-quarter; backorder, $10 per unit; straight time, $5 per hour; overtime, $8 per hour. Assume that the productivity is 0.5 unit per worker hour, with eight hours per day and 60 days per season. In each quarter, produce to the full output of your regular workforce, even if that…arrow_forwardPlan production for a four-month period: February through May. For February and March, you should produce to exact demand forecast. For April and May, you should use overtime and inventory with a stable workforce; stable means that the number of workers needed for March will be held constant through May. However, government constraints put a maximum of 5,000 hours of overtime labor per month in April and May (zero overtime in February and March). If demand exceeds supply, then backorders occur. There are 100 workers on January 31. You are given the following demand forecast: February, 90,000; March 65,000; April 110,000; May, 55,000. Productivity is four units per worker hour, eight hours per day, 20 days per month. Assume zero inventory on February 1. Costs are hiring, $50 per new worker; layoff, $70 per worker laid off; inventory holding, $10 per unit-month; straight-time labor, $10 per hour; overtime, $15 per hour; backorder, $20 per unit a. Find the total cost of this plan?arrow_forwardDevelop a production plan and calculate the annual cost for a firm whose demand forecast is: fall, 10,100; winter, 8,100; spring, 7,100; summer, 12,100. Inventory at the beginning of fall is 505 units. At the beginning of fall you currently have 30 workers, but you plan to hire temporary workers at the beginning of summer and lay them off at the end of summer. In addition, you have negotiated with the union an option to use the regular workforce on overtime during winter or spring if overtime is necessary to prevent stock-outs at the end of those quarters. Overtime is not available during the fall. Relevant costs are hiring, $100 for each temp; layoff, $200 for each worker laid off; inventory holding, $5 per unit-quarter; backorder, $10 per unit; regular time, $5 per hour; overtime, $8 per hour. Assume that the productivity is 0.5 unit per worker hour, with eight hours per day and 60 days per season. In each quarter, produce to the full output of your regular workforce, even if that…arrow_forward

- You have been asked to estimate the cost of 100 prefabricated structures to be sold to a local school district. Each structure provides 1,000 square feet offloor space, with 8-feet ceilings. In 1999, you produced 70 similar structures consistingof the same materials and having the same ceiling height, but each provided only 800square feet of floor space. The material cost for each structure was $25,000 in 1999, andthe cost capacity factor is 0.65. The cost index values for 1999 and 2006 are 200 and 289,respectively. The estimated manufacturing cost for the first 1,000-square-foot structureis $12,000. Assume a learning curve of 88% and use the cost of the 50th structure asyour standard time for estimating manufacturing cost. Estimate the total material costand the total manufacturing cost for the 100 prefabricated structures.arrow_forwardMavis and John have joined forces to start M&J Food Products, a processor of packaged shredded lettuce for institutional use. John has years of food processing experience, and Mavis has extensive commercial food preparation experience. The process will consist of opening crates of lettuce and then sorting, washing, slicing, preserving, and finally packaging the prepared lettuce. Together, with help from vendors, they think they can adequately estimate demand, fixed costs, revenues, and variable cost per 5-pound bag of lettuce. They think a largely manual process will have monthly fixed cost of $50,000and a variable cost of $2.50 per bag. They expect to sell 75,000 bags of lettuce per month. They expect to sell the shredded lettuce for $3.25 per 5-pound bag. John and Mavis has been contacted by a vendor to consider a more mechanized process. This new process will have monthly fixed cost of $125,000 per month with a variable cost of $1.75 per bag. Based on the above scenario: Should…arrow_forwardThe president of HiU Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 monthsas follows: Her operat ions manager is considering a new pla n, whichbegins in January with 200 uni ts on hand . Stockout cost of lostsales is SlOO per unit. Inventory holding cost is $20 per unit permonth. Ignore any idle-time costs. The plan is called plan A.Plan A: Vary the workforce level to execute a strategy that producesthe quantity demanded in the prior month. The Decemberdemand and rate of production are both I ,600 units per month. Thecost of hiring additional workers is $5,000 per I 00 uruts. The cost oflaying oiTworkers is $7,500 per 100 units. Evaluate this plan.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing