The greatest amount of exergy destroyed among the processes of system.

Answer to Problem 117RP

The greatest amount of exergy destroyed among the processes of system is

Explanation of Solution

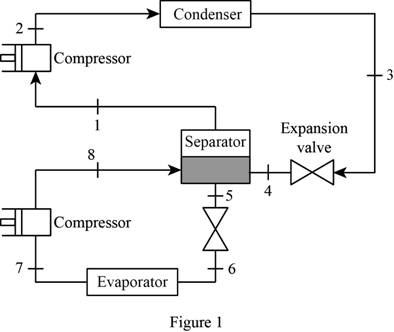

Sketch the schematic layout of the two-stage compression refrigeration system as in Figure (1).

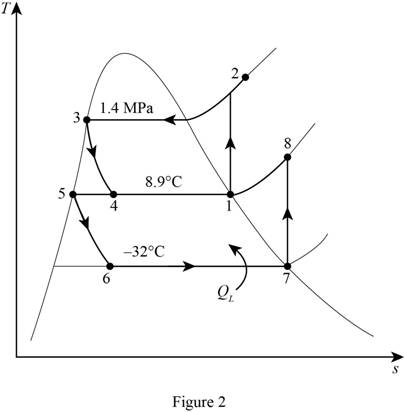

Sketch the

Write the relation between the specific enthalpies at the inlet and exit of throttling.

Here, specific enthalpy of the refrigerant at the inlet of throttling is

Write the energy balance equation for the separator.

Here, mass flow rate of the refrigerant at the end of high pressure compressor is

Write the expression to calculate the quality of the refrigerant

Here, specific enthalpy of the saturated liquid is

Write the expression to calculate the specific entropy for saturated refrigerant

Here, specific entropy of the saturated liquid is

Write the expression to calculate the rate of cooling produced

Here, specific enthalpy at the inlet of low pressure compressor is

Write the expression to calculate the rate of heat rejected from the system

Here, specific enthalpy at the exit of high pressure compressor is

Write the general expression to calculate the exergy destruction

Here, mass flow rate is

Conclusion:

From the Table A-11 of “Saturated refrigerant R-134a: Temperature”, obtain the properties of refrigerant at high pressure compressor inlet temperature

From the Table A-13 of “Superheated refrigerant R-134a”, obtain the specific enthalpy of high pressure compression exit at pressure

From the Table A-12 of “Saturated refrigerant R-134a: Pressure”, obtain the properties of refrigerant at high pressure cycle throttle inlet pressure of

Substitute

From the Table A-12 of “Saturated refrigerant R-134a: Pressure”, obtain the properties of refrigerant at high pressure cycle throttle exit temperature of

Substitute

Substitute

From the Table A-12 of “Saturated refrigerant R-134a: Pressure”, obtain the properties of refrigerant at low pressure cycle throttle inlet temperature of

Here, pressure of refrigerant at the separator is

Substitute

From the Table A-11 of “Saturated refrigerant R-134a: Temperature”, obtain the properties of refrigerant at low pressure expansion valve exit temperature

Substitute

Substitute 0.2437 for

From the Table A-11 of “Saturated refrigerant R-134a: Temperature”, obtain the properties of refrigerant at low pressure compressor inlet temperature

From the Table A-13 of “Superheated refrigerant R-134a”, obtain the specific enthalpy of low pressure compression exit at pressure

Substitute

Substitute

Substitute

Rewrite the Equation (VII) for the process 2 to 3.

Here, the temperature of the high temperature reservoir is

Substitute

Rewrite the Equation (VII) for the process 3 to 4.

Substitute

Rewrite the Equation (VII) for the process 5 to 6.

Substitute

Rewrite the Equation (VII) for the process 6 to 7.

Substitute

Rewrite the Equation (VII) for the separator process.

Substitute

The exergy destruction for the isentropic processes is zero. Hence,

Thus, the greatest amount of exergy destroyed among the processes of system is

Want to see more full solutions like this?

Chapter 11 Solutions

Thermodynamics: An Engineering Approach

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY