Concept explainers

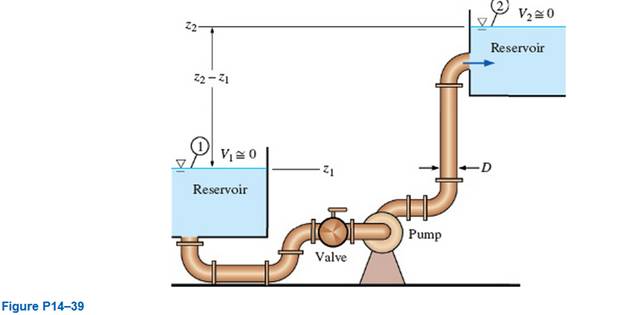

A water pump is used to pump water from one large reservoir to another large reservoir that is at a higher elevation. The free surfaces of both reservoirs are exposed to atmospheric pressure, as sketched in Fig. P 14-39. The dimensions and minor loss coefficients are provided in the figure. The pump' s performance is approximated by the expression

The volume capacity delivered by the pump.

Answer to Problem 43P

The volume capacity delivered by the pump is

Explanation of Solution

Given information:

The diameter of pipe is

Write the expression for head required.

Here, pressure at exit is

Write the expression for coefficient of total minor head loss.

Here, coefficient of entrance loss is

Write the expression for head loss.

Here, length of pipe is

Write the expression for

Here, shutoff head is

Write the expression for Reynolds number.

Here, density of water is

Write the expression for Colebrook equation.

Here, coefficient of friction is

Write the expression for volume flow rate.

Calculation:

Substitute

Substitute

Substitute

Substitute

Refer Table-A-3 "Properties of saturated water" at

Substitute

Substitute

Substitute

Here, apply hit and trial method to calculate the velocity of flow.

Trial-(1)

Substitute

Since the value on both sides are not equal, so assumption of

Trial-(2)

Substitute

Here, the values on both sides are equal, so assumption is correct and velocity of flow is

Substitute

Conclusion:

The volume capacity delivered by the pump is

Want to see more full solutions like this?

Chapter 14 Solutions

Connect 1 Semester Access Card For Fluid Mechanics Fundamentals And Applications

- In a hydroelectric power plant as shown in the figure, 100 m3/s of water flows froman elevation of 130 meters to the turbine, where electric power is generated. The overallefficiency of the turbine-generator is 80%. Disregarding frictional loss in piping, estimate the electric power output of this plant.arrow_forwardWater at 15°C is to be discharged from a reservoir at a rate of 18 L/s using two horizontal cast iron pipes connected in series and a pump between them. The first pipe is 20 m long and has a 6-cm diameter, while the second pipe is 35 m long and has a 3-cm diameter. The water level in the reservoir is 30 m above the centerline of the pipe. The pipe entrance is sharp-edged, and losses associated with the connection of the pump are negligible. Neglecting the effect of the kinetic energy correction factor, determine the required pumping head and the minimum pumping power to maintain the indicated flow rate.arrow_forwardWater at 15°C is to be discharged from a reservoir at a rate of 18 L/s using two horizontal cast iron pipes connected in series and a pump between them. The first pipe is 20 m long and has a 6-cm diameter, while the second pipe is 35 m long and has a 3-cm diameter. The water level in the reservoir is 30 m above the centerline of the pipe. The pipe entrance is sharp-edged, and losses associated with the connection of the pump are negligible.Using appropriate software, investigate the effect of the second pipe diameter on the required pumping head to maintain the indicated flow rate. Let the diameter vary from 1 to 10 cm in increments of 1 cm. Tabulate and plot the resultsarrow_forward

- Water at 15°C is to be discharged from a reservoir at a rate of 18 L/s using two horizontal cast iron pipes connected in series and a pump between them. The first pipe is 5 m long and has a 6-cm diameter, while the second pipe is 5 m long and has a 4-cm diameter. The water level in the reservoir is 30 m above the centerline of the pipe. The pipe entrance is sharp-edged, and losses associated with the connection of the pump are negligible. Neglecting the effect of the kinetic energy correction factor, determine the required pumping head and the minimum pumping power to maintain the indicated flow rate. (The density and dynamic viscosity of water at 15°C are ρ = 999.1 kg/m3 and μ = 1.138x10-3 kg/m.s. The loss coefficient is KL = 0.5 for a sharp-edged entrance. The roughness of cast iron pipes is ε= 0.00026 m.)arrow_forwardPump Horsepower in Brine System. A pump pumps 0.200 ft3/s of brine solution having a density of 1.15 g/cm3 from an open feed tank having a large cross-sectional area. The suction line has an inside diameter of 3.548 in. and the discharge line from the pump a diameter of 2.067 in. The discharge flow goes to an open overhead tank, and the open end of this line is 75 ft above the liquid level in the feed tank. If the friction losses in the piping system are 18.0 ft lbf/lb m, what pressure must the pump develop and what is the horsepower of the pump if the efficiency is 70%? The flow is turbulent.arrow_forwardAs can be seen in the figure, the level difference between the two tanks open to the atmosphere is H = 25 m. The fluid in the lower tank is pumped into the upper tank with the help of a centrifugal pump. The continuous loss coefficient of the pipe made of forged steel, f = 0.025, the elbow loss coefficient K = 1. Other losses in the system are neglected. The pipe diameter is D = 16 cm and the flow through the pipe is V = 0.15 m3 / s. According to this;a) Find the pump power.b) Find the pressure at the pump suction pipe inlet.c) Find the pressure at the pump discharge pipe outlet.d) Draw the Energy Slope line and Hydraulic slope lines .arrow_forward

- Consider a pipe that branches out into two parallel pipes and then rejoins at a junction downstream. The two parallel pipes have the same lengths and friction factors. The diameters of the pipes are 2 cm and 4 cm. If the head loss in one pipe is 0.5 m, the head loss in the other pipe is (a) 0.5 m (b) 1 m (c) 0.25 m (d) 2 m (e) 0.125 marrow_forwardWater enters a hydraulic turbine through a 30 cm diameter pipe at a rate of 0.6 m3/s and exits through a 25 cm diameter pipe as shown in the Figure. The pressure drop in the turbine is measured by a mercury manometer to be 1.2 m. For a combined turbine– generator efficiency of 83 percent, determine the net electric power output. Take the kinetic energy correction factor to be 1.05. (Density of water and mercury can be taken as per the standards)arrow_forwardWater enters a hydraulic turbine through a 30 cm diameter tube at a rate of 0.6 m3/s and leaves through a 25 cm diameter tube. cm in diameter With a mercury manometer, the pressure drop across the turbine is measured to be 1.2 m For a combined efficiency (turbine-generator) of 83%, determine the net electrical power output. discard the effect of the kinetic energy correction factors.arrow_forward

- Determine (a) the head loss, (b) the pressure drop, and (c) the pumping power for water flowing steadily at 40°F (ρ=62.42 lbm/ft3 and μ=1.038x10-3 lbm/ft-s) through a 0.15-in diameter, 45-ft-long horizontal pipe at an average velocity of 2.5 ft/s. Round off your answers to three (3) decimal places.arrow_forwardWater at 25oC is pumped at a constant rate of 10 m3/h from a large reservoir resting on the floorto the open top of an experimental absorption tower. The point of discharge 5 m above the floor,and friction losses in the 1-½-in. Schedule 40 steel pipe from the reservoir to the tower amount to2.55 J/kg. At what height in the reservoir must the water level be kept if the pump can deliver only0.1 kW?arrow_forwardWater from a reservoir is pumped over a hill through a pipe 30 cm in diameter, and a pressure of 250 KPa is maintained at the summit where the pipe is 100 m above the reservoir. The quantity pumped is 0.20 m3/s and by reason of friction there is a head loss of 15 J/N between reservoir and summit. If the pump is 80% efficient and its motor is 90% efficient, determine the input power of the pump.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY