Concept explainers

The KC Machine Works, which does job shop machining, has received an order to make 40 duplicate pieces, made of AISI 4140 steel, which will require 1 hr/piece of actual cutting time if a high-speedsfeel (M1) milling cutter is used. Abigail Langley, a new machinist, says the cutting time could be reduced significantly if the company would purchase a suitable tungsten carbide milling cutter. Paul Zachary, the foreman for the milling area, says he does not believe that Abigail’s estimate is realistic, and he is not going to spend $450 (the current price from the vendor) of the company’s money on a carbide cutter that probably would not be used again. The machine hour rate, including labor for the shop is S40/h.

Abigail and Paul have come to you, the manufacturing engineer (MfE) of the plant, for a decision on whether to buy the cutter, which is readily available from a local supplier.

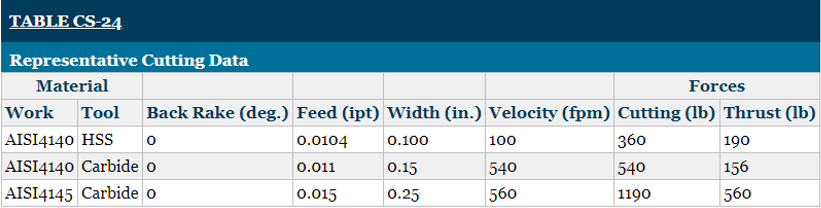

What factors should you consider in this situation? How much faster could the carbide cutter cut compared to the HSS cutter? See Table CS-24. Based on your best guess as to the savings in actual cutting time per piece, who do you think is correct: Abigail or Paul?

Want to see the full answer?

Check out a sample textbook solution

Chapter 24 Solutions

Degarmo's Materials And Processes In Manufacturing

Additional Engineering Textbook Solutions

Statics and Mechanics of Materials (5th Edition)

Applied Statics and Strength of Materials (6th Edition)

Mechanics of Materials (10th Edition)

Manufacturing Engineering & Technology

Applied Fluid Mechanics (7th Edition)

Fundamentals Of Thermodynamics

- In a machine test, a cutting speed of 100 m/min indicated the tool life as 16 min and a cutting speed of 200 m/min indicated the tool life as 4 min. Calculate the values of n and C.arrow_forwardIn an orthogonal cutting operation an 8 mm deep groove is to be turned on a 50 mm diameter steel bar. Spindle speed is 300 rpm and a feed rate of 0.25 mm/rev is given to the tool. Produced chips have a width of 2 mm. Calculate the material removal rate at the beginning and at the end of the cut. Can u help me please?arrow_forwardCalculate the machining time intervals for face milling a cutter 10 inches long, 2 inches wide, with a depth of cut of 0.1 inch for the following workpiece materials: (a) low-carbon steel ; (b) titanium alloys; (c) aluminum alloys, and (d) thermoplastics.arrow_forward

- A slab milling operation is performed on the top surface of a tool-steel workpiece 450 mm long by 7.5 cm wide. The helical milling cutter, which has an 80 mm diameter and seven teeth, is set up to overhang the width of the part on both sides. Cutting speed is 4000 mm/min, feed is 0.015 cm/tooth, and depth of cut = 0.60 cm. Determine (a) the actual machining time to make one pass across the surface and (b) the maximum metal removal rate during the cut. (c) If an additional approach distance of 0.05 m is added at the beginning of the pass, and an overtravel distance at the end of the pass equal to the cutter radius plus 0.0115 cm, what is the duration of the feed motionarrow_forwardIn a machining operation, doubling the cutting speed reduces the tool life to 1/8th of the original value. What is the exponent n in Taylor's tool life equation VTn = C,arrow_forwardPlease solve question 2,3 and 13. Determine the % change in the machine time for an USM operation cutting WC plate when the tool material is changed from copper to stainless steel. Take ratio of flow stress of WC to flow stress of copper is 4.6 and the ratio of flow stress of WC to the flow stress of SST is 1.2.arrow_forward

- (a) Explain the difference between roughing and finishing operations in machining.(b) What are the parameters of a machining operation that are included within the scope of cuttingconditions?(c) What is the difference between threading and tapping?(d) A cylindrical workpiece is to be turned in a lathe. Determine the material removal rate if thecutting speed = 2.30 m/s, feed = 0.32 mm/rev, and depth of cut = 1.8 mm.(e) In a turning operation using high-speed steel tooling, the cutting speed = 110 m/min. The Taylortool life equation has parameters n = 0.140 and C = 150 (m/min) when the operation is conducteddry. When a coolant is used in the operation, the value of C is increased by 15%. Determine thepercent increase in tool life that will result if the cutting speed is maintained at 110 m/min.arrow_forwardQ#2 “Milling is an intermitted cutting operation”. Explain it.arrow_forwardCalculate the time required for completing a 5mm deep finishing cut on a 150mm wide, 600mmlong face of a 25mm thick steel block using a face milling cutter of 150mm diameter with 6teeth. The cutting condition are Vc =1.5m/sec and fz = 0.1mm.arrow_forward

- For turning operation, using the table below, find an approximate value for the required speed of rotation of the chuck, in rpm, if the cutting speed for the material 5417 mm/s and the radius of the wp is 0.01 m. Show details of your answer. n | we| oarrow_forwardIf a fairing operation is executed at a rotational speed of 40.0 rev / min, the feed is 0.015 in / rev and the depth of cut is 0.180 in, it determines: a) cutting time to complete the fairing operation; and b) the cutting speed; and c) The speed of metal removal at the beginning and end of the cut d) The power dissipated.arrow_forwardQ6) Explain the various milling cutters used in industry with their typical applications.arrow_forward

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning