Concept explainers

(a)

The tangent elastic modulus.

(a)

Answer to Problem 6.19P

The tangent elastic modulus at zero strain is

Explanation of Solution

Formula Used:

Write the expression for the tangent elastic modulus.

Here,

Calculation:

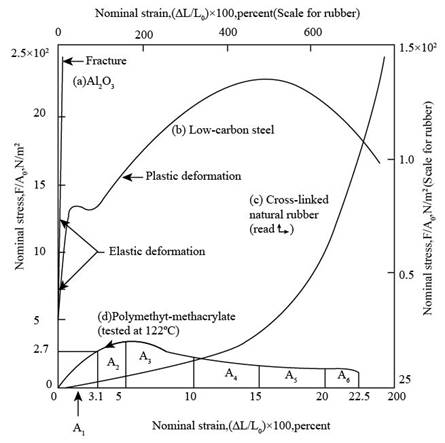

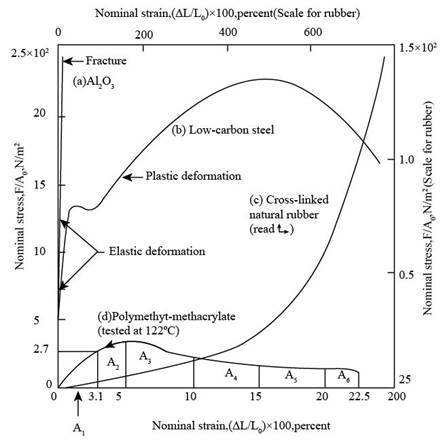

Refer Figure 6.16 “Tensile stress-strain diagram for four different type of materials” from the book “Material Science and Engineering Properties”.

The value of change is stress for PMMA is

Substitute

Conclusion:

Thus, the tangent elastic modulus at zero strain is

(b)

The yield stress of PMMA.

(b)

Answer to Problem 6.19P

The yield stress for PMMA is

Explanation of Solution

Calculation:

Refer Figure 6.16 “Tensile stress-strain diagram for four different type of materials” from the book “Material Science and Engineering Properties”.

The tensile stress diagram for PMMA is shown in figure below.

Figure (1)

The value of the yield stress for PMMA is

Conclusion:

Thus, the yield stress for PMMA is

(c)

The resilience of PMMA.

(c)

Answer to Problem 6.19P

The resilience of PMMA is

Explanation of Solution

Formula Used:

Write the expression for the resilience.

Here,

Calculation:

Substitute

Conclusion:

Thus, the resilience of PMMA is

(d)

The ultimate tensile strength of PMMA.

(d)

Answer to Problem 6.19P

The ultimate tensile strength for PMMA is

Explanation of Solution

Calculation:

The ultimate tensile strength in a stress-strain diagram is obtained by observation of the highest point that is reached by the curve after which the necking of curve starts.

Refer Figure 6.16 “Tensile stress-strain diagram for four different type of materials” from the book “Material Science and Engineering Properties”.

The value of the ultimate tensile strength for PMMA is

Conclusion:

Thus, the ultimate tensile strength for PMMA is

(e)

The toughness of PMMA.

(e)

Answer to Problem 6.19P

The toughness of PMMA is

Explanation of Solution

Formula Used:

Write the expression for the first area.

Here,

Write the expression for the second area.

Here,

Write the expression for the third area.

Here,

Write the expression for the fourth area.

Here,

Write the expression for the fifth area.

Here,

Write the expression for the sixth area.

Here,

Write the expression for the toughness of specimen.

Calculation:

Refer Figure 6.16 “Tensile stress-strain diagram for four different type of materials” from the book “Material Science and Engineering Properties”.

The stress strain diagram for PMMA with sub-divided area is shown below,

Figure (2)

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Conclusion:

Thus, the toughness of PMMA is

Want to see more full solutions like this?

Chapter 6 Solutions

Materials Science And Engineering Properties

- Compare the engineering and true secant elastic moduli for the natural rubber in Example Problem 6.2 at an engineering strain of 6.0. Assume that the deformation is all elastic.arrow_forwardThe results of a tensile test are shown in Table 1.5.2. The test was performed on a metal specimen with a circular cross section. The diameter was 3 8 inch and the gage length (The length over which the elongation is measured) was 2 inches. a. Use the data in Table 1.5.2 to produce a table of stress and strain values. b. Plot the stress-strain data and draw a best-fit curve. c. Compute the, modulus of elasticity from the initial slope of the curve. d. Estimate the yield stress.arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter of 1 2 inch. The gage length (the length over which the elongation is measured) is 2 inches. For a load 13.5 kips, the elongation was 4.6610 3 inches. If the load is assumed to be within the linear elastic rang: of the material, determine the modulus of elasticity.arrow_forward

- The data in Table 1.5.3 were obtained from a tensile test of a metal specimen with a rectangular cross section of 0.2011in.2 in area and a gage length (the length over which the elongation is measured) of 2.000 inches. The specimen was not loaded to failure. a. Generate a table of stress and strain values. b. Plot these values and draw a best-fit line to obtain a stress-strain curve. c. Determine the modulus of elasticity from the slope of the linear portion of the curve. d. Estimate the value of the proportional limit. e. Use the 0.2 offset method to determine the yield stress.arrow_forwardA cylinder with a 6.0 in. diameter and 12.0 in. long is put under a compressive load of 150,000 lbs. The modulus of elasticity for this specimen is 8,000,000 psi. and Poisson’s ratio is 0.35. Calculate the final length and the final diameter of this specimen under this load assuming that the material remains within the linear elastic region.arrow_forwardAn elastoplastic material with strain hardening has the stress– strain relation shown in Figure aside. The modulus of elasticity is 25 x 106 Psi. , yield strength is 70 ksi, and the slope of the strain-hardening portion of the stress–strain diagram is 3 x 106 Psi.a. Calculate the strain that corresponds to a stress of 85 ksi.b. If the 85-ksi stress is removed, calculate the permanent strain.arrow_forward

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning