Concept explainers

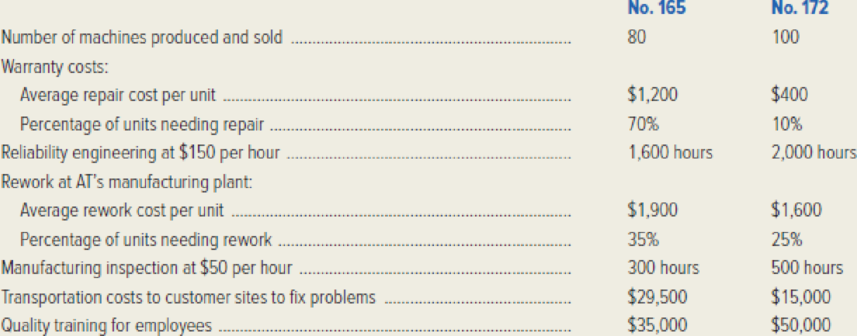

Advanced Technologies (AT) produces two compression machines that are popular with manufacturers of plastics: no. 165 and no. 172. Machine no. 165 has an average selling price of $60,000, whereas no. 172 typically sells for approximately $55,000. The company is very concerned about quality and has provided the following information:

Required:

- 1. Classify the preceding costs as prevention, appraisal, internal failure, or external failure.

- 2. Using the classifications in requirement (1), compute AT’s quality costs for machine no. 165 in dollars and as a percentage of sales revenues. Also calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs.

- 3. Repeat requirement (2) for machine no. 172.

- 4. Comment on your findings, noting whether the company is “investing” its quality expenditures differently for the two machines.

- 5. Quality costs can be classified as observable or hidden. What are hidden quality costs, and how do these costs differ from observable costs?

1.

Classify the given costs of company A as prevention, appraisal, internal failure, or external failure.

Explanation of Solution

Absorption Costing: “Absorption costing is a method that allocates “direct labor, direct materials, fixed manufacturing overhead and variable manufacturing overhead” to products and it is required by GAAP for the purpose of external reporting”.

Variable Costing: Managers frequently use variable costing for internal purposes for taking decision making. The cost of goods manufactured includes direct materials, direct labor, and variable factory overhead. Fixed factory overhead treated as period (fixed) expense.

Classify the given costs of company A as prevention, appraisal, internal failure, or external failure as follows:

| Particular | Type of costs |

| Warranty costs | External failure |

| Reliability engineering | Prevention |

| Rework at AT’s manufacturing plant | Internal failure |

| Manufacturing inspection | Appraisal |

| Transportation costs to customer sites | External failure |

| Quality training for employees | Prevention |

Table (1)

Type of costs:

- A prevention cost is the cost that is used to prevent or minimize the defects. Example: Quality engineering, warranty costs.

- The appraisal cost is the costs that are used to determine whether any defects exist.

- The internal failure costs is the costs that helps to repair the defects (found any) prior to product delivery.

- The external failure cost is the costs that incurred after defective products have been delivered.

2.

Calculate the quality costs of company A for machine no. 165 in dollars and as a percentage of sales revenues, and also compute the percentage of total quality costs of prevention, internal failure, appraisal, and external failure costs.

Explanation of Solution

Calculate the quality costs of company A for machine no. 165 in dollars and as a percentage of sales revenues as follows:

| Company S | ||||

| Quality-Cost Report for Machine 165 | ||||

| For the Month of May | ||||

| Particulars | Units or hours (A) | Cost per unit (B) | Total cost | Percentage of Sales |

| Sales revenue: | 80 units | $60,000 | $4,800,000 | |

| Prevention: | ||||

| Reliability engineering | 1,600 hours | $150 | $ 240,000 | |

| Quality training | 35,000 | |||

| Total (a) | $ 275,000 | 5.73% | ||

| Appraisal (inspection): | 300 hours | $50 | $ 15,000 | 0.31% |

| Total (b) | $ 15,000 | 0.31% | ||

| Internal failure | 80 units | $665 (1) | $ 53,200 | 1.11% |

| Total (c) | $ 53,200 | 1.11% | ||

| External failure: | ||||

| Warranty costs: | 80 units | $840 (2) | $ 67,200 | |

| Transportation to customers | 29,500 | |||

| Total (d) | $ 96,700 | 2.01% | ||

| Total quality costs | $ 439,900 | 9.16% | ||

Table (2)

Compute the percentage of total quality costs of prevention, internal failure, appraisal, and external failure costs as follows:

| Company S | ||

| Quality-Cost Report for Machine 165 | ||

| For the Month of May | ||

| Particulars | Amounts in ($) (a) | Percentage of Total |

| Prevention | $275,000 | 62.51% |

| Appraisal | 15,000 | 3.41% |

| Internal failure | 53,200 | 12.09% |

| External failure | 96,700 | 21.98% |

| Total | $439,900 | |

Table (3)

Working note (1):

Compute the cost per unit of internal failure for machine 165 as follows:

Working note (2):

Compute the warranty cost per unit for machine 165 as follows:

3.

Calculate the quality costs of company A for machine no. 172 in dollars and as a percentage of sales revenues, and also compute the percentage of total quality costs of prevention, internal failure, appraisal, and external failure costs.

Explanation of Solution

Calculate the quality costs of company A for machine no. 172 in dollars and as a percentage of sales revenues as follows:

| Company S | ||||

| Quality-Cost Report for Machine 172 | ||||

| For the Month of May | ||||

| Particulars | Units or hours (A) | Cost per unit (B) | Total cost | Percentage of Sales |

| Sales revenue: | 100 units | $55,000 | $5,500,000 | |

| Prevention: | ||||

| Reliability engineering | 2,000 hours | $150 | $ 300,000 | |

| Quality training | 50,000 | |||

| Total (a) | $ 350,000 | 6.36% | ||

| Appraisal (inspection): | 500 hours | $50 | $ 25,000 | 0.45% |

| Total (b) | $ 25,000 | 0.45% | ||

| Internal failure | 100 units | $400 (3) | $ 40,000 | 0.73% |

| Total (c) | $ 40,000 | 0.73% | ||

| External failure: | ||||

| Warranty costs: | 100 units | $40(4) | $ 4,000 | |

| Transportation to customers | 15,000 | |||

| Total (d) | $ 19,000 | 0.35% | ||

| Total quality costs | $ 434,000 | 7.89% | ||

Table (2)

Compute the percentage of total quality costs of prevention, internal failure, appraisal, and external failure costs as follows:

| Company S | ||

| Quality-Cost Report for Machine 172 | ||

| For the Month of May | ||

| Particulars | Amounts in ($) (a) | Percentage of Total |

| Prevention | $350,000 | 80.65% |

| Appraisal | 25,000 | 5.76% |

| Internal failure | 40,000 | 9.22% |

| External failure | 19,000 | 4.38% |

| Total | $434,900 | |

Table (3)

Working note (3):

Compute the cost per unit of internal failure for machine 172 as follows:

Working note (4):

Compute the warranty cost per unit for machine 172 as follows:

4.

Describe whether the company is “investing” its quality expenditures differently for the two machines.

Explanation of Solution

Yes, the company is “investing” its quality expenditures differently for the two machines. With respect to prevention and appraisal the company spent almost over 86% of the total quality expenditures for machine 172. Whereas, the company spent only 66% (approximately) of the total quality expenditures for machine 165. Thus, the net result is lower internal and external failure costs and, perhaps more important, lower total quality costs as a percentage of sales (7.89% for no. 172 and 9.16% for no. 165). In this case, the company proves the essence of total quality management (TQM) systems when compared with conventional quality control procedures.

5.

Explain the meaning of hidden quality costs, and describe the manner in which the hidden quality costs differ from observable costs.

Explanation of Solution

Prevention, appraisal, internal failure, and external failure costs are the costs that are visible which could be measured and reported. If inferior products make it to the marketplace, it often creates customer dissatisfaction; as a result a loss would occur on the sales of the defective product and perhaps on other goods as well. Thus, the opportunity cost related with lost sales is a hidden quality cost to the company which is very difficult to measure.

Want to see more full solutions like this?

Chapter 8 Solutions

MANAGERIAL ACCOUNTING-ACCESS

- Larsen, Inc., produces two types of electronic parts and has provided the following data: There are four activities: machining, setting up, testing, and purchasing. Required: 1. Calculate the activity consumption ratios for each product. 2. Calculate the consumption ratios for the plantwide rate (direct labor hours). When compared with the activity ratios, what can you say about the relative accuracy of a plantwide rate? Which product is undercosted? 3. What if the machine hours were used for the plantwide rate? Would this remove the cost distortion of a plantwide rate?arrow_forwardStahman, Inc., estimates its hidden external failure costs using the Taguchi loss function. Stahlman produces plastic sheets that vary in thickness and grade. For one of its large-volume products, it was determined that k = 30,000 and T = 0.28 inches in diameter. A sample of four units produced the following values: Required: 1. Calculate the average loss per unit. 2. Assuming that 100,000 units were produced, what is the total hidden cost? 3. Assume that the multiplier for Stahmans hidden external failure costs is six. What are the measured external costs? Explain the difference between measured costs and hidden costs.arrow_forwardBristol is developing material standards for her company. The operations manager wants grade A plastic tops because they are the easiest to work with and are the quality the customers want. Grade B will not work because customers do not want the lower grade, and it takes more time to assemble the product than with grade A materials. Bristol calls several suppliers to get prices for the plastic top. All are within $0.10 of each other. Since the company will use millions of the plastic tops, she decides that the $0.10 difference is important. The supplier who has the lowest price is known for delivering late and low- quality materials. Bristol decides to use the supplier who is $0.04 more but delivers on time and at the right quality. This supplier charges $0.52 per plastic top. Each unit of product requires six plastic tops. What is the standard cost per unit for plastic tops?arrow_forward

- Quincy Farms is a producer of items made from farm products that are distributed to supermarkets. For many years, Quincys products have had strong regional sales on the basis of brand recognition. However, other companies have been marketing similar products in the area, and price competition has become increasingly important. Doug Gilbert, the companys controller, is planning to implement a standard costing system for Quincy and has gathered considerable information from his coworkers on production and direct materials requirements for Quincys products. Doug believes that the use of standard costing will allow Quincy to improve cost control and make better operating decisions. Quincys most popular product is strawberry jam. The jam is produced in 10-gallon batches, and each batch requires six quarts of good strawberries. The fresh strawberries are sorted by hand before entering the production process. Because of imperfections in the strawberries and spoilage, one quart of strawberries is discarded for every four quarts of acceptable berries. Three minutes is the standard direct labor time required for sorting strawberries in order to obtain one quart of strawberries. The acceptable strawberries are then processed with the other ingredients: processing requires 12 minutes of direct labor time per batch. After processing, the jam is packaged in quart containers. Doug has gathered the following information from Joe Adams, Quincys cost accountant, relative to processing the strawberry jam. a. Quincy purchases strawberries at a cost of 0.80 per quart. All other ingredients cost a total of 0.45 per gallon. b. Direct labor is paid at the rate of 9.00 per hour. c. The total cost of direct material and direct labor required to package the jam is 0.38 per quart. Joe has a friend who owns a strawberry farm that has been losing money in recent years. Because of good crops, there has been an oversupply of strawberries, and prices have dropped to 0.50 per quart. Joe has arranged for Quincy to purchase strawberries from his friends farm in hopes that the 0.80 per quart will put his friends farm in the black. Required: 1. Discuss which coworkers Doug probably consulted to set standards. What factors should Doug consider in establishing the standards for direct materials and direct labor? 2. Develop the standard cost sheet for the prime costs of a 10-gallon batch of strawberry jam. 3. Citing the specific standards of the IMA Statement of Ethical Professional Practice described in Chapter 1, explain why Joes behavior regarding the cost information provided to Doug is unethical. (CMA adapted)arrow_forwardPinter Company had the following environmental activities and product information: 1. Environmental activity costs 2. Driver data 3. Other production data Required: 1. Calculate the activity rates that will be used to assign environmental costs to products. 2. Determine the unit environmental and unit costs of each product using ABC. 3. What if the design costs increased to 360,000 and the cost of toxic waste decreased to 750,000? Assume that Solvent Y uses 6,000 out of 12,000 design hours. Also assume that waste is cut by 50 percent and that Solvent Y is responsible for 14,250 of 15,000 pounds of toxic waste. What is the new environmental cost for Solvent Y?arrow_forwardSalem Electronics currently produces two products: a programmable calculator and a tape recorder. A recent marketing study indicated that consumers would react favorably to a radio with the Salem brand name. Owner Kenneth Booth was interested in the possibility. Before any commitment was made, however, Kenneth wanted to know what the incremental fixed costs would be and how many radios must be sold to cover these costs. In response, Betty Johnson, the marketing manager, gathered data for the current products to help in projecting overhead costs for the new product. The overhead costs based on 30,000 direct labor hours follow. (The high-low method using direct labor hours as the independent variable was used to determine the fixed and variable costs.) All depreciation. The following activity data were also gathered: Betty was told that a plantwide overhead rate was used to assign overhead costs based on direct labor hours. She was also informed by engineering that if 20,000 radios were produced and sold (her projection based on her marketing study), they would have the same activity data as the recorders (use the same direct labor hours, machine hours, setups, and so on). Engineering also provided the following additional estimates for the proposed product line: Upon receiving these estimates, Betty did some quick calculations and became quite excited. With a selling price of 26 and just 18,000 of additional fixed costs, only 4,500 units had to be sold to break even. Since Betty was confident that 20,000 units could be sold, she was prepared to strongly recommend the new product line. Required: 1. Reproduce Bettys break-even calculation using conventional cost assignments. How much additional profit would be expected under this scenario, assuming that 20,000 radios are sold? 2. Use an activity-based costing approach, and calculate the break-even point and the incremental profit that would be earned on sales of 20,000 units. 3. Explain why the CVP analysis done in Requirement 2 is more accurate than the analysis done in Requirement 1. What recommendation would you make?arrow_forward

- Moisha is developing material standards for her company. The operations manager wants grade A widgets because they are the easiest to work with and are the quality the customers want. Grade B will not work because customers do not want the lower grade, and it takes more time to assemble the product than with grade A materials. Moisha calls several suppliers to get prices for the widget. All are within $0.05 of each other. Since they will use millions of widgets, she decides that the $0.05 difference is important. The supplier who has the lowest price is known for delivering late and low-quality materials. Moisha decides to use the supplier who is $0.02 more but delivers on time and at the right quality. This supplier charges $0.48 per widget. Each unit of product requires four widgets. What is the standard cost per unit for widgets?arrow_forwardEvans, Inc., has a unit-based costing system. Evanss Miami plant produces 10 different electronic products. The demand for each product is about the same. Although they differ in complexity, each product uses about the same labor time and materials. The plant has used direct labor hours for years to assign overhead to products. To help design engineers understand the assumed cost relationships, the Cost Accounting Department developed the following cost equation. (The equation describes the relationship between total manufacturing costs and direct labor hours; the equation is supported by a coefficient of determination of 60 percent.) Y=5,000,000+30X,whereX=directlaborhours The variable rate of 30 is broken down as follows: Because of competitive pressures, product engineering was given the charge to redesign products to reduce the total cost of manufacturing. Using the above cost relationships, product engineering adopted the strategy of redesigning to reduce direct labor content. As each design was completed, an engineering change order was cut, triggering a series of events such as design approval, vendor selection, bill of materials update, redrawing of schematic, test runs, changes in setup procedures, development of new inspection procedures, and so on. After one year of design changes, the normal volume of direct labor was reduced from 250,000 hours to 200,000 hours, with the same number of products being produced. Although each product differs in its labor content, the redesign efforts reduced the labor content for all products. On average, the labor content per unit of product dropped from 1.25 hours per unit to one hour per unit. Fixed overhead, however, increased from 5,000,000 to 6,600,000 per year. Suppose that a consultant was hired to explain the increase in fixed overhead costs. The consultants study revealed that the 30 per hour rate captured the unit-level variable costs; however, the cost behavior of other activities was quite different. For example, setting up equipment is a step-fixed cost, where each step is 2,000 setup hours, costing 90,000. The study also revealed that the cost of receiving goods is a function of the number of different components. This activity has a variable cost of 2,000 per component type and a fixed cost that follows a step-cost pattern. The step is defined by 20 components with a cost of 50,000 per step. Assume also that the consultant indicated that the design adopted by the engineers increased the demand for setups from 20,000 setup hours to 40,000 setup hours and the number of different components from 100 to 250. The demand for other non-unit-level activities remained unchanged. The consultant also recommended that management take a look at a rejected design for its products. This rejected design increased direct labor content from 250,000 hours to 260,000 hours, decreased the demand for setups from 20,000 hours to 10,000 hours, and decreased the demand for purchasing from 100 component types to 75 component types, while the demand for all other activities remained unchanged. Required: 1. Using normal volume, compute the manufacturing cost per labor hour before the year of design changes. What is the cost per unit of an average product? 2. Using normal volume after the one year of design changes, compute the manufacturing cost per hour. What is the cost per unit of an average product? 3. Before considering the consultants study, what do you think is the most likely explanation for the failure of the design changes to reduce manufacturing costs? Now use the information from the consultants study to explain the increase in the average cost per unit of product. What changes would you suggest to improve Evanss efforts to reduce costs? 4. Explain why the consultant recommended a second look at a rejected design. Provide computational support. What does this tell you about the strategic importance of cost management?arrow_forwardKelson Sporting Equipment, Inc., makes two types of baseball gloves: a regular model and a catchers model. The firm has 900 hours of production time available in its cutting and sewing department, 300 hours available in its finishing department, and 100 hours available in its packaging and shipping department. The production time requirements and the profit contribution per glove are given in the following table: Assuming that the company is interested in maximizing the total profit contribution, answer the following: a. What is the linear programming model for this problem? b. Develop a spreadsheet model and find the optimal solution using Excel Solver. How many of each model should Kelson manufacture? c. What is the total profit contribution Kelson can earn with the optimal production quantities? d. How many hours of production time will be scheduled in each department? e. What is the slack time in each department?arrow_forward

- Anderson Company has the following departmental manufacturing structure for one of its products: After some study, the production manager of Anderson recommended the following revised cellular manufacturing approach: Required: 1. Calculate the total time it takes to produce a batch of 20 units using Andersons traditional departmental structure. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. What if the processing times of molding, welding, and assembly are all reduced to six minutes each? What is the production rate now, and how long will it take to produce a batch of 20 units?arrow_forwardThe Chocolate Baker specializes in chocolate baked goods. The firm has long assessed the profitability of a product line by comparing revenues to the cost of goods sold. However, Barry White, the firms new accountant, wants to use an activity-based costing system that takes into consideration the cost of the delivery person. Following are activity and cost information relating to two of Chocolate Bakers major products: Using activity-based costing, which of the following statements is correct? a. The muffins are 2,000 more profitable. b. The cheesecakes are 75 more profitable. c. The muffins are 1,925 more profitable. d. The muffins have a higher profitability as a percentage of sales and, therefore, are more advantageous.arrow_forwardFreidrich is working with the operations manager to determine what the standard material cost is for a spice chest. He has watched the process from start to finish and taken detailed notes on what material is used. The easiest material to measure is the wood. Each chest uses 5 board feet and produces 1.5 feet of scrap. He is not sure what to do with the scrap that is produced; the company cannot buy the boards in any other dimensions. What amount of materials should be included in the standard for material costs?arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning