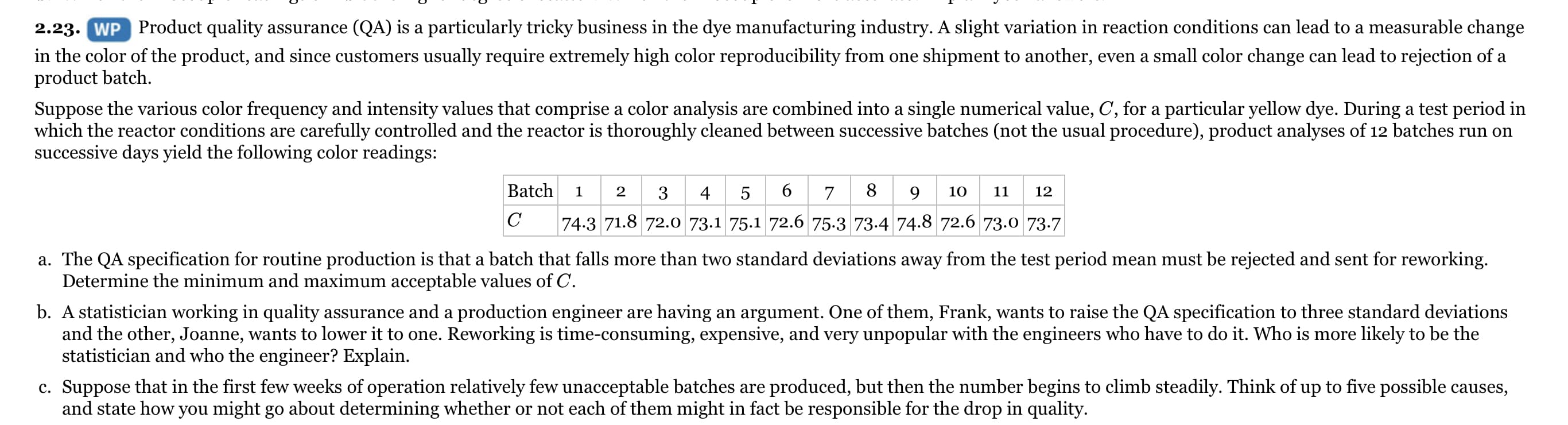

2.23. WP Product quality assurance (QA) is a particularly tricky business in the dye manufacturing industry. A slight variation in reaction conditions can lead to a measurable change in the color of the product, and since customers usually require extremely high color reproducibility from one shipment to another, even a small color change can lead to rejection of a product batch. Suppose the various color frequency and intensity values that comprise a color analysis are combined into a single numerical value, C, for a particular yellow dye. During a test period in which the reactor conditions are carefully controlled and the reactor is thoroughly cleaned between successive batches (not the usual procedure), product analyses of 12 batches run on successive days yield the following color readings: Batch 1 2 3 4 10 11 12 74.3 71.8 72.0 73.1 75.1 72.6 75-3 73.4 74.8 72.6 73.0 73-7 The QA specification for routine production is that a batch that falls more than two standard deviations away from the test period mean must be rejected and sent for reworking. Determine the minimum and maximum acceptable values of C. b. A statistician working in quality assurance and a production engineer are having an argument. One of them, Frank, wants to raise the QA specification to three standard deviations and the other, Joanne, wants to lower it to one. Reworking is time-consuming, expensive, and very unpopular with the engineers who have to do it. Who is more likely to be the statistician and who the engineer? Explain. c. Suppose that in the first few weeks of operation relatively few unacceptable batches are produced, but then the number begins to climb steadily. Think of up to five possible causes, and state how you might go about determining whether or not each of them might in fact be responsible for the drop in quality.

2.23. WP Product quality assurance (QA) is a particularly tricky business in the dye manufacturing industry. A slight variation in reaction conditions can lead to a measurable change in the color of the product, and since customers usually require extremely high color reproducibility from one shipment to another, even a small color change can lead to rejection of a product batch. Suppose the various color frequency and intensity values that comprise a color analysis are combined into a single numerical value, C, for a particular yellow dye. During a test period in which the reactor conditions are carefully controlled and the reactor is thoroughly cleaned between successive batches (not the usual procedure), product analyses of 12 batches run on successive days yield the following color readings: Batch 1 2 3 4 10 11 12 74.3 71.8 72.0 73.1 75.1 72.6 75-3 73.4 74.8 72.6 73.0 73-7 The QA specification for routine production is that a batch that falls more than two standard deviations away from the test period mean must be rejected and sent for reworking. Determine the minimum and maximum acceptable values of C. b. A statistician working in quality assurance and a production engineer are having an argument. One of them, Frank, wants to raise the QA specification to three standard deviations and the other, Joanne, wants to lower it to one. Reworking is time-consuming, expensive, and very unpopular with the engineers who have to do it. Who is more likely to be the statistician and who the engineer? Explain. c. Suppose that in the first few weeks of operation relatively few unacceptable batches are produced, but then the number begins to climb steadily. Think of up to five possible causes, and state how you might go about determining whether or not each of them might in fact be responsible for the drop in quality.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

The problem that is listed below need to be solved and you may access that problem via viewing them through the attached images in this request. **Question Number #2.23**

Transcribed Image Text:2.23. WP Product quality assurance (QA) is a particularly tricky business in the dye manufacturing industry. A slight variation in reaction conditions can lead to a measurable change

in the color of the product, and since customers usually require extremely high color reproducibility from one shipment to another, even a small color change can lead to rejection of a

product batch.

Suppose the various color frequency and intensity values that comprise a color analysis are combined into a single numerical value, C, for a particular yellow dye. During a test period in

which the reactor conditions are carefully controlled and the reactor is thoroughly cleaned between successive batches (not the usual procedure), product analyses of 12 batches run on

successive days yield the following color readings:

Batch

1 2 3

4

10

11

12

74.3 71.8 72.0 73.1 75.1 72.6 75-3 73.4 74.8 72.6 73.0 73-7

The QA specification for routine production is that a batch that falls more than two standard deviations away from the test period mean must be rejected and sent for reworking.

Determine the minimum and maximum acceptable values of C.

b. A statistician working in quality assurance and a production engineer are having an argument. One of them, Frank, wants to raise the QA specification to three standard deviations

and the other, Joanne, wants to lower it to one. Reworking is time-consuming, expensive, and very unpopular with the engineers who have to do it. Who is more likely to be the

statistician and who the engineer? Explain.

c. Suppose that in the first few weeks of operation relatively few unacceptable batches are produced, but then the number begins to climb steadily. Think of up to five possible causes,

and state how you might go about determining whether or not each of them might in fact be responsible for the drop in quality.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The