Why might some workers prefer not to work in a lean production environment? Why might some managers resist a change from a more traditional mode of production to lean production? Important note: please refer to the given lesson in the photos attached. Use it as a basis. Thank you

Why might some workers prefer not to work in a lean production environment? Why might some managers resist a change from a more traditional mode of production to lean production? Important note: please refer to the given lesson in the photos attached. Use it as a basis. Thank you

Chapter1: Taking Risks And Making Profits Within The Dynamic Business Environment

Section: Chapter Questions

Problem 1CE

Related questions

Question

Why might some workers prefer not to work in a lean production environment? Why might some managers resist a change from a more traditional mode of production to lean production?

Important note: please refer to the given lesson in the photos attached. Use it as a basis. Thank you

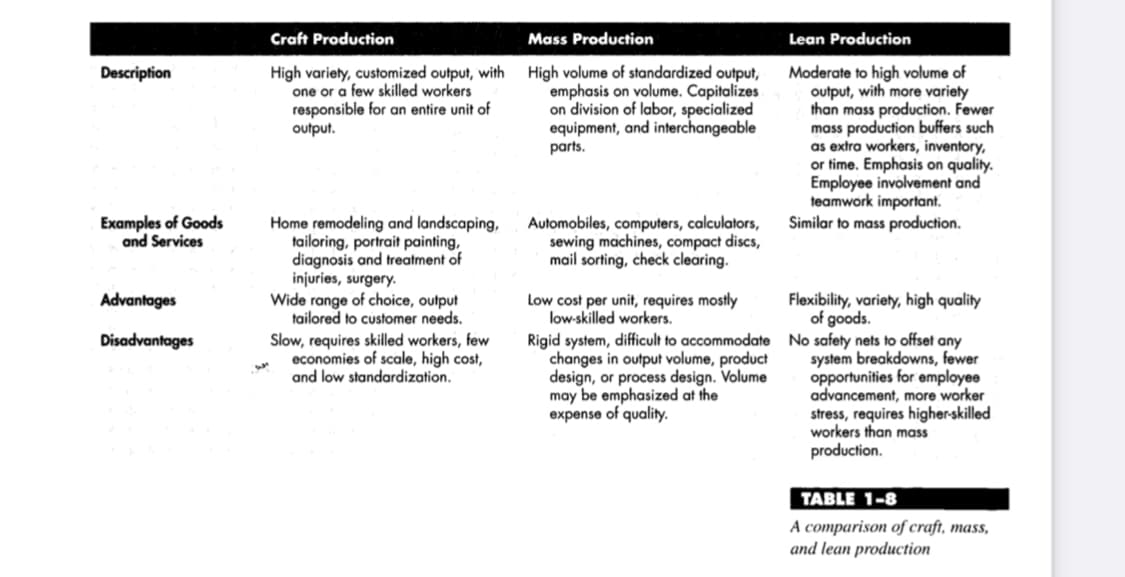

Transcribed Image Text:Description

Examples of Goods

and Services

Advantages

Disadvantages

w

Craft Production

High variety, customized output, with

one or a few skilled workers

responsible for an entire unit of

output.

Home remodeling and landscaping,

tailoring, portrait painting,

diagnosis and treatment of

injuries, surgery.

Wide range of choice, output

tailored to customer needs.

Slow, requires skilled workers, few

economies of scale, high cost,

and low standardization.

Mass Production

High volume of standardized output,

emphasis on volume. Capitalizes

on division of labor, specialized

equipment, and interchangeable

parts.

Automobiles, computers, calculators,

sewing machines, compact discs,

mail sorting, check clearing.

Low cost per unit, requires mostly

low-skilled workers.

Rigid system, difficult to accommodate

changes in output volume, product

design, or process design. Volume

may be emphasized at the

expense of quality.

Lean Production

Moderate to high volume of

output, with more variety

than mass production. Fewer

mass production buffers such

as extra workers, inventory,

or time. Emphasis on quality.

Employee involvement and

teamwork important.

Similar to mass production.

Flexibility, variety, high quality

of goods.

No safety nets to offset any

system breakdowns, fewer

opportunities for employee

advancement, more worker

stress, requires higher-skilled

workers than mass

production.

TABLE 1-8

A comparison of craft, mass,

and lean production

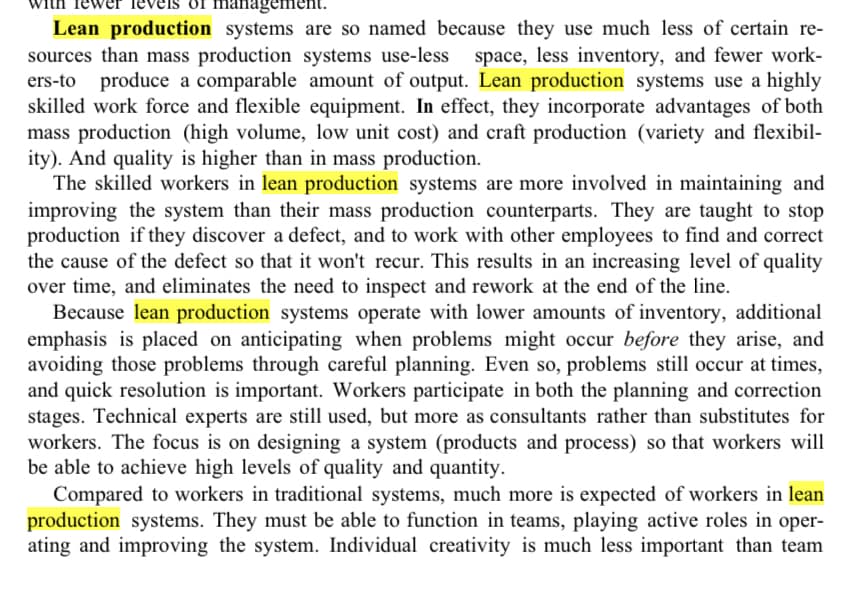

Transcribed Image Text:nanagement.

Lean production systems are so named because they use much less of certain re-

sources than mass production systems use-less space, less inventory, and fewer work-

ers-to produce a comparable amount of output. Lean production systems use a highly

skilled work force and flexible equipment. In effect, they incorporate advantages of both

mass production (high volume, low unit cost) and craft production (variety and flexibil-

ity). And quality is higher than in mass production.

The skilled workers in lean production systems are more involved in maintaining and

improving the system than their mass production counterparts. They are taught to stop

production if they discover a defect, and to work with other employees to find and correct

the cause of the defect so that it won't recur. This results in an increasing level of quality

over time, and eliminates the need to inspect and rework at the end of the line.

Because lean production systems operate with lower amounts of inventory, additional

emphasis is placed on anticipating when problems might occur before they arise, and

avoiding those problems through careful planning. Even so, problems still occur at times,

and quick resolution is important. Workers participate in both the planning and correction

stages. Technical experts are still used, but more as consultants rather than substitutes for

workers. The focus is on designing a system (products and process) so that workers will

be able to achieve high levels of quality and quantity.

Compared to workers in traditional systems, much more is expected of workers in lean

production systems. They must be able to function in teams, playing active roles in oper-

ating and improving the system. Individual creativity is much less important than team

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Understanding Business

Management

ISBN:

9781259929434

Author:

William Nickels

Publisher:

McGraw-Hill Education

Management (14th Edition)

Management

ISBN:

9780134527604

Author:

Stephen P. Robbins, Mary A. Coulter

Publisher:

PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract…

Management

ISBN:

9781305947412

Author:

Cliff Ragsdale

Publisher:

Cengage Learning

Understanding Business

Management

ISBN:

9781259929434

Author:

William Nickels

Publisher:

McGraw-Hill Education

Management (14th Edition)

Management

ISBN:

9780134527604

Author:

Stephen P. Robbins, Mary A. Coulter

Publisher:

PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract…

Management

ISBN:

9781305947412

Author:

Cliff Ragsdale

Publisher:

Cengage Learning

Management Information Systems: Managing The Digi…

Management

ISBN:

9780135191798

Author:

Kenneth C. Laudon, Jane P. Laudon

Publisher:

PEARSON

Business Essentials (12th Edition) (What's New in…

Management

ISBN:

9780134728391

Author:

Ronald J. Ebert, Ricky W. Griffin

Publisher:

PEARSON

Fundamentals of Management (10th Edition)

Management

ISBN:

9780134237473

Author:

Stephen P. Robbins, Mary A. Coulter, David A. De Cenzo

Publisher:

PEARSON