Concept explainers

a)

To develop: A net requirements plan for items.

Introduction:

Net requirements plan:

The net requirements plan is the plan which is established on the gross requirements plan formed by deducting the stock on and the

a)

Explanation of Solution

Given information:

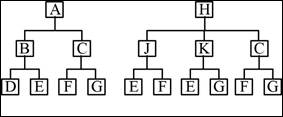

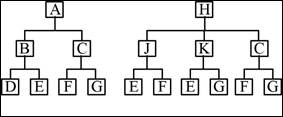

Product structure:

| Period | 8 | 9 | 10 | 11 | 12 |

| Gross requirements: A | 100 | 50 | 150 | ||

| Gross requirements: H | 100 | 50 |

Inventory and lead time:

| Item | A | B | C | D | E | F | G | H | J | K |

| Lead time | 1 | 2 | 2 | 1 | 2 | 2 | 1 | 1 | 2 | 2 |

| On hand | 0 | 100 | 50 | 50 | 75 | 75 | 75 | 0 | 100 | 100 |

- 1 assembly for each item

Item A:

| Week | ||||||||||||

| Item A | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | 150 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | 0 | |||||||||

| Net requirement | 100 | 50 | 150 | |||||||||

| Planned order receipt | 100 | 50 | 150 | |||||||||

| Planned order release | 100 | 50 | 150 | |||||||||

Week 8:

The gross requirement is 100 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 8.

Week 10:

The gross requirement is 50 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 9 which will be the planned order receipt in week 10.

Week 12:

The gross requirement is 150 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 1 week. Therefore, the planned order release will be 150 in week 11 which will be the planned order receipt in week 12.

Item H:

| Week | ||||||||||||

| Item H | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | ||||||||||

| Net requirement | 100 | 50 | ||||||||||

| Planned order receipt | 100 | 50 | ||||||||||

| Planned order release | 100 | 50 | ||||||||||

Week 9:

The gross requirement is 100 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 1000. The lead time is 1 week. Therefore, the planned order release will be 100 in week 8 which will be the planned order receipt in week 10.

Week 11:

The gross requirement is 50 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 9 which will be the planned order receipt in week 11.

Item B:

| Week | ||||||||||||

| Item B | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | 150 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | 0 | |||||||||

| Net requirement | 0 | 50 | 150 | |||||||||

| Planned order receipt | 50 | 150 | ||||||||||

| Planned order release | 50 | 150 | ||||||||||

Week 7:

The gross requirement is 100 (1 assembly) derived from planned order release of A. The on hand inventory is 100. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 9:

The gross requirement is 50 (1 assembly) derived from the planned order release of A. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 7 which will be the planned order receipt in week 9.

Week 11:

The gross requirement is 150 (1 assembly) derived from planned order release of A. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 2 weeks. Therefore, the planned order release will be 150 in week 9 which will be the planned order receipt in week 11.

Item C:

| Week | ||||||||||||

| Item C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 100 | 50 | 50 | 150 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (50) | 50 | 0 | 0 | 0 | 0 | |||||||

| Net requirement | 50 | 100 | 50 | 50 | 150 | |||||||

| Planned order receipt | 50 | 100 | 50 | 50 | 150 | |||||||

| Planned order release | 50 | 100 | 50 | 50 | 150 | |||||||

Week 7:

The gross requirement is 100 (1 assembly) derived from planned order release of A. The on hand inventory is 50. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 5 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of H. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 50 (1 assembly) derived from the planned order release of A. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 7 which will be the planned order receipt in week 9.

Week 10:

The gross requirement is 50 (1 assembly) derived from planned order release of H. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 8 which will be the planned order receipt in week 10.

Week 11:

The gross requirement is 150 (1 assembly) derived from planned order release of A. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 2 weeks. Therefore, the planned order release will be 150 in week 9 which will be the planned order receipt in week 11.

Item J:

| Week | ||||||||||||

| Item J | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | ||||||||||

| Net requirement | 0 | 50 | ||||||||||

| Planned order receipt | 0 | 50 | ||||||||||

| Planned order release | 50 | |||||||||||

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of H. The on hand inventory is 100. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 10:

The gross requirement is 50 (1 assembly) derived from the planned order release of H. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 8 which will be the planned order receipt in week 10.

Item K:

| Week | ||||||||||||

| Item K | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | ||||||||||

| Net requirement | 0 | 50 | ||||||||||

| Planned order receipt | 50 | |||||||||||

| Planned order release | 50 | |||||||||||

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of H. The on hand inventory is 100. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 10:

The gross requirement is 50 (1 assembly) derived from the planned order release of H. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 8 which will be the planned order receipt in week 10.

Item D:

| Week | ||||||||||||

| Item D | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 150 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (50) | 50 | 0 | ||||||||||

| Net requirement | 150 | |||||||||||

| Planned order receipt | 150 | |||||||||||

| Planned order release | 150 | |||||||||||

Week 7:

The gross requirement is 50 (1 assembly) derived from planned order release of B. The on hand inventory is 500. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 9:

The gross requirement is 150 (1 assembly) derived from the planned order release of B. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 1 week. Therefore, the planned order release will be 150 in week 8 which will be the planned order receipt in week 9.

Item E:

| Week | ||||||||||||

| Item E | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 100 | 150 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 25 | 0 | |||||||||

| Net requirement | 0 | 75 | 150 | |||||||||

| Planned order receipt | 75 | 150 | ||||||||||

| Planned order release | 75 | 150 | ||||||||||

Week 7:

The gross requirement is 50 (1 assembly) derived from planned order release of B. The on hand inventory is 75. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 8:

The gross requirement is 100 (1 assembly) derived from the planned order release of J and K. The on hand inventory is 25. Hence, the net requirement is 75. The lead time is 2 weeks. Therefore, the planned order release will be 75 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 150 (1 assembly) derived from planned order release of B. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 2 weeks. Therefore, the planned order release will be 150 in week 7 which will be the planned order receipt in week 9.

Item F:

| Week | ||||||||||||

| Item F | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 100 | 50 | 100 | 150 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 25 | 0 | 0 | 0 | |||||||

| Net requirement | 0 | 75 | 50 | 100 | 150 | |||||||

| Planned order receipt | 75 | 50 | 100 | 150 | ||||||||

| Planned order release | 75 | 50 | 100 | 150 | ||||||||

Week 5:

The gross requirement is 50 (1 assembly) derived from planned order release of C. The on hand inventory is 75. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 6:

The gross requirement is 100 (1 assembly) derived from planned order release of C. The on hand inventory is 25. Hence, the net requirement is 75. The lead time is 2 weeks. Therefore, the planned order release will be 75 in week 4 which will be the planned order receipt in week 6.

Week 7:

The gross requirement is 50 (1 assembly) derived from the planned order release of C. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 5 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of C and J. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 150 (1 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 2 weeks. Therefore, the planned order release will be 150 in week 7 which will be the planned order receipt in week 9.

Item G:

| Week | ||||||||||||

| Item G | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 100 | 50 | 100 | 150 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 25 | 0 | 0 | 0 | |||||||

| Net requirement | 0 | 75 | 50 | 100 | 150 | |||||||

| Planned order receipt | 75 | 50 | 100 | 150 | ||||||||

| Planned order release | 75 | 50 | 100 | 150 | ||||||||

Week 5:

The gross requirement is 50 (1 assembly) derived from planned order release of C. The on hand inventory is 75. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 6:

The gross requirement is 100 (1 assembly) derived from planned order release of C. The on hand inventory is 25. Hence, the net requirement is 75. The lead time is 1 week. Therefore, the planned order release will be 75 in week 5 which will be the planned order receipt in week 6.

Week 7:

The gross requirement is 50 (1 assembly) derived from the planned order release of C. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 6 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of C and K. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 150 (1 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 1 week. Therefore, the planned order release will be 150 in week 8 which will be the planned order receipt in week 9.

b)

To develop: A net requirements plan for all items.

Introduction:

Net requirements plan:

The net requirements plan is the plan which is established on the gross requirements plan formed by deducting the stock on and the scheduled receipts. If the total requirement is below the safety stock levels, a planned order is made based on the given lot sizing technique.

b)

Explanation of Solution

Given information:

Product structure:

| Period | 8 | 9 | 10 | 11 | 12 |

| Gross requirements: A | 100 | 50 | 150 | ||

| Gross requirements: H | 100 | 50 |

Inventory and lead time:

| Item | A | B | C | D | E | F | G | H | J | K |

| Lead time | 1 | 2 | 2 | 1 | 2 | 2 | 1 | 1 | 2 | 2 |

| On hand | 0 | 100 | 50 | 50 | 75 | 75 | 75 | 0 | 100 | 100 |

- 1 assembly for each item

- 2 assemblies for item B, C and F.

Item A:

| Week | ||||||||||||

| Item A | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | 150 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | 0 | |||||||||

| Net requirement | 100 | 50 | 150 | |||||||||

| Planned order receipt | 100 | 50 | 150 | |||||||||

| Planned order release | 100 | 50 | 150 | |||||||||

Week 8:

The gross requirement is 100 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 8.

Week 10:

The gross requirement is 50 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 9 which will be the planned order receipt in week 10.

Week 12:

The gross requirement is 150 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 1 week. Therefore, the planned order release will be 150 in week 11 which will be the planned order receipt in week 12.

Item H:

| Week | ||||||||||||

| Item H | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | ||||||||||

| Net requirement | 100 | 50 | ||||||||||

| Planned order receipt | 100 | 50 | ||||||||||

| Planned order release | 100 | 50 | ||||||||||

Week 9:

The gross requirement is 100 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 1000. The lead time is 1 week. Therefore, the planned order release will be 100 in week 8 which will be the planned order receipt in week 10.

Week 11:

The gross requirement is 50 (1 assembly). The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 9 which will be the planned order receipt in week 11.

Item B:

| Week | ||||||||||||

| Item B | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 200 | 100 | 300 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | 0 | |||||||||

| Net requirement | 100 | 100 | 300 | |||||||||

| Planned order receipt | 100 | 100 | 300 | |||||||||

| Planned order release | 100 | 100 | 300 | |||||||||

Week 7:

The gross requirement is 200 (2 assembly) derived from planned order release of A. The on hand inventory is 100. Hence, the net requirement is 100. Therefore, the planned order release will be 100 in week 5 which will be the planned order receipt in week 7.

Week 9:

The gross requirement is 100 (2 assembly) derived from the planned order release of A. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 9.

Week 11:

The gross requirement is 300 (2 assembly) derived from planned order release of A. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 2 weeks. Therefore, the planned order release will be 300 in week 9 which will be the planned order receipt in week 11.

Item C:

| Week | ||||||||||||

| Item C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 200 | 200 | 100 | 100 | 300 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (50) | 50 | 0 | 0 | 0 | 0 | |||||||

| Net requirement | 150 | 200 | 100 | 100 | 300 | |||||||

| Planned order receipt | 150 | 200 | 100 | 100 | 300 | |||||||

| Planned order release | 150 | 200 | 100 | 100 | 300 | |||||||

Week 7:

The gross requirement is 200 (2 assembly) derived from planned order release of A. The on hand inventory is 50. Hence, the net requirement is 150. The lead time is 2 weeks. Therefore, the planned order release will be 150 in week 5 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 200 (2 assembly) derived from planned order release of H. The on hand inventory is 0. Hence, the net requirement is 200. The lead time is 2 weeks. Therefore, the planned order release will be 200 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 100 (2 assembly) derived from the planned order release of A. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 9.

Week 10:

The gross requirement is 100 (2 assembly) derived from planned order release of H. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 8 which will be the planned order receipt in week 10.

Week 11:

The gross requirement is 300 (2 assembly) derived from planned order release of A. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 2 weeks. Therefore, the planned order release will be 300 in week 9 which will be the planned order receipt in week 11.

Item J:

| Week | ||||||||||||

| Item J | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | ||||||||||

| Net requirement | 0 | 50 | ||||||||||

| Planned order receipt | 0 | 50 | ||||||||||

| Planned order release | 50 | |||||||||||

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of H. The on hand inventory is 100. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 10:

The gross requirement is 50 (1 assembly) derived from the planned order release of H. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 8 which will be the planned order receipt in week 10.

Item K:

| Week | ||||||||||||

| Item K | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 50 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (100) | 100 | 0 | ||||||||||

| Net requirement | 0 | 50 | ||||||||||

| Planned order receipt | 50 | |||||||||||

| Planned order release | 50 | |||||||||||

Week 8:

The gross requirement is 100 (1 assembly) derived from planned order release of H. The on hand inventory is 100. Hence, the net requirement is 0. Therefore, there will be no planned order release.

Week 10:

The gross requirement is 50 (1 assembly) derived from the planned order release of H. The on hand inventory is 0. Hence, the net requirement is 50. The lead time is 2 weeks. Therefore, the planned order release will be 50 in week 8 which will be the planned order receipt in week 10.

Item D:

| Week | ||||||||||||

| Item D | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 100 | 300 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (50) | 50 | 0 | 0 | |||||||||

| Net requirement | 50 | 100 | 300 | |||||||||

| Planned order receipt | 50 | 100 | 300 | |||||||||

| Planned order release | 50 | 100 | 300 | |||||||||

Week 6:

The gross requirement is 100 (1 assembly) derived from the planned order release of B. The on hand inventory is 50. Hence, the net requirement is 50. The lead time is 1 week. Therefore, the planned order release will be 50 in week 5 which will be the planned order receipt in week 6.

Week 8:

The gross requirement is 100 (1 assembly) derived from the planned order release of B. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 7 which will be the planned order receipt in week 8.

Week 8:

The gross requirement is 300 (1 assembly) derived from the planned order release of B. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 1 week. Therefore, the planned order release will be 300 in week 9 which will be the planned order receipt in week 10.

Item E:

| Week | ||||||||||||

| Item E | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 100 | 100 | 300 | ||||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 0 | 0 | 0 | ||||||||

| Net requirement | 25 | 100 | 100 | 300 | ||||||||

| Planned order receipt | 25 | 100 | 100 | 300 | ||||||||

| Planned order release | 25 | 100 | 100 | 300 | ||||||||

Week 5:

The gross requirement is 100 (1 assembly) derived from planned order release of B. The on hand inventory is 75. Hence, the net requirement is 25. The lead time is 2 weeks. Therefore, the planned order release will be 25 in week 3 which will be the planned order receipt in week 5.

Week 7:

The gross requirement is 100 (1 assembly) derived from planned order release of B. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 5 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 100 (1 assembly) derived from the planned order release of J and K. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 300 (1 assembly) derived from planned order release of B. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 2 weeks. Therefore, the planned order release will be 300 in week 7 which will be the planned order receipt in week 9.

Item F:

| Week | ||||||||||||

| Item F | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 300 | 400 | 200 | 300 | 600 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 0 | 0 | 0 | 0 | |||||||

| Net requirement | 225 | 400 | 200 | 300 | 600 | |||||||

| Planned order receipt | 225 | 400 | 200 | 300 | 600 | |||||||

| Planned order release | 225 | 400 | 200 | 300 | 600 | |||||||

Week 5:

The gross requirement is 300 (2 assembly) derived from planned order release of C. The on hand inventory is 75. Hence, the net requirement is 225. The lead time is 2 weeks. Therefore, the planned order release will be 225 in week 3 which will be the planned order receipt in week 5.

Week 6:

The gross requirement is 400 (2 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 400. The lead time is 2 weeks. Therefore, the planned order release will be 400 in week 4 which will be the planned order receipt in week 6.

Week 7:

The gross requirement is 200 (2 assembly) derived from the planned order release of C. The on hand inventory is 0. Hence, the net requirement is 200. The lead time is 2 weeks. Therefore, the planned order release will be 200 in week 5 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 300 (2 assembly) derived from planned order release of C and J. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 2 weeks. Therefore, the planned order release will be 300 in week 6 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 600 (2 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 600. The lead time is 2 weeks. Therefore, the planned order release will be 600 in week 7 which will be the planned order receipt in week 9.

Item G:

| Week | ||||||||||||

| Item G | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 150 | 200 | 100 | 150 | 300 | |||||||

| Scheduled receipt | ||||||||||||

| On hand (75) | 75 | 0 | 0 | 0 | 0 | |||||||

| Net requirement | 75 | 200 | 100 | 150 | 300 | |||||||

| Planned order receipt | 75 | 200 | 100 | 150 | 300 | |||||||

| Planned order release | 75 | 200 | 100 | 150 | 300 | |||||||

Week 5:

The gross requirement is 150 (1 assembly) derived from planned order release of C. The on hand inventory is 75. Hence, the net requirement is 75. The lead time is 1 week. Therefore, the planned order release will be 75 in week 4 which will be the planned order receipt in week 5.

Week 6:

The gross requirement is 200 (1 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 200. The lead time is 1 week. Therefore, the planned order release will be 200 in week 5 which will be the planned order receipt in week 6.

Week 7:

The gross requirement is 100 (1 assembly) derived from the planned order release of C. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 6 which will be the planned order receipt in week 7.

Week 8:

The gross requirement is 150 (1 assembly) derived from planned order release of C and K. The on hand inventory is 0. Hence, the net requirement is 150. The lead time is 1 week. Therefore, the planned order release will be 150 in week 7 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 300 (1 assembly) derived from planned order release of C. The on hand inventory is 0. Hence, the net requirement is 300. The lead time is 1 week. Therefore, the planned order release will be 300 in week 8 which will be the planned order receipt in week 9.

Want to see more full solutions like this?

Chapter 14 Solutions

Principles Of Operations Management

- step by step how does one complete an MRP matrix for item xarrow_forward. Complete the following table. Lead time for the part is 2 weeks. The lot size is 100. Whatis the projected available at the end of week 3? When is it planned to release an order?arrow_forwardA partially completed inventory record for the motor subassembly is shown in Figure.a. Complete the last three rows of the record by using the L4L rule.b. Complete the last three rows of the record by using the POQ rule with P = 2.c. Complete the last three rows of the record by using the POQ rule with P = 2.d. If it costs the company $1 to hold a unit in inventory from one week to the next, and the cost to release an order is $50, which of the lot sizing rules used above will provide the lowest inventory holding + order release cost?arrow_forward

- (Table): The master production schedule calls for production of 15 A in period 1, 5 in period 2, 15 in period 3, 10in period 4, and 15 in period 5.There is a scheduled receipt of 20 A in period 1, 50 B in period 2 and 90 C in period 2. 1. Calculate the MRP-explosion.2. Compare between MRP and ERP. could you please solve both above questions.arrow_forwardIn terms of the frozen part of the calendar, what general trade-offs are included in master scheduling?arrow_forwardDevelop a material requirements plan for component H. Lead times for the end item and each component except B are one week. The lead time for B is three weeks. Sixty units of A are needed at the startof week 8. There are currently 15 units of B on hand and 130 of E on hand, and 50 units of H are inproduction and will be completed by the start of week 2. Lot-for-lot ordering will be used for all items.arrow_forward

- Discuss Material Requirement Planning -MRP with the aid of a diagram What is a Bill-of-Material?arrow_forwardThe following table lists the components needed to assemble an end item, lead times (in weeks), and quantities on hand. Item Lead Time Amount on Hand Direct Components End 2 0 L(2), C(1), K(3) L 2 11 B(2), J(3) C 3 15 G(2), B(2) K 3 20 H(4), B(2) B 2 25 J 3 34 G 3 3 H 2 0 Click here for the Excel Data File a. If 43 units of the end item are to be assembled, how many additional units of B are needed? (Hint: You don’t need to develop an MRP plan.) b. An order for the end item is scheduled to be shipped at the start of week 11. What is the latest week that the order can be started and still be ready to ship on time? (Hint: You don’t need to develop an MRP plan.)arrow_forwardThe BOM for product A is given below:Assume the master schedule calls for 200 units of product A in week 5 and 250 units in week 6. a. Develop a materials plan for this product. b. What actions should be taken immediately? c. Project the inventory ahead for each part. d. If you were suddenly notified that part D will take three weeks to get instead of two weeks, what actions would you take?arrow_forward

- The following table lists the components needed to assemble an end item, the manufacturing or purchase lead times (in weeks) for typical lot sizes, amount on hand, and the direct components of each item and, in brackets, the number of each component for each parent. Item Lead Time Amount onHand DirectComponents End item 1 - L(2), C(1), K(3) L 1 8 B(2), J(3) C 3 14 G(2), B(2) K 3 18 H(4), B(2) B 1 24 J 4 34 G 3 38 H 3 - a. This part of the question is not part of your Connect assignment.b. If 44 units of the end item are to be assembled, how many additional units of B are needed? (You don’t need to develop the MRP tables.)Additional units c. An order for 44 units of the end item is scheduled to be shipped at the start of week 8. What is the latest week that the components of the order can be started and the order still be ready to ship on time? (You don’t need to develop the MRP tables.)The latest weekarrow_forwardA table is assembled using three components, as shown in the accompanying product structure tree.The company that makes the table wants to ship 100 units at the beginning of day 4, 150 units atthe beginning of day 5, and 200 units at the beginning of day 7. Receipts of 100 wood sections arescheduled at the beginning of day 2. There are 120 legs on hand. There are 60 braces on hand. Leadtimes (in days) for all items are shown in the following table. Prepare a material requirements planusing lot-for-lot ordering.arrow_forwardExplain asn describe what is meant by the material requirements plan in scheduling ?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.