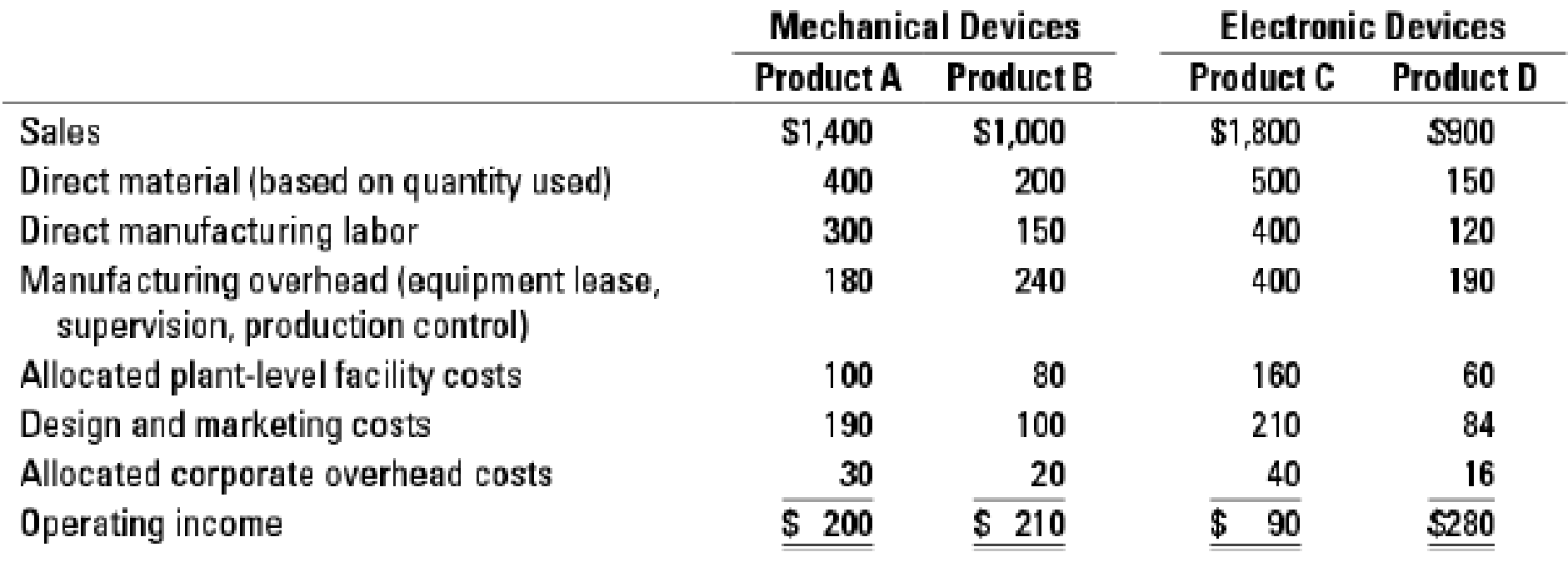

Lean accounting. Reliable Security Devices (RSD) has introduced a just-in-time production process and is considering the adoption of lean accounting principles to support its new production philosophy. The company has two product lines: Mechanical Devices and Electronic Devices. Two individual products are made in each line. Product-line

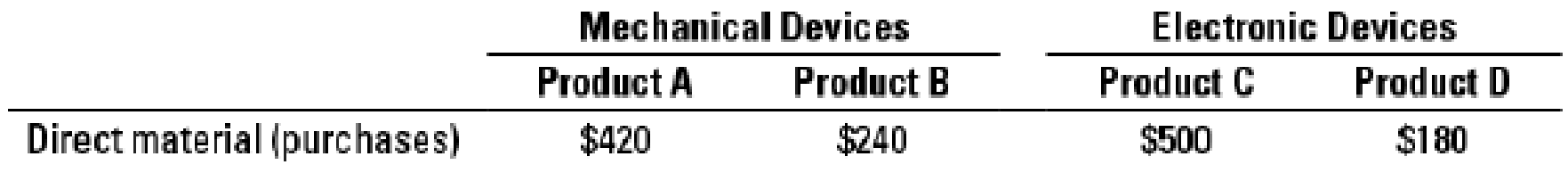

RSD has determined that each of the two product lines represents a distinct value stream. It has also determined that out of the $400,000 ($100,000 + $80,000 + $160,000 + $60,000) plant-level facility costs, product A occupies 22% of the plant’s square footage, product B occupies 18%, product C occupies 36%, and product D occupies 14%. The remaining 10% of square footage is not being used. Finally, RSD has decided that in order to identify inefficiencies, direct material should be expensed in the period it is purchased, rather than when the material is used. According to purchasing records, direct material purchase costs during the period were as follows:

- 1. What are the cost objects in RSD’s lean accounting system?

Required

- 2. Compute operating income for the cost objects identified in requirement 1 using lean accounting principles. What would you compare this operating income against? Comment on your results.

Want to see the full answer?

Check out a sample textbook solution

Chapter 20 Solutions

COST ACCOUNTING

- Reducir, Inc., produces two different types of hydraulic cylinders. Reducir produces a major subassembly for the cylinders in the Cutting and Welding Department. Other parts and the subassembly are then assembled in the Assembly Department. The activities, expected costs, and drivers associated with these two manufacturing processes are given below. Note: In the assembly process, the materials-handling activity is a function of product characteristics rather than batch activity. Other overhead activities, their costs, and drivers are listed below. Other production information concerning the two hydraulic cylinders is also provided: Required: 1. Using a plantwide rate based on machine hours, calculate the total overhead cost assigned to each product and the unit overhead cost. 2. Using activity rates, calculate the total overhead cost assigned to each product and the unit overhead cost. Comment on the accuracy of the plantwide rate. 3. Calculate the global consumption ratios. 4. Calculate the consumption ratios for welding and materials handling (Assembly) and show that two drivers, welding hours and number of parts, can be used to achieve the same ABC product costs calculated in Requirement 2. Explain the value of this simplification. 5. Calculate the consumption ratios for inspection and engineering, and show that the drivers for these two activities also duplicate the ABC product costs calculated in Requirement 2.arrow_forwardSouthward Company has implemented a JIT flexible manufacturing system. John Richins, controller of the company, has decided to reduce the accounting requirements given the expectation of lower inventories. For one thing, he has decided to treat direct labor cost as a part of overhead and to discontinue the detailed direct labor accounting of the past. The company has created two manufacturing cells, each capable of producing a family of products: the radiator cell and the water pump cell. The output of both cells is sold to a sister division and to customers who use the radiators and water pumps for repair activity. Product-level overhead costs outside the cells are assigned to each cell using appropriate drivers. Facility-level costs are allocated to each cell on the basis of square footage. The budgeted direct labor and overhead costs are as follows: The predetermined conversion cost rate is based on available production hours in each cell. The radiator cell has 45,000 hours available for production, and the water pump cell has 27,000 hours. Conversion costs are applied to the units produced by multiplying the conversion rate by the actual time required to produce the units. The radiator cell produced 81,000 units, taking 0.5 hour to produce one unit of product (on average). The water pump cell produced 90,000 units, taking 0.25 hour to produce one unit of product (on average). Other actual results for the year are as follows: All units produced were sold. Any conversion cost variance is closed to Cost of Goods Sold. Required: 1. Calculate the predetermined conversion cost rates for each cell. 2. Prepare journal entries using backflush accounting. Assume two trigger points, with completion of goods as the second trigger point. 3. Repeat Requirement 2, assuming that the second trigger point is the sale of the goods. 4. Explain why there is no need to have a work-in-process inventory account. 5. Two variants of backflush costing were presented in which each used two trigger points, with the second trigger point differing. Suppose that the only trigger point for recognizing manufacturing costs occurs when the goods are sold. How would the entries be listed here? When would this backflush variant be considered appropriate?arrow_forwardLarsen, Inc., produces two types of electronic parts and has provided the following data: There are four activities: machining, setting up, testing, and purchasing. Required: 1. Calculate the activity consumption ratios for each product. 2. Calculate the consumption ratios for the plantwide rate (direct labor hours). When compared with the activity ratios, what can you say about the relative accuracy of a plantwide rate? Which product is undercosted? 3. What if the machine hours were used for the plantwide rate? Would this remove the cost distortion of a plantwide rate?arrow_forward

- Evans, Inc., has a unit-based costing system. Evanss Miami plant produces 10 different electronic products. The demand for each product is about the same. Although they differ in complexity, each product uses about the same labor time and materials. The plant has used direct labor hours for years to assign overhead to products. To help design engineers understand the assumed cost relationships, the Cost Accounting Department developed the following cost equation. (The equation describes the relationship between total manufacturing costs and direct labor hours; the equation is supported by a coefficient of determination of 60 percent.) Y=5,000,000+30X,whereX=directlaborhours The variable rate of 30 is broken down as follows: Because of competitive pressures, product engineering was given the charge to redesign products to reduce the total cost of manufacturing. Using the above cost relationships, product engineering adopted the strategy of redesigning to reduce direct labor content. As each design was completed, an engineering change order was cut, triggering a series of events such as design approval, vendor selection, bill of materials update, redrawing of schematic, test runs, changes in setup procedures, development of new inspection procedures, and so on. After one year of design changes, the normal volume of direct labor was reduced from 250,000 hours to 200,000 hours, with the same number of products being produced. Although each product differs in its labor content, the redesign efforts reduced the labor content for all products. On average, the labor content per unit of product dropped from 1.25 hours per unit to one hour per unit. Fixed overhead, however, increased from 5,000,000 to 6,600,000 per year. Suppose that a consultant was hired to explain the increase in fixed overhead costs. The consultants study revealed that the 30 per hour rate captured the unit-level variable costs; however, the cost behavior of other activities was quite different. For example, setting up equipment is a step-fixed cost, where each step is 2,000 setup hours, costing 90,000. The study also revealed that the cost of receiving goods is a function of the number of different components. This activity has a variable cost of 2,000 per component type and a fixed cost that follows a step-cost pattern. The step is defined by 20 components with a cost of 50,000 per step. Assume also that the consultant indicated that the design adopted by the engineers increased the demand for setups from 20,000 setup hours to 40,000 setup hours and the number of different components from 100 to 250. The demand for other non-unit-level activities remained unchanged. The consultant also recommended that management take a look at a rejected design for its products. This rejected design increased direct labor content from 250,000 hours to 260,000 hours, decreased the demand for setups from 20,000 hours to 10,000 hours, and decreased the demand for purchasing from 100 component types to 75 component types, while the demand for all other activities remained unchanged. Required: 1. Using normal volume, compute the manufacturing cost per labor hour before the year of design changes. What is the cost per unit of an average product? 2. Using normal volume after the one year of design changes, compute the manufacturing cost per hour. What is the cost per unit of an average product? 3. Before considering the consultants study, what do you think is the most likely explanation for the failure of the design changes to reduce manufacturing costs? Now use the information from the consultants study to explain the increase in the average cost per unit of product. What changes would you suggest to improve Evanss efforts to reduce costs? 4. Explain why the consultant recommended a second look at a rejected design. Provide computational support. What does this tell you about the strategic importance of cost management?arrow_forwardWojtek Nakowski has prepared the following list of statements about process cost accounting. Identify each statement as true or false. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Process cost systems are used to apply costs to similar products that are mass-produced in a continuous fashion. A process cost system is used when each finished unit is indistinguishable from another. Companies that produce soft drinks, motion pictures, and computer chips would all use process cost accounting. In a process cost system, costs are tracked by individual jobs. Job-order costing and process costing track different manufacturing cost components. Both job-order costing and process costing account for direct materials, direct labour, and manufacturing overhead. Costs flow through the accounts in the same basic way for both job-order costing and process costing. In a process cost system, only one work in process inventory account is used. In a process cost system, costs are summarized in a job cost sheet. In a…arrow_forwardA new product Zico was recently introduced by Philadelphia Co., in order to complement its other products, Novo and Domo. The accountant used to allocate the indirect cost according to the units produced. With the recent addition of an expanded computer system, Sonata would like to investigate the possibility of implementing ABC. Before making a final decision, management has come to you for advice. You collected the following information regarding manufacturing overhead: Table (1) Mfg. Overhead Mfg. Overhead Allocation bases Costs $ 40,000 $ 45,000 $ 9,000 $ 21,000 Number of set-ups Set-up Ordering materials Handling materials Inspection Number of material orders Number of times material was handled Number of inspection hours $115,000 Table (2) Products Activity Zico Novo Domo Total Number of set-ups 5 20 55 Total Number of material orders 1 2 7 Total Number of times material was handled 1 17 Total Number of inspection hours Number of units produced 3 10 6,000 3,000 1,000 Required: 1.…arrow_forward

- Determine the total costs that each operating segment would be accountable for if the step method is used to allocate support costs; assume support departments are ranked according to their original cost. (Round intermediate calculations to 4 decimal places, e.g. 15.2516 and final answers to 2 decimal places, e.g. 15.25.) Total costs $ Operating Segments Institutional Taythank and Media. 776887.5 Retail 468712.5arrow_forwardTwo years ago, company scientists developed an alloy with all of the properties of the raw materials used in XL-D that generates no wastewater. Some prototype components using the new material were produced and tested and found to be indistinguishable from the old components in every way relating to their fitness for use. The only difference is that the new alloy is more expensive than the old raw material. The company has been test-marketing the newer version of the component, referred to as XL-C, and is currently trying to decide its fate. Manufacturing of both components begins in the Production Department and is completed in the Assembly Department. No other products are produced in the plant. The following information relates to the two components: Units produced Raw material costs per unit Direct labor-hours per unit-Production Direct labor-hours per unit-Assembly Direct labor rate per hour-all labor Machine-hours per unit-Production Machine-hours per unit-Assembly Testing hours…arrow_forwardSusan Mills, Company B's chief accountant, has developed an automated costing system that helps track the cost of production activities. This system is capable of accurately measuring and allocating post-manufacturing activities, such as selling, promotional, and distribution activities, in such a way that Company B gets a more detailed view of its product costs. One of the benefits of this system is that it allows Company B to determine which product lines are more profitable When Susan implemented the new costing system, she realized that the company's current period profits would increase significantly if the new product cost information was used for inventory valuation on the financial statements. Susan has been under intense pressure to improve the company's profits, and this would be a quick and effective way for her to help meet the company's short-term profit goals. As a result, Susan has decided to use the automated costing system to determine the company's profits. 1. Why…arrow_forward

- Mirabile Corporation uses activity-based costing to compute product margins. Overhead costs have already been allocated to the company's three activity cost pools--Processing, Supervising, and Other. The costs in those activity cost pools appear below: Processing Supervising Other Processing costs are assigned to products using machine-hours (MHs) and Supervising costs are assigned to products using the number of batches. The costs in the other activity cost pool are not assigned to products. Activity data appear below: Product MO Product M5 Total $ 3,800 $ 23,800 $ 10,400 MHs (Processing) 9,700 300 10,000 Sales (total) Direct materials (total) Direct labor (total) Batches (Supervising) 500 500 1,000 Finally, sales and direct cost data are combined with Processing and Supervising costs to determine product margins. Product Mº $ 74,100 $ 28,500 $ 27,800 Product M5 $ 89,900 $ 31,400 $ 41,700arrow_forwardSusan Mills, Company B's chief accountant, has developed an automated costing system that helps track the cost of production activities. This system is capable of accurately measuring and allocating post-manufacturing activities, such as selling, promotional, and distribution activities, in such a way where Company B gets a more detailed view of its product costs. One of the benefits of this system is that it allows Company B to determine which product lines are more profitable. When Susan implemented the new costing system, she realized that the company's current period profits would increase significantly if the new product cost information was used for inventory valuation on the financial statements. Susan has been under intense pressure to improve the company's profits, and this would be a quick and effective way for her to help meet the company's short-term profit goals. As a result, Susan has decided to use the automated costing system to determine the company's profits.…arrow_forwardAbsorption costing is a widely used accounting method for costing and reporting on the total production cost of goods or services within an organization. It involves allocating both variable and fixed manufacturing costs to the cost of products. With that in mind, consider the following scenario: ABC Manufacturing Company produces electronic gadgets. In a given accounting period, the company manufactured and sold 10,000 units of their flagship gadget. The following data is available: Direct materials cost per unit: $50 Direct labor cost per unit: $30 Variable manufacturing overhead cost per unit: $20 Fixed manufacturing overhead cost for the period: $50,000 Selling and administrative expenses (all fixed): $30,000 Selling price per gadget: $200 Using absorption costing, calculate the following: A. The total manufacturing cost per unit of the electronic gadget. B. The total cost of goods manufactured during the accounting period. C. The ending inventory value of the manufactured gadgets.…arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub