Concept explainers

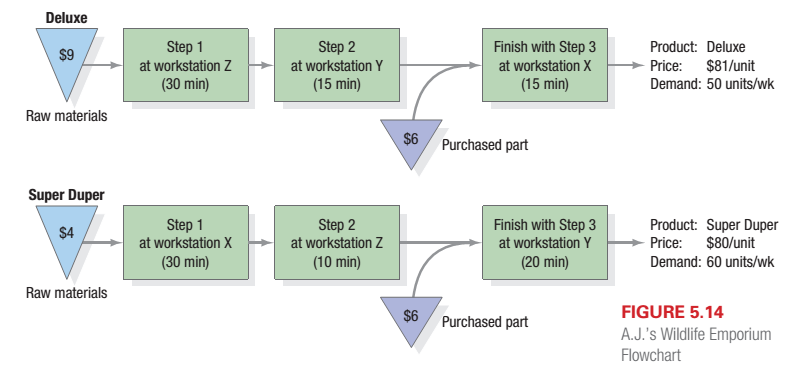

A.J.’s Wildlife Emporium manufactures two unique birdfeeders (Deluxe and Super Duper) that are manufactured and assembled in up to three different workstations

- Using the traditional method, which bases decisions solely on a product’s contribution to profits and overhead, what is the optimal product mix and what is the overall profitability?

- Using the bottleneck-based method, what is the optimal product mix and what is the overall profitability?

Want to see the full answer?

Check out a sample textbook solution

Chapter 5 Solutions

Operations Management: Processes and Supply Chains, Student Value Edition Plus MyLab Operations Management with Pearson eText -- Access Card Package (12th Edition)

Additional Business Textbook Solutions

Operations Management: Sustainability and Supply Chain Management (12th Edition)

Operations Management

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

Operations Management

Operations and Supply Chain Management 9th edition

Business in Action (8th Edition)

- Tailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwindshoe, which sells for $210, contains both gas- and liquid-filled compartments to provide morestability and better protection against knee, foot, and back injuries. Manufacturing the shoesrequires 10 separate tasks. There are 400 minutes available for manufacturing the shoes inthe plant each day. Daily demand is 60. The information for the tasks is as follows: Task Performance Time (In minutes) Task Must Follow This task A 1 ___ B 3 A C 2 B D 4 B E 1 C.D F 3 A G 2 F H 5 G I 1 E,H J 3/25 I 1. What is the theoretical minimum number of work stations required to satisfy this output rate? 2. Allocate the tasks to work stations taking into consideration the precedence requirements and usingthe LOT rule to break ties between feasible tasks.arrow_forwardPlease dont answer in image ormat,Do type. Canine Kennels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see the figure below). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $6 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day, or…arrow_forwardCanine Kernels Company (CKC) manufactures two differenttypes of dog chew toys (A and B, sold in 1,000-count boxes)that are manufactured and assembled on three differentworkstations (W, X, and Y) using a small-batch process (seeFigure 5.12). Batch setup times are negligible. The flowchartdenotes the path each product follows through the manu-facturing process, and each product’s price, demand perweek, and processing times per unit are indicated as well.Purchased parts and raw materials consumed during pro-duction are represented by inverted triangles. CKC can makeand sell up to the limit of its demand per week; no penaltiesare incurred for not being able to meet all the demand. Eachworkstation is staffed by a worker who is dedicated to workon that workstation alone, and is paid $6 per hour. Totallabor costs per week are fixed. Variable overhead costs are$3,500/week. The plant operates one 8-hour shift per day, or40 hours/week. Which of the three workstations, W, X, or Y,has the highest…arrow_forward

- SpikLock makes several lines of metal items. The most recent order has been for 1200 door lock units for an apartment complex developer. The sales and production departments must work together to determine delivery schedules. Each lock unit consists of three components: the knob and faceplate, the actual lock itself, and a set of two keys. Although the processes used in the manufacture of the three components vary, there are three areas where the production manager is concerned about the availability of resources. These three areas, their usage by the three components, and their availability are detailed in the table. Resource Knob and Plate Lock Key (each) Available Brass Alloy 12 5 1 15000 units Machining 18 20 10 36000 minutes Finishing 15 5 1 12000 minutes A quick look at the amounts available confirms that SpikLock does not have the resources to fill this contract. A subcontractor, who can make an unlimited number of each…arrow_forwardBill’s Barbershop has two barbers available to cut customers’hair. Both barbers provide roughly the same experience andskill, but one is just a little bit slower than the other. The pro-cess flow in Figure 5.9 shows that all customers go throughsteps B1 and B2 and then can be served at either of the twobarbers at step B3. The process ends for all customers atstep B4. The numbers in parentheses indicate the minutes ittakes that activity to process a customer. a. How long does it take the average customer to completethis process?b. What single activity is the bottleneck for the entireprocess?c. How many customers can this process serve in an hour?arrow_forwardSteel City Juice is a local company that makes two kinds of juice: orange juice and apple juice.Demand for orange juice is 60 barrels/hr, while demand for apple juice is 40 barrels/hr. The company only has one machine to extract juice from raw fruit. The machine can extract orange juice at a speed of 150 barrels/hr, or apple juice at 120 barrels/hr. Switching from one type to the other requires 30 minutes cleanup time.Please provide a production schedule and an associated process flow diagram that (i) cycles repeatedly through the two kinds, (ii) meets the required demand, and (iii) minimizes the amount of inventory held. (Here it is assumed that the production machine runs 24 hours a day, 7 days a week ) and what is the maximum inventory level of orange juice?arrow_forward

- Tailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwind shoe, which sells for $210, contains both gas- and liquid-filled compartments to provide more stability and better protection against knee, foot, and back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400minutes available for manufacturing the shoes in the plant each day. Daily demand is 62.The information for the tasks is as follows: Task Performance Time (mins) Predecessors A 1 − B 3 A C 1 B D 4 B E 1 C, D F 3 A G 2 F H 5 G I 3 E, H J 2 I a-b) The correct precedence relationship with one of the possible assignments of tasks using the "ranked positionedweight" to workstations is shown in Fig 1, 2 or 3 c) The efficiency of the assembly line with 5 workstations shown in the figure…arrow_forwardTailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwind shoe, which sells for $210, contains both gas- and liquid-filled compartments to provide more stability and better protection against knee, foot, and back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400 minutes available for manufacturing the shoes in the plant each day. Daily demand is 64. The information for the tasks is as follows: Task Performance Time (mins) Predecessors A 1 − B 3 A C 1 B D 4 B E 1 C, D F 3 A G 2 F H 5 G I 1 E, H J 3 I a) The efficiency of the assembly line with 5 workstations shown in the figure chosen above=(enter your response as a percentage rounded to one decimal place). b) The idle time for the assembly line per cycle =minute(s) (enter your…arrow_forwardYost-Perry Industries (YPI) manufactures a mix of affordable guitars (A, B, C) that are fabricated and assembled at four different processing stations (W, X, Y, Z). The operation is a batch process with small setup times that can be considered negligible. The product information (price, weekly demand, and processing times) and process sequences are shown in Figure. Raw materials and purchased parts (shown as a per-unit consumption rate) are represented by inverted triangles. YPI is able to make and sell up to the limit of its demand per week with no penalties incurred for not meeting the full demand. Each workstation is staffed by one highly skilled worker who is dedicated to work on that workstation alone and is paid $15 per hour. The plant operates one 8-hour shift per day and operates on a 5-day work week (i.e., 40 hours of production per person per week). Overhead costs are $9,000/week. Which of the four workstations, W, X, Y, or Z, has the highest aggregate workload, and thus…arrow_forward

- A process is accomplished in 4 sequential steps- S1, S2, S3 and S4. The lead times (in minutes) and the number of resources for every step are indicated in the table below. Sub - Process Time (min) No of resources S1 12 1 S2 8 1 S3 16 1 S4 10 1 Assuming infinite demand, what is the process flow rate? {keep the time dimension as minutes for this, and answer in decimals). Hi all, I do not know how to answer this questions. Please review and advise. Thank youarrow_forwardThe M–N plant manufactures two different products: M and N. Selling prices and weekly market demands are shown in the following diagram. Each product uses raw materials with costs as shown. The plant has three different machines: A, B, and C. Each performs different tasks and can work on only one unit of material at a time. Process times for each task are shown in the diagram. Each machine is available 2,500 minutes per week. There are no "Murphys" (major opportunities for the system to foul up). Setup and transfer times are zero. Demand is constant. Operating expenses (including labor) total a constant $12,000 per week. Raw materials are not included in weekly operating expenses. a. Which machine is the constraint in this plant? multiple choice Machine A Machine C Machine B Incorrectarrow_forwardRegistration at Southern University has always been a time of emotions, commotions and lines. students must move among 4 stations to complete the process. last semester's registration is in fig. 9.20. 450 students moved from the paperwork station (A) to advising (B) and 550 students went directly from (A) to pick up class cards (C). preregistered graduate students went directly to pay (D). A to D is in a linear fashion and the distance from A to B, B to C and C to D is 30feet. a. calculate the movement cost or 'load x distance' of the layout b. provide an improved layout and provide its movement costarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,