Concept explainers

(a)

The work-done in open die forging of cylinder for no friction between the flat dies and the specimen.

(a)

Explanation of Solution

Given:

The initial thickness of the specimen is

The initial radius of the specimen is

The friction coefficient is

Formula used:

The expression for the flow stress is given as,

Here,

The expression for the true strain is given as,

Here,

The expression for the final radius by equating the volume is given as,

The expression for the forging force is given as,

Here,

The expression for the average pressure is given as,

The expression for final height for

The expression for final height for

The expression forfinal height for

The expression for final height for

The expression for final height for

Calculation:

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

| Reduction (in ) | Forging force (in ) | Area under curve (in ) |

| 2.1635 |

Work done can be calculated by calculating the sum of area under the curve.

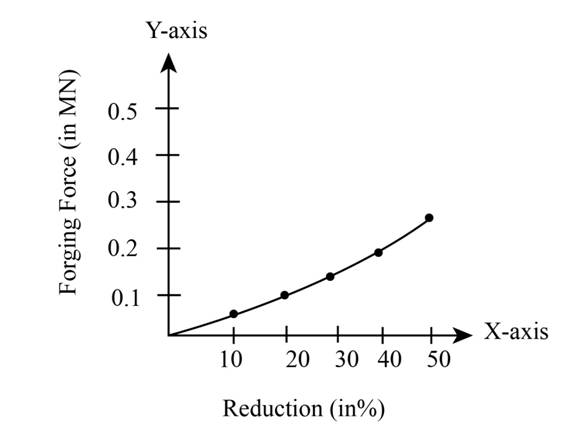

The figure (1) shows the curve between the forging force and reduction in height,

Figure (1)

(b)

The work-done in open die forging of cylinder for

(b)

Explanation of Solution

Given:

The initial thickness of the specimen is

The initial radius of the specimen is

The friction coefficient is

Formula used:

The expression for the flow stress is given as,

Here,

The expression for the true strain is given as,

Here,

The expression for the final radius by equating the volume is given as,

The expression for the forging force is given as,

Here,

The expression for the average pressure is given as,

The expression for final height for

The expression for final height for

The expression forfinal height for

The expression for final height for

The expression for final height for

Calculation:

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

| Reduction (in ) | Forging force (in ) | Area under curve (in ) |

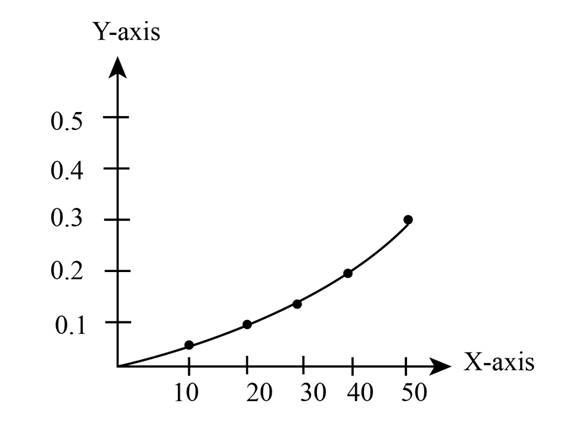

Work done can be calculated by calculating the sum of area under the curve.

The figure (2) shows the curve between the forging force and reduction in height,

Figure (2)

Want to see more full solutions like this?

Chapter 6 Solutions

EBK MANUFACTURING PROCESSES FOR ENGINEE

- A mechanical press is powered by a 23-kW motor and operates at 40 strokes per minute. It uses a flywheel, so that the crankshaft speed does not vary appreciably during the stroke. If the stroke is 150 mm, what is the maxumum const.ant force rhat can be exerted over the entire stroke length?arrow_forwardShow the details of your solutions with correct diagrams and unit analysisarrow_forwardA 10 mm thick plate is rolled to 7 mm thick in a rolling mill using 1000 mm diameter rigid rolls. The neutral point is located at an angle of 0.3 times the bite angle from the exit. What will be the thickness of the plate at the neutral point.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY