Concept explainers

(a)

The expression for average pressure in plain-strain compression with Tresca friction.

(a)

Answer to Problem 6.82P

The expression for average pressure in plain-strain compression with Tresca friction is

Explanation of Solution

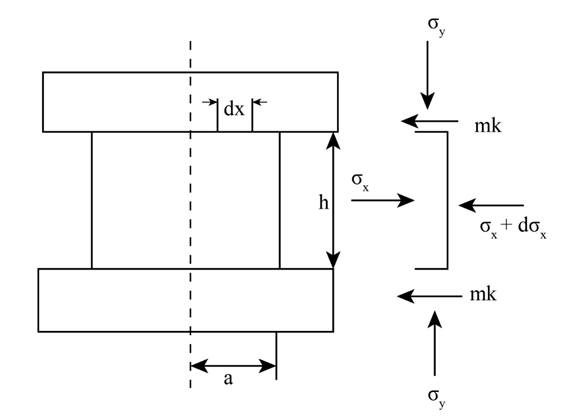

The figure (1) shows the force analysis in forging method,

Figure (1)

Using force balance in x-direction,

Here,

On solving the above equation,

Applying the boundary conditions,

The value of

The normal stress can be calculated by equation (1),

The condition for the die pressure is given as,

Here,

Substitute the values of

For

For

Adding equation (2) and (3),

Conclusion:

Therefore, the expression for average pressure in plain-strain compression with Tresca friction is

(b)

The expression for average pressure in plain-strain compression with sticking friction with

(b)

Answer to Problem 6.82P

The expression for average pressure in plain-strain compression with Sticking friction is

Explanation of Solution

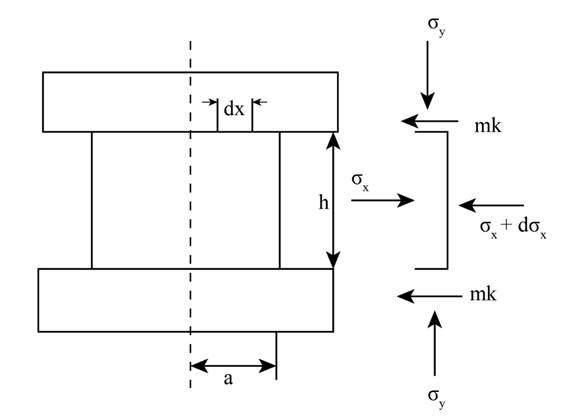

The figure (2) shows the force analysis in forging method,

Figure (2)

Using force balance in x-direction,

Here,

On solving the above equation,

Applying the boundary conditions,

The value of

The normal stress can be calculated by equation (1),

The condition for the die pressure is given as,

Here,

Substitute the values of

For

For

Adding equation (2) and (3),

For sticking friction

Conclusion:

Therefore, the expression for average pressure in plain-strain compression with Sticking friction is

Want to see more full solutions like this?

Chapter 6 Solutions

EBK MANUFACTURING PROCESSES FOR ENGINEE

- A plate that is 260 mm wide and 27 mm thick is to be reduced in a single pass in a two‑high rolling mill to a thickness of 22 mm. The roll has a radius = 510 mm, and its speed = 25 m/min. The work material has a strength coefficient = 235 MPa and a strain hardening exponent = 0.21. Determine (a) roll force, (b) roll torque, and (c) power required to accomplish this operationarrow_forwardIn open-die forging, a disc of diameter 200 mm and height 60 mm is compressed without any barreling effect. The final diameter of the disc is 400 mm calculate the true strain.arrow_forwardA strip with cross section 120 X 6 mm is being rolled with 20 % reduction area, using rolls of 400mm diameter the coefficient of friction is 0.1 Determine the final strip thickness the angle of bite, length of deformation zonearrow_forward

- A solid cylindrical work piece is reduced in height by an open die forging process using flat dies on a mechanical press, powered by a 20 kW motor which operates at 35 strokes per minute with a stroke length of 160 mm. The work piece is 60 mm high and 100 mm in diameter and is to be reduced in height by 15%. The coefficient of friction during the operation is 0,18. Calculate the flow stress of work piece material if the press is set to operate at 90% of its maximum capacity.arrow_forwardIn a rolling operation using a roll of diameter 1.5 m, if a 35 mm thick plate cannot be reduced to less than 12 mm in a single pass then calculate the coefficient of friction btween the rolls and the plate.arrow_forwardIn a rolling operation using rolls of diameter 500 mm, if a 25 mm thick plate cannot be reduced to less than 20 mm in one Pass, Estimate the coefficient of friction between the roll and the plate.arrow_forward

- 1. A round wire made from 1020 carbon steel is being drawn from a diameter of 12.5 mm to 9.5 mm in a draw die of 10°. For a coefficient of friction of 0.15, calculate required drawing force. 2. How would the extrusion process be effected if the die angle is increased?arrow_forwardA 42mm thick low carbon steel plate is reduced to 34mm in one rolling pass. At the same time that the thickness is reduced, the plate is widened by 4%. The elastic limit of the steel plate is 174MPa and its resistance is 290MPa. The input speed of the plate is 15m/min. The radius of the cylinder is 52.8mm and the rotation speed is 49 revolutions per minute. Determine: a) The minimum coefficient of friction that will make this rolling operation possible. b) The output speed of the plate c) Slide forwardarrow_forwardIn a sheet metal forming press, the shape to be formed is hemispherical cup of radius 15 cm in 2mm thick mild steel sheet. The force required to deform sheet is 8 kN. The forming hammer should approach job from a distance of 30 cm. The production rate required is 240 components/hr. Calculate and suggest the following specifications of the various hydraulic components used: a. Hydraulic cylinder (bore & length); b. Pump pressure and flow rate; c. Electric motor HP considering 75% pump efficiency; d. Reservoir size; and e. Size of pump inlet and discharge tubing.arrow_forward

- A hard metal ball of 10mm diameter is slid across a soft metal surface and produces a groove of3mm width. The interfacial shear strength is one-tenth of the bulk shear strength of the softermetal. For an experimentally measured coefficient of friction of 0.45 for the contact, calculatethe percentage contribution of adhesive and ploughing components to the total coefficient offriction.arrow_forwardA metal strip is to be rolled from an initial wrought thickness of 3.5 mm to a final rolled thickness of 2.5 mm in a single pass rolling mill having rolls of 250 mm diameter. The strip is 450 mm wide. The average coefficient of friction in the roll gap is 0.08. Taking plane strain low stress of 140 MPa, for the metal and assuming negligible spreading, the roll separating force is.....arrow_forwardA cylindrical working part is subjected to a forging landfall operation. The blank is 3.0 in. high and 2.0 in. diameter. In operation, its height is reduced to 1.5 in. The work material has a yield curve defined by K = 50 ksi and n = 0.17. Assume a coefficient of friction of 0.1. Determine the force at the beginning of the process, at intermediate heights of 2.5 in. and 2.0 in., and at the final height of 1.5 in.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY