Concept explainers

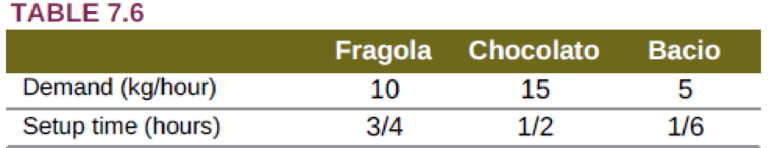

Bruno Fruscalzo decided to set up a small production facility in Sydney to sell to the local restaurants who want to offer gelato on their dessert menu. To start simple, he would offer only three flavors of gelato: fragola (strawberry), chocolato (chocolate), and bacio (chocolate with hazelnut). After a short time, he determined his demand and setup times, listed in Table 7.6.

Bruno first produces a batch of fragola, then a batch of chocolato, then a batch of bacio, and then he repeats that sequence. For example, after producing bacio and before producing fragola, he needs 45 minutes to set up the ice cream machine, but he needs only 10 minutes to switch from chocolato to bacio. When running, his ice cream machine produces at the rate of 50 kgs per hour no matter which flavor it is producing (and, of course, it can produce only one flavor at a time).

- a. Suppose they operate with a production cycle of 150 kgs (50 kg of fragola, 75 kgs of chocolato, and 25 kgs of bacio). What is the capacity of the gelato-making process (in kgs per hr)?

- b. Suppose they operate with a production cycle of 150 kgs (50 kg of fragola, 75 kgs of chocolato, and 25 kgs of bacio). What is the utilization of the gelato-making process?

- c. Suppose they operate with a production cycle of 150 kgs (50 kg of fragola, 75 kgs of chocolato, and 25 kgs of bacio). What is the average inventory of chocolato?

- d. Suppose Bruno wants to minimize the amount of each flavour produced at one time while still satisfying the demand for each of the flavors. (He can choose a different quantity for each flavor.) If we define a batch to be the quantity produced in a single run of each flavor, how many kgs should he produce in each batch?

- e. Given your answer to part (d), how many kgs of fragola should he make with each batch?

Want to see the full answer?

Check out a sample textbook solution

Chapter 7 Solutions

Operations Management

Additional Business Textbook Solutions

Operations Management: Processes and Supply Chains (12th Edition) (What's New in Operations Management)

Operations Management: Processes and Supply Chains (11th Edition)

Principles of Operations Management: Sustainability and Supply Chain Management (10th Edition)

Operations Management

Business in Action (8th Edition)

Principles Of Operations Management

- 1 Demand planning is an activity to determine what quantity of materials and resources have to be procured and when.Select one:a. Trueb. Falsearrow_forwardThe following production data were taken from the records of the finishing department for June: Inventory in process, June 1, 25% completed 260 units Transferred to finished goods during June 5,000 units Equivalent units of production during June 5,495 units Determine the number of equivalent units of production in the June 30, finishing department inventory, assuming that the first-in, first-out method is used to cost inventories. The completion percentage of 25% applies to both direct materials and conversion costs. a.448 units b.840 units c.672 units d.560 unitsarrow_forward1. A company that produces golf carts has just received an order for 200 carts, which must be ready for delivery at the start of week 8. Information concerning the product structure, lead times and quantities on hand is shown in the following table. Parts list for golf cart Lead time Quantity on hand Golf cart Top Base 1 1 1 0 40 20 Top Supports(4) Cover 1 1 200 0 Base Motor Body Seats (2) 2 3 2 300 50 120 Body Frame Controls Wheel assemblies(4) 1 1 1 35 0 240 You are required to: a) Construct a product tree.arrow_forward

- 1. A company that produces golf carts has just received an order for 200 carts, which must be ready for delivery at the start of week 8. Information concerning the product structure, lead times and quantities on hand is shown in the following table. Parts list for golf cart Lead time Quantity on hand Golf cart Top Base 1 1 1 0 40 20 Top Supports(4) Cover 1 1 200 0 Base Motor Body Seats (2) 2 3 2 300 50 120 Body Frame Controls Wheel assemblies(4) 1 1 1 35 0 240 You are required to: a) Construct a product tree. b) Determine the low level codes for all the components. c) Develop a material requirements plan that will provide 200 golf carts by week 8 assuming lot for lot ordering.arrow_forwardHeather Adams, production manager for a Colorado exercise equipment manufacturer, needs to schedule an order for 50 UltimaSteppers, which are to be shipped in week 9. Subscripts indicate quantity required for each parent. Assumelot-for-lot ordering. c) Develop a net material requirements plan for F (enter your responses as whole numbers). Week Lead Time Item 2 3 4 5 6 7 8 9 (weeks) F Gross req Insert answer insert answer 2 On hand insert answer insert answer Net req insert answer insert answer Order receipt insert answer insert answer Order release insert answer insert answerarrow_forward10. Define the following terms: - Fill or Kill Order: - Priority Rule: - Public Order Rule:arrow_forward

- A phone production company must prepare the production planning for the next 9 weeks. Complete the below table considering this information: Lead Time = 3 Weeks On-hand inventory of 52 phones from week 1. Receipt from an outside supplier of 15 phones at start of week 7 We need to supply 75 phones on week 4. We need to supply 120 phones on week 9. Product A Week 1 2 3 4 5 6 7 8 9 Gross Requirement On-hand inventory Planned orderarrow_forwardBilly B. decided four years ago to add high bush blueberries to his commercial vegetable farm near Whitesville. The first two years he did not harvest any berries. In the third year he had a very small crop but was not able to sell to the public. This year things look very good for the crop and he expects to produce 3000 pints. Billy has done a good job of keeping up with his costs, which include variable cost of $953.54, fixed cost of $863.92, and labor cost of $600. He believes the best method of marketing his crop is on a pick your own basis. Billy would like some help in determining what he should charge per pint for his berries. Answer the questions below to give Billy some direction on determining an asking price. 1. 2. 3. 4. 5. What factors should Billy consider in determining the price? What is the minimum price Billy can charge and break even on his crop? What price should he charge and why? What other methods can be used to determine price? If there is competition how will…arrow_forwardA partially completed inventory record for the motor sub-assembly is shown in Figure 11.39.a. Complete the last three rows of the record by using theL4L rule.b. Complete the last three rows of the record by using thePOQ rule with P = 2. c. Complete the last three rows of the record by using thePOQ rule with P = 2.d. If it costs the company $1 to hold a unit in inventory fromone week to the next, and the cost to release an order is$50, which of the lot sizing rules used above will providethe lowest inventory holding + order release cost?arrow_forward

- 3) Amelia Ltd. makes a plastic tricycle that is composed of three major components: a handlebar-front wheel-pedal assembly, a seat and frame unit, and rear wheels. The company has orders for 48,000 of these trikes. Current schedules yield the following information. Requirements Cost to Cost to Component Plastic Time Space Manufacture Purchase Front 12 40 8 16 24 Seat/Frame 16 24 8 12 18 Rear wheel (each) .20 8 .4 2 6 Available 100000 320000 60000 The company obviously does not have the resources available to manufacture everything needed for the completion of 24000 tricycles so has gathered purchase information for each component. Develop a linear programming model to tell the company how many of each component should be manufactured and how many should be purchased in order to provide 24000 fully completed tricycles at the minimum cost.arrow_forwardQuestion 4 If Standard output is 140 units, X has completed 110 units, Y has completed: 125 units, Z has completed: 165 units, standard rate is 30 taka/unit then what would be their wage based on Taylor and Merrick’s plan? Identify similarities and dissimilarities of the above-mentioned plan.arrow_forwardWeek 4 6 7 Gross req. 60 20 150 Item# What is needed# Quantity needed A B 1 A C 2 B C 1 Item# On hand (beginning) inventory# Lot sizing# Lead time A 35 L4L 1 B 65 30 1 C 110 L4L 1 The three tables above shows the master production schedule and the bill of materials of part A, and the inventory records of all the parts. There are no scheduled receipts. Given this information, what is the planned order receipt of part C in Week 6?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,