Concept explainers

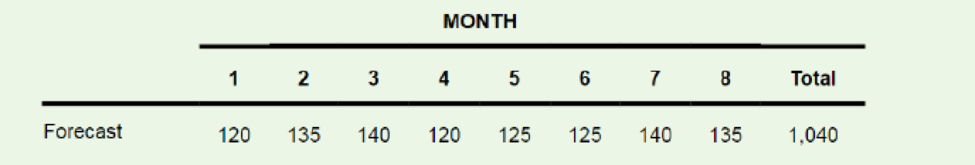

Manager T. C. Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregate plan given the

a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Regular production can be less than regular capacity.

b. Compare the costs to a level plan that uses inventory to absorb fluctuations. Inventory carrying cost is $2 per engine per month. Backlog cost is $90 per engine per month. There should not be a backlog in the last month.

Want to see the full answer?

Check out a sample textbook solution

Chapter 11 Solutions

OPERATIONS MANAGEMENT W/ CNCT+

Additional Business Textbook Solutions

Operations Management: Sustainability and Supply Chain Management (12th Edition)

Operations Management: Processes and Supply Chains (12th Edition) (What's New in Operations Management)

Operations and Supply Chain Management 9th edition

Operations Management: Processes and Supply Chains (11th Edition)

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

Principles Of Operations Management

- Scenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. Ethical decisions that affect a buyers ethical perspective usually involve the organizational environment, cultural environment, personal environment, and industry environment. Analyze this scenario using these four variables.arrow_forwardScenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. What should Sharon do in this situation?arrow_forwardScenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. What does the Institute of Supply Management code of ethics say about financial conflicts of interest?arrow_forward

- Deb Bishop Health and Beauty Products has developeda new shampoo, and you need to develop its aggregate schedule.The cost accounting department bas supplied you the costsrelevant to the aggregate plan, and the marketing department hasprovided a four-quarter forecast. All are shown as follows: Your job is to develop an aggregate plan for the next four quarters.a) First, try hiring and layoffs (to meet the forecast) as necessary.b) Then try a plan that holds employment steady.c) Which is the more economical plan for Deb Bishop Healthand Beauty Products?arrow_forwardA manager is attempting to put together an aggregate production plan for the coming nine months. She has obtained forecasts of aggregate demand for the planning horizon. The plan must deal with highly seasonal demand; demand is relatively high in months 3 and 4, and again in month 8, as can be seen below: The company has 20 permanent employees, each of whom can produce 10 units of output per month at a cost of $6 per unit. Inventory holding cost is $5 per unit per month, and back-order cost is $10 per unit per month. The manager is considering a plan that would involve hiring two people to start working in month 1, one on a temporary basis who would work until the end of month 5. The hiring of these two would cost $500. Beginning inventory is 0.Start with 20 permanent workers. Prepare a minimum cost plan that may use some combination of hiring ($250 per worker), subcontracting ($8 per unit, maximum of 20 units per month, must use for at least three consecutive months), and overtime…arrow_forwardDevelop a chase aggregate plan for Draper using apermanent workforce of 12 employees supplemented by overtime.All demand must be met each period.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.arrow_forward

- The swim department sales for summer are being planned up by 3.2%. Last year's actual sales were $3,880,000. What is the sales dollar plan for swim for this year?arrow_forwardNowJuice, Inc. produces bottled pickle juice. A planner has developed an aggregate forecast for demand (in cases) for the next four months. Use the following information to develop an aggregate plan using the LEVEL strategy. Inventory holding cost is $1 per month per case and backlog cost is $5 per month per case. Beginning inventory is zero. Month May June July August Forecast 452 520 600 719 Cost Per Unit Monthly Capacity Regular Production 19.40 400 Overtime Production 1.5 x Regular Prod Cost 400 What is the TOTAL cost of the LEVEL plan over the planning horizon? Correct Answer 51,588.6 CAN SOMEONE SHOW ME HOW THEY GOT THE ANSWER 51588.6arrow_forwardSales for Pandora’s Jewellery for the past three months have been 200,350, and 287. Usea three-month moving average to calculate a forecast for the fourth month. If the actual demandfor month 4 turns out to be 300, calculate the forecast for month 5.arrow_forward

- How does the Wilson approach handle demand forecasting and inventory planning for new product launches?arrow_forwardDeb Bishop Health and Beauty Products has developed a new shampoo and you need to develop its aggregate schedule. The cost accounting department has supplied you the cost relevant to the aggregate plan and the marketing department has provided a four-quarter forecast. the four-quarter forecast. Quarter Forecast 1 1,400 2 1,100 3 1,700 4 1,300 the costs relevant to the aggregate plan. Costs Previous quarter's output 1,600 units Beginning inventory 0 units Stockout cost for backorders $55 per unit Inventory holding cost $11 per unit for every unit held at the end of the quarter Hiring workers $50 per unit Layoff workers $75 per unit Unit cost $35 per unit Overtime $20 extra per unit Subcontracting Not available Your job is to develop an aggregate plan for the next four quarters. Part 2 a) Try hiring and layoffs (to meet the forecast) as necessary…arrow_forwardDevelop a level aggregate plan for the Draper Tax Companyif back orders are permitted.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.arrow_forward

- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning