Concept explainers

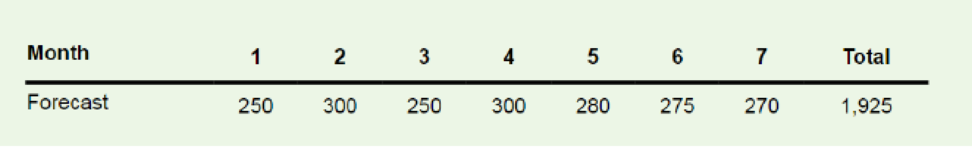

Manager Chris Channing of Fabric Mills, Inc., has developed the

a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. Regular production can be less than regular capacity.

b. Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above regular capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The inventory carrying cost is $2 per hundred bolts.

Want to see the full answer?

Check out a sample textbook solution

Chapter 11 Solutions

OPERATIONS MANAGEMENT W/ CNCT+

- Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. Is Ben Gibson acting legally? Is he acting ethically? Why or why not?arrow_forwardScenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. As the Marketing Manager for Southeastern Corrugated, what would you do upon receiving the request for quotation from Coastal Products?arrow_forwardScenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. Ethical decisions that affect a buyers ethical perspective usually involve the organizational environment, cultural environment, personal environment, and industry environment. Analyze this scenario using these four variables.arrow_forward

- Scenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. What should Sharon do in this situation?arrow_forwardScenario 4 Sharon Gillespie, a new buyer at Visionex, Inc., was reviewing quotations for a tooling contract submitted by four suppliers. She was evaluating the quotes based on price, target quality levels, and delivery lead time promises. As she was working, her manager, Dave Cox, entered her office. He asked how everything was progressing and if she needed any help. She mentioned she was reviewing quotations from suppliers for a tooling contract. Dave asked who the interested suppliers were and if she had made a decision. Sharon indicated that one supplier, Apex, appeared to fit exactly the requirements Visionex had specified in the proposal. Dave told her to keep up the good work. Later that day Dave again visited Sharons office. He stated that he had done some research on the suppliers and felt that another supplier, Micron, appeared to have the best track record with Visionex. He pointed out that Sharons first choice was a new supplier to Visionex and there was some risk involved with that choice. Dave indicated that it would please him greatly if she selected Micron for the contract. The next day Sharon was having lunch with another buyer, Mark Smith. She mentioned the conversation with Dave and said she honestly felt that Apex was the best choice. When Mark asked Sharon who Dave preferred, she answered, Micron. At that point Mark rolled his eyes and shook his head. Sharon asked what the body language was all about. Mark replied, Look, I know youre new but you should know this. I heard last week that Daves brother-in-law is a new part owner of Micron. I was wondering how soon it would be before he started steering business to that company. He is not the straightest character. Sharon was shocked. After a few moments, she announced that her original choice was still the best selection. At that point Mark reminded Sharon that she was replacing a terminated buyer who did not go along with one of Daves previous preferred suppliers. What does the Institute of Supply Management code of ethics say about financial conflicts of interest?arrow_forwardGiven the following forecast and steady regular output of 550 every month, what total cost would result if overtime is limited to a maximum of 40 units a month, and subcontracting is limited to a maximum of 10 units a month? Unit costs are: Regular output $20 Overtime $30 Subcontract $25 Average Inventory $10 Backlog $18 Month 1 2 3 4 5 6 Forecast 540 540 570 590 650 680arrow_forward

- The Bango Toy Company produces several types of toys to seasonal demand. The forecast for the next six months in thousands of dollarsis given below:July Aug. Sept. Oct. Nov. Dec.Forecast $1000 $1500 $2000 $1800 $1500 $1000A regular employee can produce $10,000 worth of toys per month, and the company has 80 regular employees excel at the end of June. Regular-time employees are paid $3800 per month, including benefits. An employee on overtime produces at the same rate as on regular time but is paid at 150 percent of the regular pay. Up to 20 percent overtime can be used in any one month. A worker can be hired for $1000, and it costs $2000 to lay off an employee. Inventory carrying costs are 30 percentper year. The company wishes to end the year with 80 employees. Beginning inventory of toys is $900,000.a. Calculate the cost of a chase strategy.b. Calculate the cost of a level strategy.c. Using the Excel template, simulate several other strategies.d. Determine the effect on the chase…arrow_forwardEight Glasses A Day: The EGAD Bottling Company has decided to introduce a new line of premium bottled water that will include several designer flavors. Marketing manager Georgianna is predicting an upturn in demand based on the new offerings and the increased public awareness of the health benefits of drinking more water. She has prepared aggregate forecasts for the next six months, as shown, Month May June July Aug Sep Oct Total Forecast 50 60 70 90 80 70 420 Production manager Mark Mercer, has developed the following information. (Note: Costs are in thousands of dollars). Regular production cost: $1 per tankload Regular production capacity: 60 tankloads Overtime production cost: $1.6 per tankload Subcontracting cost: $1.8 per tankload Holding cost: $2 per tankload per month Back ordering cost: $5 per month per tankload Beginning inventory: 0 units Among the strategies being considered are: 1. Level production supplemented by up to 10 tank loads a month from overtime 2. A…arrow_forwardCreate a minimum cost chase plan for the forecast shown in the table. There is no beginning inventory and regular production capacity is 350 units and costs $8 per unit. Overtime costs $19 and is limited to 50 units per month and subcontracting is limited to 100 units per month and costs $14 per unit. What is the total plan cost? Hint: In a chase production plan, production is changed each time period to match the demand. Use regular production, overtime, and subcontracting to create the plan. Month Forecast Regular Overtime Subcontracting January 250 February 400 March 500 April 350arrow_forward

- A store’s demand figures are given in the table. According to this, what is the linear regression forecast for Week 12. (You need to use Excel to solve this problem. Do not round intermediate calculations. Round your final answers to two decimal places.arrow_forwardDemand at Nature Trails Ski Resort has a seasonal pattern.Demand is highest during the winter, as this is the peak ski season.However, there is some ski demand in the spring and even fallmonths. Th e summer months can also be busy as visitors oft encome for summer vacation to go hiking on the mountain trails.Th e owner of Nature Trails would like to make a forecast for eachseason of the next year. Total annual demand has been estimatedat 4000 visitors. Given the last two years of historical data, what isthe forecast for each season of the next year?arrow_forwardGreenfield Equipment is performing demand forecasting. Actual demand for Week 1 – 550, Week 2 – 490, Week 3 – 560, week 4 – 435, and Week 5 – 656. You have been asked to perform exponential smoothing with a delta of 0.3. Week 5 forecast was 519. What is week 6 forecast? Provide answer rounded to 1 decimal place.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning