Concept explainers

Repeat Problem 19-7 using two different depths of untreated aggregate bases of 6 in. and 12 in. Highway contractors in your area can furnish rates for providing and properly laying an asphalt concrete surface and untreated granular base. Assume a structural coefficient of 0.12 for the base course. If these rates are available, determine the cost for constructing the different pavement designs if the highway section is 5 miles long and the lane width is 12 ft. Which design will you select for construction?

The cost for constructing the different pavement designs.

Answer to Problem 13P

Explanation of Solution

Given information:

Following is the given information:

Equivalent single axle load, ESAL =

CBR =

Subgrade resilient modulus =

Sub-base layer coefficient =

Granular base layer coefficient =

Elastic modulus of asphalt concrete =

mi = 1, Percentage of traffic on design lane =

SN = 4, reliability level =

and design serviceability loss =

Calculation:

We have the following formula for the calculation of truck factor:

Where, ESAL i= equivalent accumulated 18,000-lb (80-kN) single-axle load for the axle category i

fd= design lane factor,

G rn= growth factor for a given growth rate r and design period n

AADT i= first-year annual average daily traffic for axle category i

N i= number of axles on each vehicle in category i

F Ei= load equivalency factor for axle category i

Calculate ESAL for passenger car

We have the following formula for the calculation of design serviceability :

Substitute the values in the required equation.

Initial serviceability index,

Terminal serviceability index,

Let's determine the resilient modulus of subgrade:

The resilient modulus of subgrade is 1500 times CBR

The value of resilient modulus is given as follows:

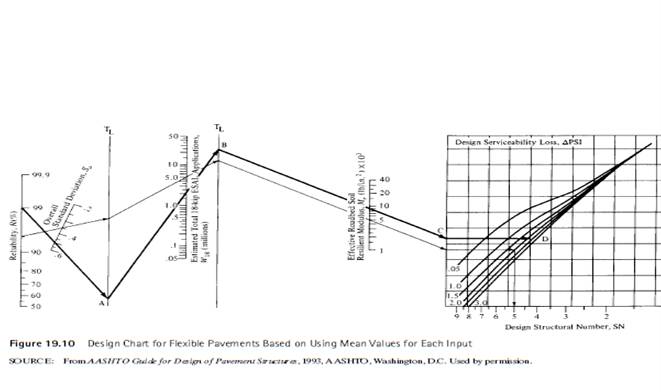

Now for the structural number, SN refer to figure 19.10

The reliability level is 90%. Starting from the point 90% in figure, extend this point to standard deviation 0.45. From standard deviation point, extend this line to line A as given in the figure.

From line A extend this line to

From ESAL extend this line to line B in the figure.

From line B extend this line to

From M rextend this line till it touches the graph. From that point, draw a horizontal line to touch the design serviceability loss, which is 2.

Extend a line vertically and take the structural number SN3reading, which is 2.5 and SN2is 2.3

Then from figure 19.6, for layer coefficient and the resilient modulus for base layer is

From figure 19.10, resilient modulus is

Refer figure 19.7 to determine layer coefficient

Now, considering the thickness aggregate base as 6 inches.

Calculate the minimum thickness.

The layer coefficient,

Substitute the values

Checking the values, we have

As the values match, thus the thickness of subgrade calculated is correct.

Calculate the required minimum thickness of base course D2is 6 inches.

Check whether the calculated thickness agrees with the calculated structural number using equation

Substituting the values, we have

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

Now, the required minimum thickness of the sub-base course

By substituting the values, we have

Now, check if the calculated thickness agrees with the calculated structural number of using the following equation:

Substituting the values

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

The thickness of surface 4.25 inches.

Now, considering the thickness aggregate base as 12 inches.

Calculate the minimum thickness.

Substitute the values, we have

Thus, the thickness of sub grade is 1.7 in.

Now, the thickness of the base course is given as follows:

Substitute the values.

Which is greater than 2.7, i.e., structural number.

Now, the required minimum thickness of the sub-base course

By substituting the values,

Now, check if the calculated thickness agrees with the calculated structural number of using the following equation

Substituting the values,

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

Calculate construction cost for the highway considering thickness of base layer as 6 inches and 12 inches.

The cost is calculated by multiplying the measurement of road with the cost per rate.

Assume cost of surface layer as

For cost of base layer

For cost of sub-base layer

The construction cost of the highway is as follows:

Cost = L X B X t X C

For surface layer :

Substitute the values

5 miles is equal to 26400

For base layer :

Substitute the values

For sub-base layer :

Substitute the values

Now, calculate the total cost as follows:

The construction cost of the highway is as follows:

Cost = L X B X t X C

For surface layer :

Substitute the values

5 miles is equal to 26400

For base layer :

Substitute the values

For sub-base layer :

Substitute the values

Now, calculate the total cost as follows:

Conclusion:

Therefore, out of two cases the construction cost is

Want to see more full solutions like this?

- Subject : Transportation Engineering Read the question carefully and give me right solution according to the question. Note: solve by using 45-deg cone pressure distribution method only The maximum wheel load that the pavement could carry is 120 kN. If the contact radius of the wheel is assumed to be 250 mm, and subgrade bearing capacity is equivalent to 0.24 Megapascals, calculate the subgrade layer thickness of the flexible pavement in mm using the 45-deg cone pressure distribution method.arrow_forwardShow transcribed image text 1. Truck A has two single axles. One axle weighs 12,000 Ib and the other weighs 23,000 lb. Truck B has an 8000-lb single axle and a 43,000-lb tandem axle. On a flexible pavement with a 3-inch hot-mix asphalt (HMA) wearing surface, a 6-inch soil-cement base, and an 8-inch crushed stone sub base, which truck will cause more pavement damage? (Assume drainage coefficient are 1.0.) Hints: use linear interpolation if SN is not integer. 2. A highway has the following pavement design daily traffic: 300 single axles at 10,000 lb each, 120 single axles at 18,000 lb each, 100 single axles at 23,000 Ib each, 100 tandem axles at 32,000 lb each, 30 single axles at 32,000 lb each, and 100 triple axles at 40,000 lb each. A flexible pavement is designed to have 4 inches of sand-mix asphalt wearing surface, 6 inches of soil- cement base, and 7 inches of crushed stone sub base. The pavement has a 10-year design life, a reliability of 85%, an overall standard deviation of 0.30,…arrow_forwardDescribe the fundamental kinds of highway concrete pavements and the circumstances that will be used to create each type.arrow_forward

- Q2: The traffic on the design lane of a proposed four-lane rural interstate highway consists of 40% trucks. If classification studies have shown that the truck factor can be taken as 0.45, design a suitable flexible pavement using the 1993 AASHTO procedure if the AADT on the design lane during the first year of operation is 1150, pi = 4.5, and pt = 2.5 . Growth rate = 3% Design life = 20 years Reliability level = 95% Standard deviation = 0.45 The pavement structure will be exposed to moisture levels approaching saturation 20% of the time, and it will take about one week for drainage of water. Effective CBR of the subgrade material is 7. CBR of the base and subbase are 70 and 22, respectively, and Mr for the asphalt mixture, 3102 MPa (450,000 lb/in2).arrow_forwardA concrete pavement is to be constructed for a four-lane urban expressway on a subgrade with an effective modulus of subgrade reaction k of 100 lb/in3. The accumulated equivalent axle load for the design period is 3.25 x 106. The initial and terminal serviceability indices are 4.5 and 2.5, respectively. Using the AASHTO design method, determine a suitable thickness of the concrete pavement if the working stress of the concrete is 600 lb/in2 and the modulus of elasticity is 5 x 106lb/in2. Take the overall standard deviation So as 0.30, the load-transfer coefficient J as 3.2, the drainage coefficient as 0.9, and R = 95%.arrow_forwardQ#3. Discuss root causes and remedial measures of the following distresses occurring in flexible pavements: Slippage failure, Potholes, Rutting and its types, Bitumen bleedingarrow_forward

- Q:Discuss various tests used for the quality of aggregate used in flexible pavements.arrow_forwardanswer with complete solution. Asap 1. determine the safe thickness of rigid pavement if the wheel load is 85 kN and f'c = 32 MPaarrow_forwardQ=Discuss various tests used for the quality of aggregate used in flexible pavements. Answer in word formatarrow_forward

- In 1996, a rigid pavement on a northbound section of interstate highway was designed with a 12-inch PCC slab, an Ec of 6x10^6 lb/in^2, a concrete modulus of rupture of 800 lb/in^2, a load transfer coefficient of 3.0, an initial PSI of 4.5, and a terminal serviceability index of 2.5. The overall standard deviation was 0.45, the modulus of subgrade reaction was 190 lb/in^3, and a reliability of 95% was used along with a drainage coefficient of 1.0. The pavement was designed for a 10-year life, and traffic was assumed to be composed entirely of tractor semi-trailer trucks with one 16-kip single axle, one 20-kip single axle, and one 35-kip tandem axle (the effect of all other vehicles was ignored). The interstate has four northbound lanes and was conservatively designed. How many tractor semi-trailer trucks, per day, were assumed to be traveling in the northbound direction?arrow_forwardQ, Discuss the following terms briefly: a, Emulsion breaking and Cutback curing, b, Water bound and aggregate base, c, Flexible pavement and Rigid pavements,arrow_forwardHow sensitive are the critical pavement responses to (a) increased tire pressure, (b) increased subgrade strength, (c) Poisson’s ratio changes, (d) lime stabilization of top 6 in. of subgrade, (e) asphalt or cement stabilization of base layer, etcarrow_forward

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning