Concept explainers

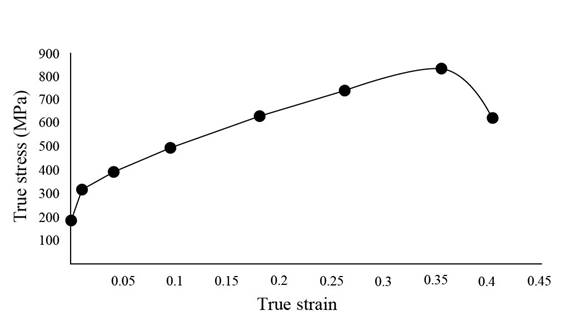

The stress-strain curve.

Explanation of Solution

Given:

The initial area is

The final area is

The original length is

Formula used:

The true strain is given as,

Here,

The Actual area is given as,

The actual are for the initial load is given as,

The final length is given as,

Here,

The stress is given as,

Here, P is the applied load.

Calculation:

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,\

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

For

The final length can be calculated as,

The strain can be calculated as,

The actual area can be calculated as,

The stress can be calculated as,

The stress-strain curve from the above calculation is given as,

Figure 1.1

Want to see more full solutions like this?

Chapter 2 Solutions

Manufacturing Processes for Engineering Materials (6th Edition)

- Draw a typical stress vs strain tensile test curve for the following materials (two seperate graphs) and label the axis. A ductile metallic test specimen that is stretched to failure displaying a characteristic yield point and show the following parts on the curve. 1- Yield point 2- Ultimate Tensile Strength 3- Breaking point 4- Elastic Region 5- Plastic Region 6- Necking regionarrow_forwardA cylindrical specimen of brass that has a diameter of 20 mm, a tensile modulus of 110 GPa, and a Poisson's ratio of 0.35 is pulled in tension with a force of 40, 000 N. If the deformation is totally elastic, what is the strain experienced by the specimen along the longitudinal direction?arrow_forwardDraw a typical stress vs strain tensile test curve for the following material and label the axis. A typical brittle material subjected to a tensile stress that has been applied to the material till the sample breaks. 1- label the axis and draw the curve for a brittle material. 2- indicate the maximum strength of the material. 3- show on the portion of the curve where young's modulus can be calculated.arrow_forward

- A tensile specimen is elongated to twice its original length. Determine the engineering strain and true strain for this test? If the values are different explanations why they are different?arrow_forwardA cylindrical specimen of brass that has a diameter of 15 mm, a tensile modulus of 120 GPa, and a Poisson’s ratio of 0.30 is pulled in tension with force of 50,000 N. If the deformation is totally elastic, what is the approximate strain experienced by the specimen?arrow_forwardA cylindrical specimen of brass that has a diameter of 21 mm, a tensile modulus of 122 GPa, and a Poisson’s ratio of 0.37 is pulled in tension with force of 38704 N. If the deformation is totally elastic, what is the strain experienced by the specimen?arrow_forward

- Write the definitions for engineering stress, true stress,engineering strain, and true strain for loading along a singleaxis.arrow_forwardA) Suppose you need to design a tension test machine capable of testing specimens that have nominal ultimate stresses as high as σu = 100 ksi . How much force must the machine be capable of generating? Assume the testing specimen has the ASTM shape shown. B) If the maximum nominal strain is ϵf = 0.7 just before the test specimen fractures and the test machine operates by moving only one grip, how far must that grip be designed to travel? The total length of the deforming part of the specimen is 3 in .arrow_forwardFor some metal alloy, a true stress 345 MPa (50040 psi) produces a plastic true strain of 0.02. How much will a specimen of this material elongate when a true stress of 418 MPa (60630 psi) is applied if the original length is 500 mm (19.69in) ? Assume a value of 0.22 for the strain- hardening exponent, narrow_forward

- A tensile test is performed on metal specimen and it found that a true plastic strain of 0.02 is produced true stress of 345 MPa is applied. How much will a specimen of this material elongate when a true stress MPa is applied if the original length is 500 mm. Assume that the value of 0.22 for strain hardening exponent.arrow_forwardYour manager asked you to explain the difference between three-point bending test and four-pointbending test by using a standard specimen each one has the following dimensions:1. Force = 30 KN.2. Thickness= 5 cm.3. Width = 10 cm.4. Length = 25 cm.Calculate the stress on each specimen then justify your answer.arrow_forwardDefine normal strain?arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY