Concept explainers

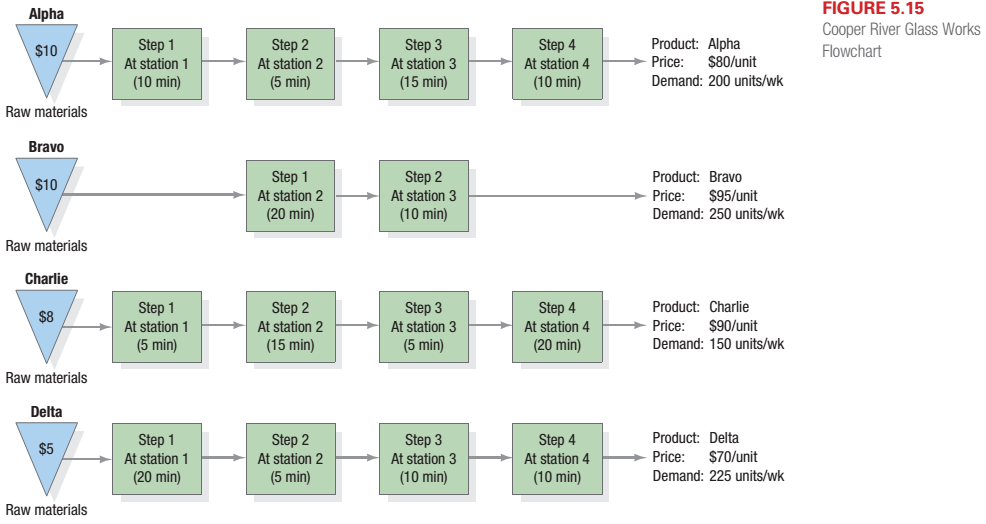

Cooper River Glass Works (RGW) produces four different models of desk lamps as shown in Figure 5.15. The operations manager knows that total monthly demand exceeds the capacity available for production. Thus, she is interested in determining the product mix which will maximize profits. Each model’s price, routing, processing times, and material cost are provided in Figure 5.15. Demand next month is estimated to be 200 units of model Alpha, 250 units of model Bravo, 150 units of model Charlie, and 225 units of model Delta. CRGW operates only one 8-hour shift per day and is

- Which station is the bottleneck?

- Using the traditional method, which bases decisions solely on a product’s contribution to profits and overhead, what is the optimal product mix and what is the overall profitability?

- Using the bottleneck-based method, what is the optimal product mix and what is the overall profitability?

Want to see the full answer?

Check out a sample textbook solution

Chapter 5 Solutions

OPERATIONS MANAGEMENT LL PACKAGE

Additional Business Textbook Solutions

Principles Of Operations Management

Business in Action (8th Edition)

Operations Management: Sustainability and Supply Chain Management (12th Edition)

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

Operations Management

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- Zucchero Sugar, Inc. has six processing departments for refining sugar—Affination, Carbonation, Decolorization, Boiling, Recovery, and Packaging. Conversion costs are added evenly throughout each process. Data from the month of August for the Recovery Department are as follows: Metric Tons Beginning Work−in−Process Inventory 0 Transferred in 22,000 Ending Work−in−Process Inventory 6,000 Costs Beginning Work−in−Process Inventory $0 Costs added during August : Direct materials 530,000 Direct labor 250,000 Manufacturing overhead 105,000 Total costs added during August $885,000 The ending Work−in−Process Inventory is 100% and 95% complete with respect to direct materials and conversion costs, respectively. The weighted−average method is used. How many metric tons of sugar were refined and transferred to the Packaging Department in August? A. 6,000 metric tons B.…arrow_forwardAssuming the following: Warehouse 1 has outbound goods volume - 2,500 units Warehouse 2 has outbound goods volume - 1,300 units Warehouse 3 has outbound goods volume - 5,000 units Given the assumptions and grid coordinates above, the following: d1x= 200, d2x= 300, d3x= 100, d1y= 50, d2y= 100, d3y= 150 And V1= 2,500, V2= 1,300, V3= 5,000 Which is equal to: Cx= (200 x 2,500) + (300 x 1,300) + (100 x 5,000) / (2,500 + 1,300 + 5,000) = 158 Cy= (50 x 2,500) + (100 x 1,300) + (150 x 5,000) / (2,500 + 1,300 + 5,000) = 114 Use the numerical example set up above to demonstrate how the centre of gravity location technique is used.arrow_forwardA manufacturing firm has four plants and wants to find the most efficient means of meeting the requirements of its four customers. The relevant information for the plants and customers, along with shipping costs in dollars per unit, are shown in the table below: Customer (requirement) Factory (capacity) Customer 1 (125) Customer 2 (150) Customer 3 (175) Customer 4 (75) A (100) $ 15 $ 10 $ 20 $ 17 B (75) $ 20 $ 12 $ 19 $ 20 C (100) $ 22 $ 20 $ 25 $ 14 D (250) $ 21 $ 15 $ 28 $ 12 How many supply nodes are present in this problem? Multiple Choice: 4 3 1 8 16arrow_forward

- Polly Astaire makes fine clothing for big and tall men. A fewyears ago Astaire entered the sportswear market with theSunset line of shorts, pants, and shirts. Management wants tomake the amount of each product that will maximize profits.Each type of clothing is routed through two departments, Aand B. The relevant data for each product are as follows: Department A has 120 hours of capacity, department B has160 hours of capacity, and 90 yards of material are available.Each shirt contributes $10 to profits and overhead; each pairof shorts, $10; and each pair of pants, $23.a. Specify the objective function and constraints for thisproblem.b. Use a computer package such as POM for Windows tosolve the problem.c. How much should Astaire be willing to pay for an extrahour of department A capacity? How much for an extrahour of department B capacity? For what range of right-hand values are these shadow prices valid?arrow_forwardACE Company uses a job-costing system at its Marikina plant. The plant has a Machining Department and an Assembly Department. Its job-costing system has two direct-cost catergories direct materials, and direct manufacturing labor) and two manufacturing overhead cost pools (the Machining Department, allocated using actual machine-hours, and the Assembly Department, allocated using actual direct manufacturing labor cost. The 2020 budget for the plant is as follows: Machining Dept. Assembly Dept. Manufacturing Overhead P 1 ,800,000 P 3,600,000 Direct Manufacturing Labor cost 1,400,000 2,000,000 Direct Manufacuring Labor-hours 100,000 200,000 Machine-hours 50,000 200,000 The company uses a budgeted overhead rate for allocating overhead to production orders on a machine-hour basis n Machining and on a direct…arrow_forwardSunseel Industries produces two types of raw materials, A and B, with a production cost of $4 and $8 per unit, respectively. The combined production of A and B must be at least 700 units per month. The factory is expected to produce at least 400 units of B and not more than 1200 units of A each month. The processing times for A and B are observed to be 5 hours and 4 hours, respectively. A total of 3000 production hours are available per month. Develop a linear program that Sunseel Industries can use to determine the number of units of each raw material to produce that will meet the demand and minimize the total cost.arrow_forward

- Hawkins Manufacturing Company produces connecting rods for 4- and 6-cylinder automobile engines using the same production line. The cost required to set up the production line to produce the 4-cylinder connecting rod is $2,000, and the cost required to set up the production for the 6-cylinder connecting rod is $3,500. Manufacturing costs are $15 for each 4-cylinder connecting rod and $18 for each 6-cylinder connecting rod. Hawkins makes a decision at the end of each week as to which product will be manufactured the following week. If a production changeover is necessary from one week to the next, the weekend is used to reconfigure the production line.Once the line has been set up, the weekly production capacities are 6,000 6-cylinder connecting rods and 8,000 4-cylinder connecting rods. Letx4 = the number of 4-cylinder connecting rods produced next week,x6 = the number of 6-cylinder connecting rods produced next week,s4 = 1 if the production line is set up to produce the 4-cylinder…arrow_forward. David’s Sport Supplies is a store that sells sports equipmentand gear for teenagers and young adults. David’s is in the processof assigning the location of storage areas in its warehouse (Figure10-16) to minimize the number of trips made to retrieve neededitems. Given here in Table 10-14 are the departments that needto be located, the number of trips made per week for eachdepartment, and the area needed by each department.arrow_forwardAli is a student in XYZ university. All wants to apportion his available time of about 600 min. a day between work and play. He estimates that play is twice as much fun as work. He also wants to study at least as much as he plays. However, Ali realizes that if he is going to get all his homework assignments done, he cannot play more than 4 hours a day. How should Ali allocate his time to maximize his pleasure from both work and play? a. Formulate a linear programming model for this problem. b. Solve this model by using graphical analysis.arrow_forward

- Please answer the following in an organized way and showing steps. Maxwell Manufacturing makes two models of felt tip marking pens. Requirements and available resources for each lot of pens are given in the following table: Fliptop Model Tiptop Model Available Plastic 3 4 36 Ink Assembly 5 4 40 Molding Time 5 2 30 The profit for either model is $1,000 per lot. a. What is the linear programming model for this problem? b. Using Microsoft Excel's Solver, find the optimal solution. How many Fliptop models and how many Tiptop models should be produced? What is the maximum profit? c. Will there be excess capacity in any resource? Use Excel's Solver and run a sensitivity report to answer the following questions: d. Over which range can the objective function coefficient for Fliptop Models change without affecting the original optimal solution? What is this range called? e. What is the shadow price (dual price) for the plastic constraint and how…arrow_forwardBob Carlton's golf camp estimates the following workforce requirements for its services over the next two years: Quarter 1 2 3 4 5 6 7 8 Demand (hrs) 4,300 6,400 3,200 5,000 4,500 6,300 3,600 5,000 Each certified instructor puts in 480 hours per quarter regular time and can work an additional 120 hours overtime. Regular-time wages and benefits cost Carlton $7,200 per employee per quarter for regular time worked up to 480 hours, with an overtime cost of $20 per hour. Unused regular time for certified instructors is paid at $15 per hour. There is no cost for unused overtime capacity. The cost of hiring, training, and certifying a new employee is $10,000. Layoff costs are $4,000 per employee. Currently 8 employees work in this capacity. a. Find a workforce plan using the level strategy that allows for no delay in service. It should rely only on overtime and the minimum amount of undertime necessary. What is the total cost of the…arrow_forwardBob Carlton's golf camp estimates the following workforce requirements for its services over the next two years: Quarter 1 2 3 4 5 6 7 8 Demand (hrs) 4,300 6,400 3,200 5,000 4,500 6,300 3,600 5,000 Each certified instructor puts in 480 hours per quarter regular time and can work an additional 120 hours overtime. Regular-time wages and benefits cost Carlton $7,200 per employee per quarter for regular time worked up to 480 hours, with an overtime cost of $20 per hour. Unused regular time for certified instructors is paid at $15 per hour. There is no cost for unused overtime capacity. The cost of hiring, training, and certifying a new employee is $10,000. Layoff costs are $4,000 per employee. Currently 8 employees work in this capacity. a. Find a workforce plan using the level strategy that allows for no delay in service. It should rely only on overtime and the minimum amount of undertime necessary. What is the total cost of the…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.