OPERATIONS MANAGEMENT LL PACKAGE

11th Edition

ISBN: 9781323592632

Author: KRAJEWSKI

Publisher: Pearson Custom Publishing

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 5, Problem 14P

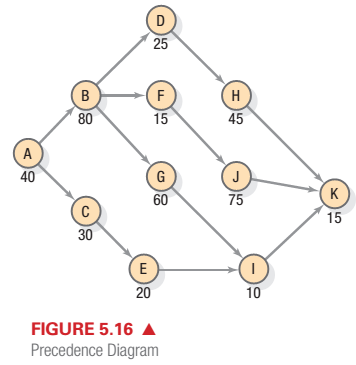

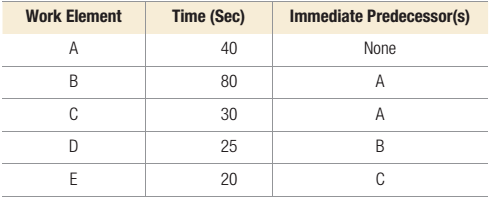

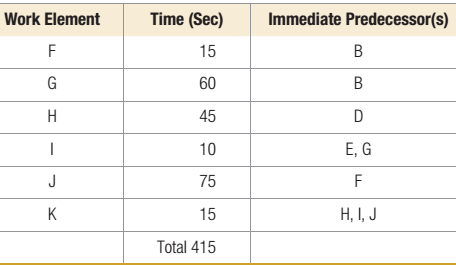

Use the longest work element rule to balance the assembly line described in the following table and Figure 5.16 so that it will produce 40 units per hour.

- What is the cycle time?

- What is the theoretical minimum number of workstations?

- Which work elements are assigned to each workstation?

- What are the resulting efficiency and balance delay percentages?

- Use the shortest work element rule to balance the assembly line. Do you note any changes in solution?

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

The desired daily output for an assembly line is 360 units. This assembly line will operate 450 minutes per day. The following table contains information on this product’s task times and precedence relationships:

TASK

TASK TIME (SECONDS)

IMMEDIATE PREDECESSOR

A

30

—

B

35

A

C

30

A

D

35

B

E

15

C

F

65

C

G

40

E, F

H

25

D, G

What is the required workstation cycle time to meet the desired output rate?

Balance this line using the largest number of following tasks. Use the longest task time as a secondary criterion.

Note: Leave no cells blank - be certain to enter "0" wherever required.

Francis Johnson’s plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only four workstations. The tasks and the order in which they must be performed are shown in the following table. Tasks cannot be split, and it would be too expensive to duplicate any task.

TASK

TASK TIME (MINUTES)

IMMEDIATE PREDECESSOR

A

1

—

B

2

—

C

3

—

D

1

A, B, C

E

3

C

F

2

E

G

3

E

What is the workstation cycle time required to produce 15 units per hour?

Note: Round your answer to 1 decimal place.

Balance the line to use the fewest possible workstations to meet the cycle time found in part (b). Use whatever method you feel is appropriate. What is the efficiency of your line balance, assuming the line operates at the cycle time from part (b)?

Note: Round your answer to 1 decimal place.

The desired daily output for an assembly line is 540 units. This assembly line will operate 720 minutes per day. The following table contains information on this product's task times and precedence relationships:

TASK

TASK TIME(SECONDS)

IMMEDIATEPREDECESSOR

A

35

—

B

25

A

C

35

A

D

55

B

E

5

B

F

15

C

G

30

E-D

H

5

F-G

b. What is the workstation cycle time?

c. Balance this line using the largest number of following tasks. Use the longest task time as a secondary criterion. (Leave no cells blank - be certain to enter "0" wherever required.)

Chapter 5 Solutions

OPERATIONS MANAGEMENT LL PACKAGE

Ch. 5 - Take a process that you encounter on a daily...Ch. 5 - Prob. 2DQCh. 5 - How could the efficiency of the redesigned process...Ch. 5 - Bill’s Barbershop has two barbers available to...Ch. 5 - Melissa’s Photo Studio offers both individual...Ch. 5 - Figure 5.11 details the process flow for two types...Ch. 5 - Prob. 4PCh. 5 - Super Fun Industries manufactures four top-selling...Ch. 5 - Prob. 6PCh. 5 - Yost-Perry Industries (YPI) manufactures a mix of...

Ch. 5 - Prob. 8PCh. 5 - Prob. 9PCh. 5 - A.J.’s Wildlife Emporium manufactures two unique...Ch. 5 - Cooper River Glass Works (RGW) produces four...Ch. 5 - Quick Stop Pharmacy is a small family-owned,...Ch. 5 - Use the longest work element rule to balance the...Ch. 5 - Johnson Cogs wants to set up a line to serve 60...Ch. 5 - Refer back to Problem 16. Suppose that in addition...Ch. 5 - To meet holiday demand, Penny’s Pie Shop...Ch. 5 - A paced assembly line has been devised to...Ch. 5 - Prob. 20PCh. 5 - Greg Davis, a business major at the University of...Ch. 5 - Prob. 1VCCh. 5 - Which boarding scenario among the different ones...Ch. 5 - How should Southwest evaluate the gate boarding...Ch. 5 - How will Southwest know that the bottleneck had...

Additional Business Textbook Solutions

Find more solutions based on key concepts

2. In what circumstances might a market-pull approach or a technology-push approach to new-product design be th...

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

There is a huge demand in the United States and elsewhere for affordable women’s clothing. Low-cost clothing re...

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

What is precedent, and how does it affect common law?

Business in Action

What are the three major business functions, and how are they related to one another? Give specific examples.

Operations Management, Binder Ready Version: An Integrated Approach

2. Identify four people who have contributed to the theory and techniques of operations management.

Operations Management

Many companies including Company OM tried to implement dynamic pricing in their ticketing system. The dynamic p...

Principles of Operations Management: Sustainability and Supply Chain Management (10th Edition)

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- An assembly line is to operate eight hours per day with a desired output of 240 units perday. The following table contains information on this product’s task times and precedencerelationships: Task Task Time (Seconds) Immediate Predecessor A 60 — B 80 A C 20 A D 50 A E 90…arrow_forwardAssembly Line Problem A shop works a 400-minute day. The manager of the shop wants an output of 200 units per day for the assembly line that has the elemental tasks shown in the following table. Task Immediate Predecessor Task(s) Task Time (minutes) a --- 0.5 b a 1.4 c a 1.2 d a 0.7 e b,c 0.5 f d g e 0.4 h g 0.3 i F 0.5 j e, I 0.8 k h, j 0.9 l k 0.3 d)Compute the efficiency of the assembly linearrow_forwardA company needs to rebalance a product layout for producing new plastic license plates. They plan to use the assembly line six hours in order to meet projected demand of 2,160 license plates each day. The following table describes the tasks involved in the production of this product: Without regard to projected demand, what is the maximum possible cycle time for this assembly line? Task Time (secs) Immediate Predecessor a 3 none b 4 none c 5 a,b d 7 none e 9 c,darrow_forward

- About the product v process layouts, which statement(s) is correct?1. Process layout is more flexible, and therefore, it is only applicable to a service context. 2. Compared to a product layout, a process layout is located closer to "Project" in a product-process matrix. 3. Product layout is more efficient, and therefore, it is only applicable to a manufacturing context. 4. Compared to a process layout, a product layout is closer to a fixed-position layout in a product-process matrix. 5. None of the statements are correct Note: You need to provide which statements are correct. It can be more than one.arrow_forwardDynaMore is a video console manufacturer. Information about the company’s two products follows: The company incurs $885,800 in overhead per year and has traditionally applied overhead on the basis of direct labor hours. Each unit of product requires one testing. Required How much overhead will be allocated to each product using the traditional direct labor hours allocation base? What overhead cost per unit will be allocated to each product? Assume that DynaMore has identified three activity cost pools. Given these activity pools and cost drivers, determine the activity rates. How much overhead should be allocated to each TD-1000 under activity-based costing? Explain the difference in overhead costs per console under traditional costing and activity-based costing.arrow_forwardSue Helms Appliances wants to establish an assembly line to manufacture its new product, the Micro Popcorn Popper. The goal is to produce five poppers per hour. The tasks, task times, and immediate predecessors for producing one Micro Popcorn Popper are as follows: a) What is the theoretical minimum for the smallest number of workstations that Helms can achieve in this assembly line?b) Graph the assembly line, and assign workers to workstations. Can you assign them with the theoretical minimum?c) What is the efficiency of your assignment?arrow_forward

- As the Operations Manager of Shane Manufacturing Ltd., you are given the task to balance the assembly line that is used to produce a special type of toy. a. Develop your own scenario (quantitative example) of this line balancing problem. Include all relevant information b. Draw the precedence diagram for the problem that you set up in part “a” above. c. Use the example that you set up to demonstrate how you will balance the line.arrow_forwardThe desired daily ouput for an assembly line is 420 units. This assembly line will operate 595 minutes per day. The following table contains information on the products task times and precedence relationships Task. Task time-seconds Immediate predecessor A. 35 - B. 40 A C 30 A D 40 B E 20 C F 70 C G 45 E-F H 30 D-G The required workstation cycle time to meet the desired output time is 85 seconds Balance this line using the largest number of following tasks. Use the longest task time as a secondary criterion The answer gives only 4 workstations as option Have to fill out following Workstation. Task Idle time 1 ?? ?? 2 ?? ?? 3…arrow_forwardAn assembly line is to operate eight hours per day with a desired output of 200 units per day. The following table contains information on this product’s task times and precedence relationships: TASK TASK TIME(SECONDS) IMMEDIATEPREDECESSOR A 60 — B 60 A C 50 A D 70 A E 30 B, C F 110 C, D G 70 E, F H 70 G b. What is the required workstation cycle time to meet the desired output rate? (Round your answer to the nearest whole number.) c. Balance this line using the longest task time. (Leave no cells blank - be certain to enter "0" wherever required.) d. What is the efficiency of your line balance, assuming it is running at the cycle time determined in part b? (Round your answer to 1 decimal place.)arrow_forward

- An assembly line is to operate eight hours per day with a desired output of 250 units per day. The following table contains information on this product’s task times and precedence relationships: TASK TASK TIME (SECONDS) IMMEDIATE PREDECESSOR A 50 — B 20 A C 25 A D 35 A E 60 B, C F 60 C, D G 50 E, F H 90 G What is the required workstation cycle time to meet the desired output rate? Note: Round your answer to the nearest whole number. Balance this line using the longest task time. Note: Leave no cells blank - be certain to enter "0" wherever required. What is the efficiency of your line balance, assuming it is running at the cycle time determined in part b? Note: Round your answer to 1 decimal place.arrow_forwardThe maker of the world-famous Chocolate Chip Cookies needs to design a product layout for a new product, Mint Chocolate Chip. The company plans to use this new production line eight hours a day in order to meet projected demand of 1,440 cases per day. The following table describes the tasks involved in the production of a case of Mint Chocolate Chip Cookies. 27 seconds 0.3333 seconds 18 seconds 14 seconds 56 seconds 20 secondsarrow_forwardSue Helms Appliances wants to establish an assembly line to manufacture its new product, the Micro Popcorn Popper. The goal is to produce five poppers per hour. The tasks, task times, and immediate predecessors for producing one Micro Popcorn Popper are as follows: Task Performance Time (mins) Task Must Follow Task Listed Below A 8 − B 11 A C 10 A, B D 9 B, C E 8 C F 4 D, E A C F B E D In the diagram, there are 6 circles labeled using the letters from A to F. There are 8 of arrows, and each arrow connects one circle to another circle. The arrows are situated in the following manner: A to B, A to C, B to C, C to D, B to D, C to E, D to F, and E to F. Part 2 a) The theoretical minimum number of workstations=55 (round your response up to the…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY