5-39* to 5-55* For the problem specified in the table, build upon the results of the original problem to determine the minimum factor of safety for yielding. Use both the maximum-shear-stress theory and the distortion-energy theory, and compare the results. The material is 1018 CD steel.

| Problem Number | Original Problem, Page Number |

| 5-41* | 3-70, 151 |

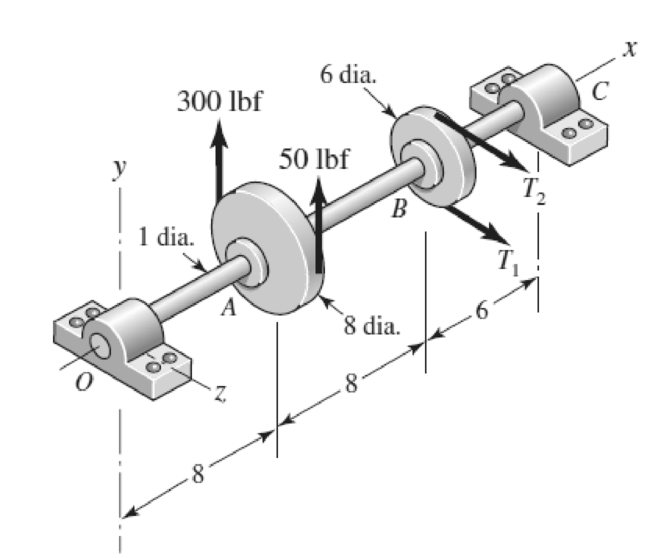

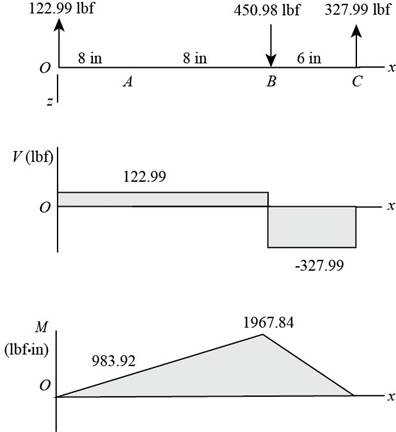

3-68* to 3-71* A countershaft two V-belt pulleys is shown in the figure. Pulley A receives power from a motor through a belt with the belt tensions shown. The power is transmitted through the shaft and delivered to the belt on pulley B. Assume the belt tension on the loose side at B is 15 percent of the tension on the tight side.

- (a) Determine the tensions in the belt on pulley B, assuming the shaft is running at a constant speed.

- (b) Find the magnitudes of the bearing reaction forces, assuming the bearings act as simple supports.

- (c) Draw shear-force and bending-moment diagrams for the shaft. If needed, make one set for the horizontal plane and another set for the vertical plane.

- (d) At the point of maximum bending moment, determine the bending stress and the torsional shear stress.

- (e) At the point of maximum bending moment, determine the principal stresses and the maximum shear stress.

Problem 3-70*

Dimensions in inches.

The factor of safety for yielding from maximum-shear-stress theory.

The factor of safety for yielding from distortion-energy theory.

Answer to Problem 41P

The factor of safety for yielding from maximum-shear-stress theory is

The factor of safety for yielding from distortion-energy theory is

Explanation of Solution

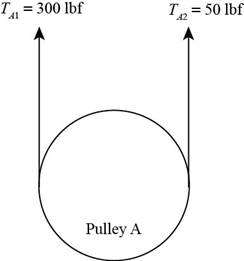

The Free body diagram of pulley

Figure (1)

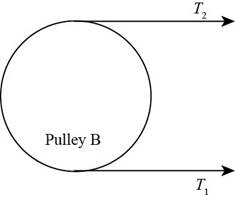

The free body diagram of pulley

Figure (2)

The tension loose side is

It is given that the belt tension on the loose side at

Write the relationship between tension on the loose side with respect to tension on the tight side.

Here, the tension on the tight side is

Write the equation to balance the tension on the counter shaft.

Here, the tension on the tight side of pulley

Substitute

Calculate the tension on the loose side.

Write the magnitude of bearing reaction force at

Here, the magnitude of the bearing force at

Write the magnitude of bearing reaction force at

Write the magnitude of bearing reaction force at

Here, the magnitude of bearing force at

Write the magnitude of bearing force at

Here, the magnitude of bearing reaction force at

Calculate the bearing reaction force at

Here, the bearing reaction force at

Calculate the bearing reaction force at

Here, the bearing reaction force at

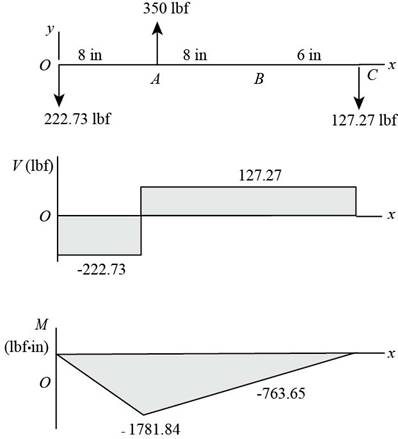

The calculations for shear force and bending moment diagram in

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the moment at

The moment at the supports of the simply supported beam is zero.

Calculate the moment at

Here, the moment at

Calculate the moment at

Here, the moment at

The calculations for shear force and bending moment diagram in

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the moment at

The moment at the supports of the simply supported beam is zero.

Calculate the moment at

Here, the moment at

Calculate the moment at

Write the net moment at

Here, the net moment at

Write the net moment at

Here, the net moment at

Write the torque transmitted by shaft from

Here, the torque transmitted by shaft from

Calculate the bending stress.

Here, the bending stress is

Calculate the shear stress.

Here, the shear stress is

Calculate the maximum principal stress.

Here, the maximum principal stress is

Calculate the minimum principal stress.

Here, the minimum principal stress is

Calculate the maximum shear stress.

Here, maximum shear stress is

Calculate the factor of safety from maximum-shear-stress theory.

Here, the maximum yield stress for

Calculate the factor of safety from distortion-energy theory.

Here, the Von Mises stress is

Write the expression for von Mises stress.

Substitute

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Thus, the shear force diagram and bending moment diagram for the shaft in

Figure (4)

Substitute

Substitute

Substitute

Substitute

Substitute

Thus, the shear force diagram and bending moment diagram for the shaft in

Figure (5)

Substitute

Substitute

Since,

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Refer to the Table A-20 “Deterministic ASTM Minimum Tensile and Yield Strengths for Some Hot-Rolled (HR) and Cold-Drawn (CD) Steels” and obtain

Substitute

Thus, the factor of safety for yielding from maximum-shear-stress theory is

Substitute

Thus, the factor of safety for yielding from distortion-energy theory is

Want to see more full solutions like this?

Chapter 5 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- An input shaft of a gearbox with motor power P = 7 kW and rotation number n = 1300 rpm. The diameter of an input shaft is d = 20 mm and its material is 16MnCr5. A force of F = 2800 N forces the shaft due to the operation of a gear wheel connected with a wedge on the input shaft. The distances of the gear from the bearings are given as L₁ = 40 mm and L2 = 60 mm. In the most dangerous section, you are required to check the strength according to the S = 3 safety factor. If the section is unsafe in terms of strength, what changes would you make in the design to make it safe? (The surface of the spindle is machined as fine chips, reliability poor Kg = 1.).arrow_forwardA Steel shaft is subjected to an end thrust producing a stress of 90 MPa and the minimum shearing stress on the surface arising from torsion is 60 MPa .The yield point stress of the material in simple tension was found to be 300 MPa. calculate the factor of safety of the shaft according to the following theory 1)maximum shear stress theoryarrow_forwardThe rotating shaft running at n = 900 rpm, shown in the figure below, is machined from AISI 1045 CD steel. It is subjected to a force of F = 10.1 kN. The shaft is experiencing an operating temperature of 35 oC. With the specified loading and for the reliability of 99.9 %, Determine the minimum factor of safety for fatigue based on infinite life*. Determine the maximum safe load (Fmax) that can be applied for a factor of safety of 1.5 and a design life of 5x105 cycles, all other input values remaining the same. Determine the factor of safety against yielding.arrow_forward

- The figure shows a shaft mounted in bearings at A and D and having pulleys at B and C. The forces shown acting on the pulley surfaces represent the belt tensions. The shaft is to be made of AISI 1035 CD steel. The shaft is rotating at speed of 1000 rpm. Find the minimum factor of safety for fatigue based on infinite life. If the life is not infinite, estimate the number of cycles. Be sure to check for yielding. Take shaft diameter to be 1.5 inches.arrow_forwardThe corediameter of the double start square threaded screw having a pitch of 12mm is 50 mm. A load of 18kN is lifted through a distance of 180mm. Find the work done(in Joule)in lifting the loadand the efficiency of the screw, when 1. The load rotates with the screw, and 2. The load rests on the loose head which does not rotate with the screw. The external and internal diameter of the bearing surface of the loose head are 60 mm and 10 mmrespectively. The coefficient of friction for the screw is 0.11,whilefor the bearing surface is 0.13.arrow_forwardThe shaft shown in the figure is machined from AISI 1040 CD steel. The shaft rotates at 1600 rpm and is supported in rolling bearings at A and B. The applied forces are F1 = 1600 lbf and F2 = 640 lbf. A steady torque of 1600 lbf·in is being transmitted through the shaft between the points of application of the forces.arrow_forward

- The figure (attached) shows a belt pulley mechanism which is loaded statically. The shaft is made of AISI 1030 steel with the yield strength of 480 MPa. Using distortion energy theory (DET), determine the diameter of the shaft with a factor of safety of 2.arrow_forwardA magnesium-alloy wire of diameter d = 4mm and length L rotates inside a flexible tube in order to open or close a switch from a remote location (see figure). A torque Tis applied manually (either clockwise or counterclockwise) at end 5, thus twisting the wire inside the tube. At the other end A, the rotation of the wire operates a handle that opens or closes the switch. A torque T0 = 0.2 N · m is required to operate the switch. The torsional stiffness of the tube, combined with friction between the tube and the wire, induces a distributed torque of constant intensity t = 0.04N m/m (torque per unit distance) acting along the entire length of the wire. (a) If the allowable shear stress in the wire is T allow = 30 MPa, what is the longest permissible length Lmaxof the wire?arrow_forwardA motor driving a solid circular steel shaft with diameter d = 1.5 in, transmits 50 hp to a gear at B, The allowable shear stress in the steel is 6000 psi. Calculate the required speed of rotation (number of revolutions per minute) so that the shear stress in the shaft does not exceed the allowable limit.arrow_forward

- Two sections of steel drill pipe, joined by bolted flange plates at Ä are being tested to assess the adequacy of both the pipes. In the test, the pipe structure is fixed at A, a concentrated torque of 500 kN - m is applied at x = 0.5 m, and uniformly distributed torque intensity t1= 250 kN m/m is applied on pipe BC. Both pipes have the same inner diameter = 200 mm. Pipe AB has thickness tAB=15 mm, while pipe BC has thickness TBC= 12 mm. Find the maximum shear stress and maximum twist of the pipe and their locations along the pipe. Assume G = 75 GPa.arrow_forwardA crank arm consists of a solid segment of length bxand diameter rf, a segment of length bltand a segment of length byas shown in the figure. Two loads P act as shown: one parallel to — vand another parallel to —y. Each load P equals 1.2 kN. The crankshaft dimensions are A] = 75 mm, fr> = 125 mm, and b3= 35 mm. The diameter of the upper shaft isd = 22 mm, (a) Determine the maximum tensile, compressive, and shear stresses at point A, which is located on the surface of the shaft at the z axis. (b) Determine the maximum tensile, compressive, and shear stresses at point B, which is located on the surface of the shaft at the y axisarrow_forwardCalculate the maximum tensile stress developed in a 1/4-20 bolt (Major dia = 0.2500" and Root dia = 0.1959"), 3" long, and a head height of 0.1875", if it is subjected to a load of 426 lbs.arrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning