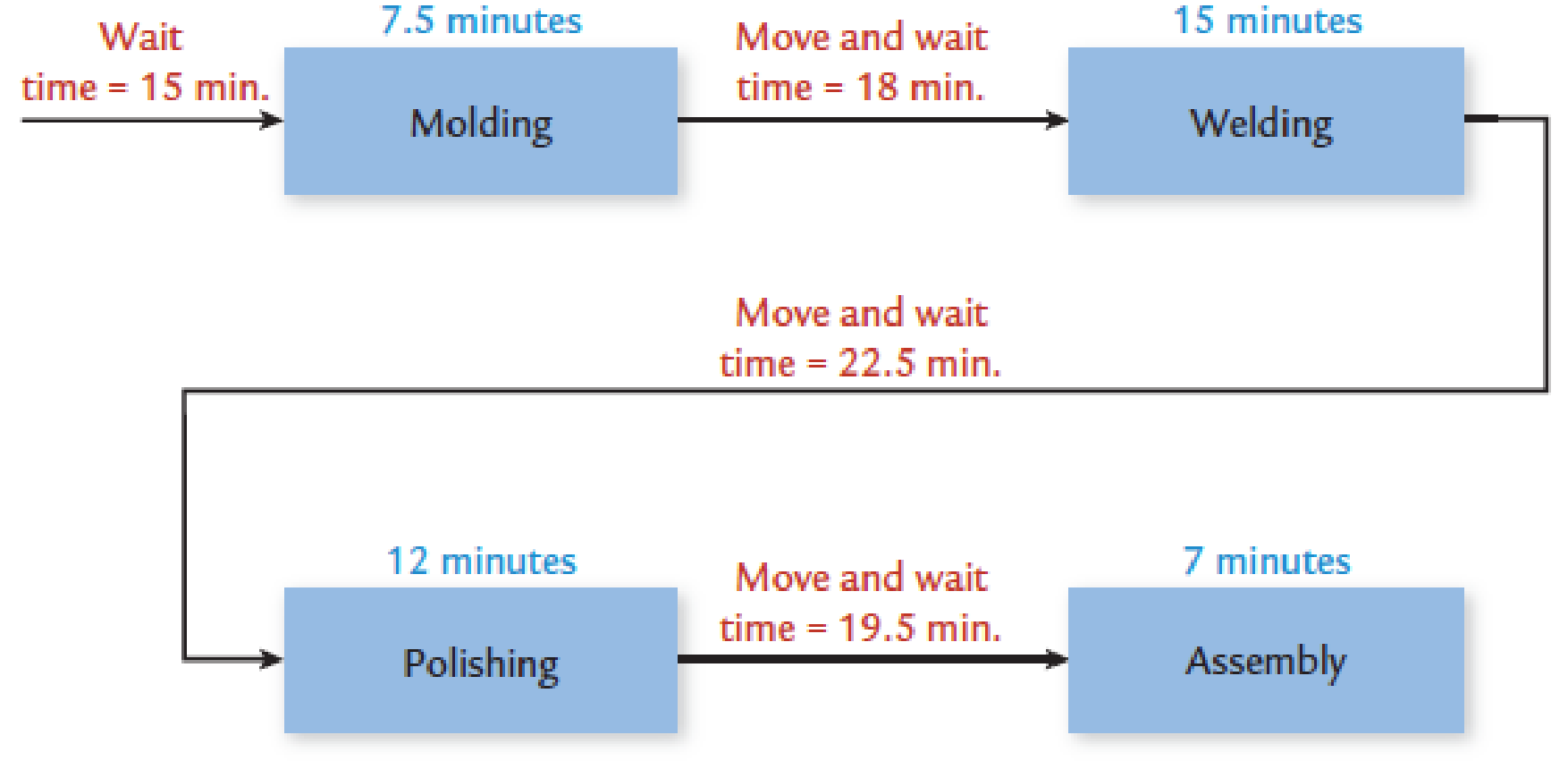

Anderson Company has the following departmental manufacturing structure for one of its products:

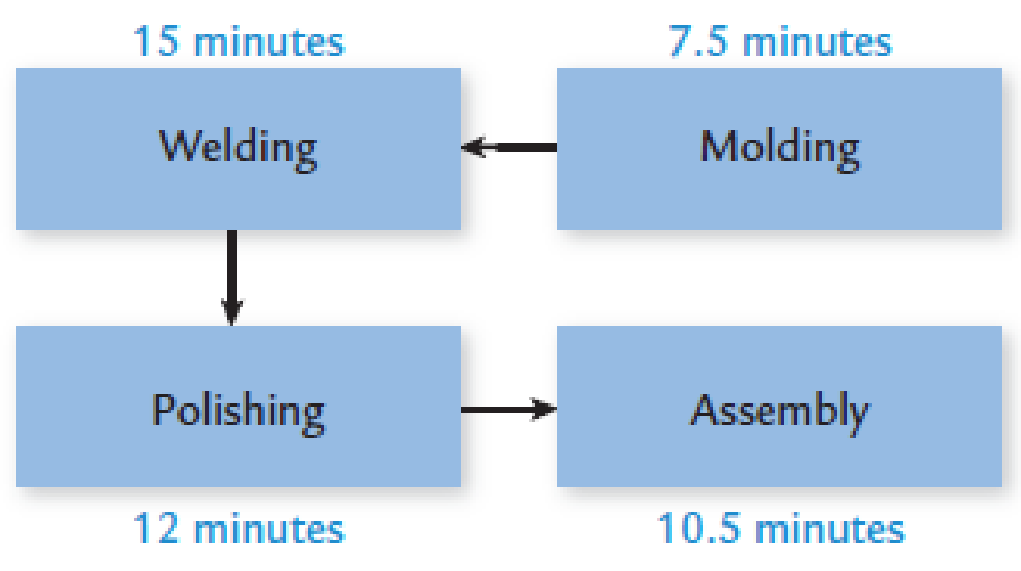

After some study, the production manager of Anderson recommended the following revised cellular manufacturing approach:

Required:

- 1. Calculate the total time it takes to produce a batch of 20 units using Anderson’s traditional departmental structure.

- 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate?

- 3. What if the processing times of molding, welding, and assembly are all reduced to six minutes each? What is the production rate now, and how long will it take to produce a batch of 20 units?

1.

Compute the total time taken for the production of a batch of 20 units using the traditional departmental structure.

Explanation of Solution

Traditional departmental structure: The traditional departmental structure refers to the conventional manufacturing approach, wherein the manufacturing is a process which includes lots of lead time.

Compute the total time taken for the production of a batch of 20 units using the traditional departmental structure.

| Batch Time: | |

| Processing time: | |

| Molding (1) | 150 mins |

| Welding (2) | 300 mins |

| Polishing (3) | 240 mins |

| Assembly (4) | 140 mins |

| Total Processing Time | 830 mins |

| Move and wait time (5) | 75 mins |

| Total Batch Time | 905 mins |

Table (1)

Working Notes (1):

Calculate the processing time for Molding:

Working Notes (2):

Calculate the processing time for Welding:

Working Notes (3):

Calculate the processing time for Polishing:

Working Notes (4):

Calculate the processing time for Assembly:

Working Notes (5):

Calculate the Move and wait time:

2.

Compute the total time taken for the production of a batch of 20 units using the cellular manufacturing approach and the production rate if it’s a continuous production and identify the process which controls the production rate.

Explanation of Solution

Cellular manufacturing: The cellular manufacturing refers to the manufacturing approach, wherein the various equipments related to the various processes of production are clustered together to avoid any move time and enable faster manufacturing of the goods.

Compute the total time taken for the production of a batch of 20 units using the cellular manufacturing.

| Batch Time: | |

| Processing time: | |

| For First Unit | 45 mins |

| Second unit | 60 mins |

| Third Unit | 75 mins |

| Fourth unit | 90 mins |

| Fifth Unit | 105 mins |

| Sixth unit | 120 mins |

| Seventh Unit | 135 mins |

| Eighth unit | 150 mins |

| Ninth Unit | 165 mins |

| Tenth unit | 180 mins |

| Eleventh Unit | 195 mins |

| Twelfth unit | 210 mins |

| Thirteenth Unit | 225 mins |

| Fourteenth Unit | 240 mins |

| Fifteenth Unit | 255 mins |

| Sixteenth Unit | 270 mins |

| Seventeenth Unit | 285 mins |

| Eighteenth Unit | 300 mins |

| Nineteenth Unit | 315 mins |

| Twentieth Unit | 330 mins |

| Total Processing Time | 330 mins |

Table (2)

The total processing time of 1 unit is 45 minutes (refer Working Notes (6)). The production of the second unit starts once in every fifteen minutes, so that the production process can go on without stopping in middle. Thus 15 mins is added to the processing time of previous every unit, to get the processing time of the present unit.

The production time for a batch of 20 units using cellular manufacturing is 330 mins. The production of 20 units under the traditional departmental structure has a production time is 905 mins. Hence, the total production time saved using the cellular manufacturing approach is 605 mins

The production rate uses the processing time of the process with the longest processing time, thus the Welding process with 15 mins processing time is used.

The new Production rate is 4 units per hour

The production of every unit starts once in fifteen minutes and for 20 units the production time is 300 mins

The production starts once in every fifteen minutes, as Welding process takes 15 mins to be completed and is the bottleneck process in the production, as it controls the production rate.

Working Notes (6):

Calculate the total Processing time:

3.

Identify the new processing time and the production rate if the processing time for welding, molding and assembly are reduced by 6 minutes each.

Explanation of Solution

The production rate uses the processing time of the process with the longest processing time, thus the Polishing process with 12 mins processing time is used.

The new Production rate is 5 units per hour

The production of every unit starts once in twelve minutes and for 20 units the production time is 240 mins

Compute the new total processing time for the production of a batch of 20.

| Batch Time: | |

| Processing time: | |

| For First Unit | 27 mins |

| Second unit | 39 mins |

| Third Unit | 51 mins |

| Fourth unit | 63 mins |

| Fifth Unit | 75 mins |

| Sixth unit | 87 mins |

| Seventh Unit | 99 mins |

| Eighth unit | 111 mins |

| Ninth Unit | 123 mins |

| Tenth unit | 135 mins |

| Eleventh Unit | 147 mins |

| Twelfth unit | 159 mins |

| Thirteenth Unit | 171 mins |

| Fourteenth Unit | 183 mins |

| Fifteenth Unit | 195 mins |

| Sixteenth Unit | 207 mins |

| Seventeenth Unit | 219 mins |

| Eighteenth Unit | 231 mins |

| Nineteenth Unit | 243 mins |

| Twentieth Unit | 255 mins |

| Total Processing Time | 255 mins |

Table (3)

The total processing time of 1 unit is 27 minutes (refer Working Notes (7)). The production of the second unit starts once in every twelfth minutes, so that the production process can go on without stopping in middle. Thus 12 mins is added to the processing time of previous every unit, to get the processing time of the present unit.

The production time for a batch of 20 units using cellular manufacturing is 255 mins.

Working Notes (7):

Calculate the total Processing time:

Want to see more full solutions like this?

Chapter 15 Solutions

CengageNOWv2, 1 term Printed Access Card for Hansen/Mowen’s Cornerstones of Cost Management, 4th

- Gumbrecht Company has the following departmental manufacturing layout for one of its plants: A consulting firm has recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 20 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Casting is reduced to 9 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 20 units if the cell is in a continuous production mode?arrow_forwardMabbut Company has the following departmental manufacturing layout for one of its plants: A consulting firm recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 10 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 10 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Welding is reduced to 6 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 10 units if the cell is in a continuous production mode?arrow_forwardBienestar Inc., has the following departmental structure for producing a well-known multivitamin: A consultant designed the following cellular manufacturing structure for the same product: The times above the processes represent the time required to process one unit of product. Required: 1. Calculate the time required to produce a batch of 15 bottles using a batch-processing departmental structure. 2. Calculate the time to process 15 units using cellular manufacturing. 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 15 units?arrow_forward

- Erba Inc. has the following departmental layout for producing an herbal supplement: After a detailed study, the head of the plants industrial engineering department recommended that the following cellular manufacturing layout replace the current departmental structure: Required: 1. Calculate the time required to produce a batch of 12 bottles using a batch processing departmental structure. 2. Calculate the time to process 12 units using cellular manufacturing. 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 12 units? 4. How many units can the cell produce per hour, assuming the cell is producing on a continuous basis? 5. What must happen so that the cell can produce 12 units per hour, assuming the cell produces on a continuous basis?arrow_forwardYoung Company is beginning operations and is considering three alternatives to allocate manufacturing overhead to individual units produced. Young can use a plantwide rate, departmental rates, or activity-based costing. Young will produce many types of products in its single plant, and not all products will be processed through all departments. In which one of the following independent situations would reported net income for the first year be the same regardless of which overhead allocation method had been selected? a. All production costs approach those costs that were budgeted. b. The sales mix does not vary from the mix that was budgeted. c. All manufacturing overhead is a fixed cost. d. All ending inventory balances are zero.arrow_forwardKagle design engineers are in the process of developing a new green product, one that will significantly reduce impact on the environment and yet still provide the desired customer functionality. Currently, two designs are being considered. The manager of Kagle has told the engineers that the cost for the new product cannot exceed 550 per unit (target cost). In the past, the Cost Accounting Department has given estimated costs using a unit-based system. At the request of the Engineering Department, Cost Accounting is providing both unit-and activity-based accounting information (made possible by a recent pilot study producing the activity-based data). Unit-based system: Variable conversion activity rate: 100 per direct labor hour Material usage rate: 20 per part ABC system: Labor usage: 15 per direct labor hour Material usage (direct materials): 20 per part Machining: 75 per machine hour Purchasing activity: 150 per purchase order Setup activity: 3,000 per setup hour Warranty activity: 500 per returned unit (usually requires extensive rework) Customer repair cost: 25 per repair hour (average) Required: 1. Select the lower-cost design using unit-based costing. Are logistical and post-purchase activities considered in this analysis? 2. Select the lower-cost design using ABC analysis. Explain why the analysis differs from the unit-based analysis. 3. What if the post-purchase cost was an environmental contaminant and amounted to 10 per unit for Design A and 40 per unit for Design B? Assume that the environmental cost is borne by society. Now which is the better design?arrow_forward

- Bienestar, Inc., implemented cellular manufacturing as recommended by a consultant. The production flow improved dramatically. However, the company was still faced with the competitive need to improve its cycle time so that the production rate is one bottle every four minutes (15 bottles per hour). The cell structure is shown below; the times above the process represent the time required to process one unit. Required: 1. How many units can the cell produce per hour (on a continuous running basis)? 2. How long does it take the cell to produce one unit, assuming the cell is producing on a continuous basis? 3. What must happen so that the cell can produce one bottle every four minutes or 15 per hour, assuming the cell produces on a continuous basis?arrow_forwardA dedicated pharmaceutical plant uses the theory of constraints and has three processes: Mixing, Encapsulating, and Packaging. For Mixing, sufficient materials are released to produce 4,000 packages of product per day. Encapsulating has a buffer inventory of 8,000 units (work in process from Mixing). Packaging produces 4,000 units per day. Which of the three processes sets the production rate of 4,000 units per day? a. The Mixing Department b. The Encapsulating Department c. The Packaging Department d. Cannot be determinedarrow_forwardCalculate lead time Williams Optical Inc. is considering a new lean product cell. The present manufacturing approach produces a product in four separate steps. The production batch sizes are 45 units. The process time for each step is as follows: The time required to move each batch between steps is 5 minutes. In addition, the time to move raw materials to Process Step 1 is also 5 minutes, and the time to move completed units from Process Step 4 to finished goods inventory is 5 minutes. The new lean layout will allow the company to reduce the batch sizes from 45 units to 3 units. The time required to move each batch between steps and the inventory locations will be reduced to 2 minutes. The processing time in each step will stay the same. Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the (A) present and (B) proposed production approaches. (Round percentages to one decimal place.)arrow_forward

- Evans, Inc., has a unit-based costing system. Evanss Miami plant produces 10 different electronic products. The demand for each product is about the same. Although they differ in complexity, each product uses about the same labor time and materials. The plant has used direct labor hours for years to assign overhead to products. To help design engineers understand the assumed cost relationships, the Cost Accounting Department developed the following cost equation. (The equation describes the relationship between total manufacturing costs and direct labor hours; the equation is supported by a coefficient of determination of 60 percent.) Y=5,000,000+30X,whereX=directlaborhours The variable rate of 30 is broken down as follows: Because of competitive pressures, product engineering was given the charge to redesign products to reduce the total cost of manufacturing. Using the above cost relationships, product engineering adopted the strategy of redesigning to reduce direct labor content. As each design was completed, an engineering change order was cut, triggering a series of events such as design approval, vendor selection, bill of materials update, redrawing of schematic, test runs, changes in setup procedures, development of new inspection procedures, and so on. After one year of design changes, the normal volume of direct labor was reduced from 250,000 hours to 200,000 hours, with the same number of products being produced. Although each product differs in its labor content, the redesign efforts reduced the labor content for all products. On average, the labor content per unit of product dropped from 1.25 hours per unit to one hour per unit. Fixed overhead, however, increased from 5,000,000 to 6,600,000 per year. Suppose that a consultant was hired to explain the increase in fixed overhead costs. The consultants study revealed that the 30 per hour rate captured the unit-level variable costs; however, the cost behavior of other activities was quite different. For example, setting up equipment is a step-fixed cost, where each step is 2,000 setup hours, costing 90,000. The study also revealed that the cost of receiving goods is a function of the number of different components. This activity has a variable cost of 2,000 per component type and a fixed cost that follows a step-cost pattern. The step is defined by 20 components with a cost of 50,000 per step. Assume also that the consultant indicated that the design adopted by the engineers increased the demand for setups from 20,000 setup hours to 40,000 setup hours and the number of different components from 100 to 250. The demand for other non-unit-level activities remained unchanged. The consultant also recommended that management take a look at a rejected design for its products. This rejected design increased direct labor content from 250,000 hours to 260,000 hours, decreased the demand for setups from 20,000 hours to 10,000 hours, and decreased the demand for purchasing from 100 component types to 75 component types, while the demand for all other activities remained unchanged. Required: 1. Using normal volume, compute the manufacturing cost per labor hour before the year of design changes. What is the cost per unit of an average product? 2. Using normal volume after the one year of design changes, compute the manufacturing cost per hour. What is the cost per unit of an average product? 3. Before considering the consultants study, what do you think is the most likely explanation for the failure of the design changes to reduce manufacturing costs? Now use the information from the consultants study to explain the increase in the average cost per unit of product. What changes would you suggest to improve Evanss efforts to reduce costs? 4. Explain why the consultant recommended a second look at a rejected design. Provide computational support. What does this tell you about the strategic importance of cost management?arrow_forwardJolene Askew, manager of Feagan Company, has committed her company to a strategically sound cost reduction program. Emphasizing life-cycle cost management is a major part of this effort. Jolene is convinced that production costs can be reduced by paying more attention to the relationships between design and manufacturing. Design engineers need to know what causes manufacturing costs. She instructed her controller to develop a manufacturing cost formula for a newly proposed product. Marketing had already projected sales of 25,000 units for the new product. (The life cycle was estimated to be 18 months. The company expected to have 50 percent of the market and priced its product to achieve this goal.) The projected selling price was 20 per unit. The following cost formula was developed: Y=200,000+10X1 where X1=Machinehours(Theproductisexpectedtouseonemachinehourforeveryunitproduced.) Upon seeing the cost formula, Jolene quickly calculated the projected gross profit to be 50,000. This produced a gross profit of 2 per unit, well below the targeted gross profit of 4 per unit. Jolene then sent a memo to the Engineering Department, instructing them to search for a new design that would lower the costs of production by at least 50,000 so that the target profit could be met. Within two days, the Engineering Department proposed a new design that would reduce unit-variable cost from 10 per machine hour to 8 per machine hour (Design Z). The chief engineer, upon reviewing the design, questioned the validity of the controllers cost formula. He suggested a more careful assessment of the proposed designs effect on activities other than machining. Based on this suggestion, the following revised cost formula was developed. This cost formula reflected the cost relationships of the most recent design (Design Z). Y=140,000+8X1+5,000X2+2,000X3 where X1=MachinehoursX2=NumberofbatchesX3=Numberofengineeringchangeorders Based on scheduling and inventory considerations, the product would be produced in batches of 1,000; thus, 25 batches would be needed over the products life cycle. Furthermore, based on past experience, the product would likely generate about 20 engineering change orders. This new insight into the linkage of the product with its underlying activities led to a different design (Design W). This second design also lowered the unit-level cost by 2 per unit but decreased the number of design support requirements from 20 orders to 10 orders. Attention was also given to the setup activity, and the design engineer assigned to the product created a design that reduced setup time and lowered variable setup costs from 5,000 to 3,000 per setup. Furthermore, Design W also creates excess activity capacity for the setup activity, and resource spending for setup activity capacity can be decreased by 40,000, reducing the fixed cost component in the equation by this amount. Design W was recommended and accepted. As prototypes of the design were tested, an additional benefit emerged. Based on test results, the post-purchase costs dropped from an estimated 0.70 per unit sold to 0.40 per unit sold. Using this information, the Marketing Department revised the projected market share upward from 50 percent to 60 percent (with no price decrease). Required: 1. Calculate the expected gross profit per unit for Design Z using the controllers original cost formula. According to this outcome, does Design Z reach the targeted unit profit? Repeat, using the engineers revised cost formula. Explain why Design Z failed to meet the targeted profit. What does this say about the use of unit-based costing for life-cycle cost management? 2. Calculate the expected profit per unit using Design W. Comment on the value of activity information for life-cycle cost management. 3. The benefit of the post-purchase cost reduction of Design W was discovered in testing. What direct benefit did it create for Feagan Company (in dollars)? Reducing post-purchase costs was not a specific design objective. Should it have been? Are there any other design objectives that should have been considered?arrow_forwardA company is considering a special order for 1,000 units to be priced at 8.90 (the normal price would be 11.50). The order would require specialized materials costing 4.00 per unit. Direct labor and variable factory overhead would cost 2.15 per unit. Fixed factory overhead is 1.20 per unit. However, the company has excess capacity, and acceptance of the order would not raise total fixed factory overhead. The warehouse, however, would have to add capacity costing 1,300. Which of the following is relevant to the special order? a. 11.50 b. 1.20 c. 7.35 d. 8.90arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning